Automatic magnetic rapid locking chuck

An automatic and quick-locking technology, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of the screwdriver head falling off the outside of the mandrel, falling to the ground, losing the screwdriver head, etc., achieving ingenious design, safe use, and avoiding loss. and damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

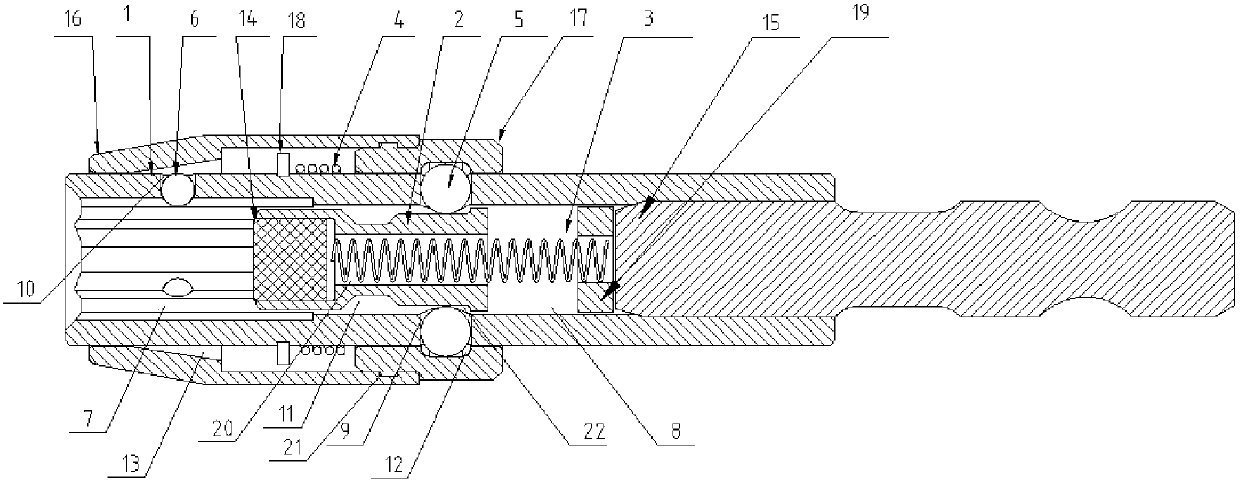

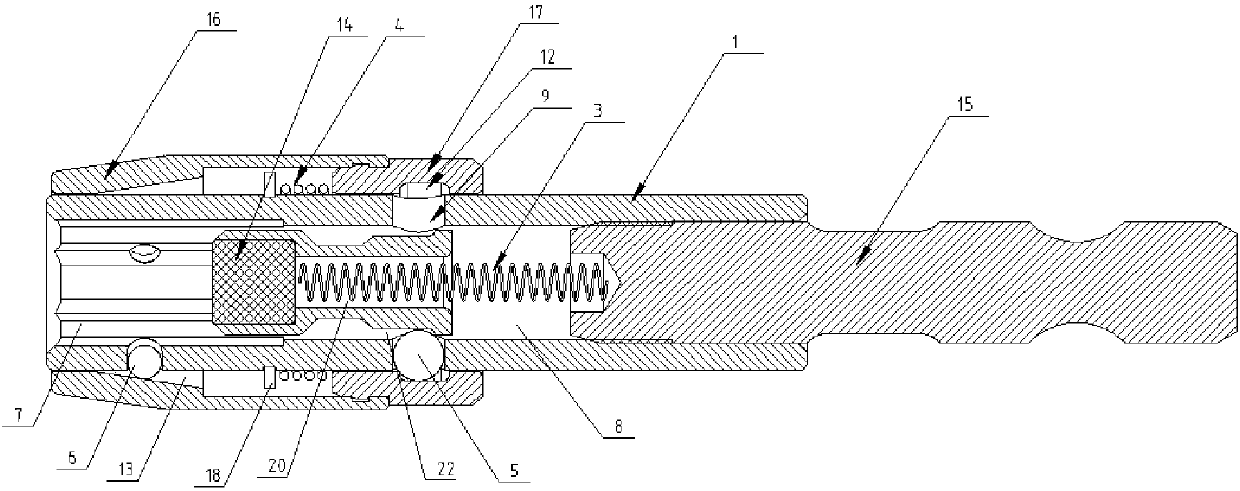

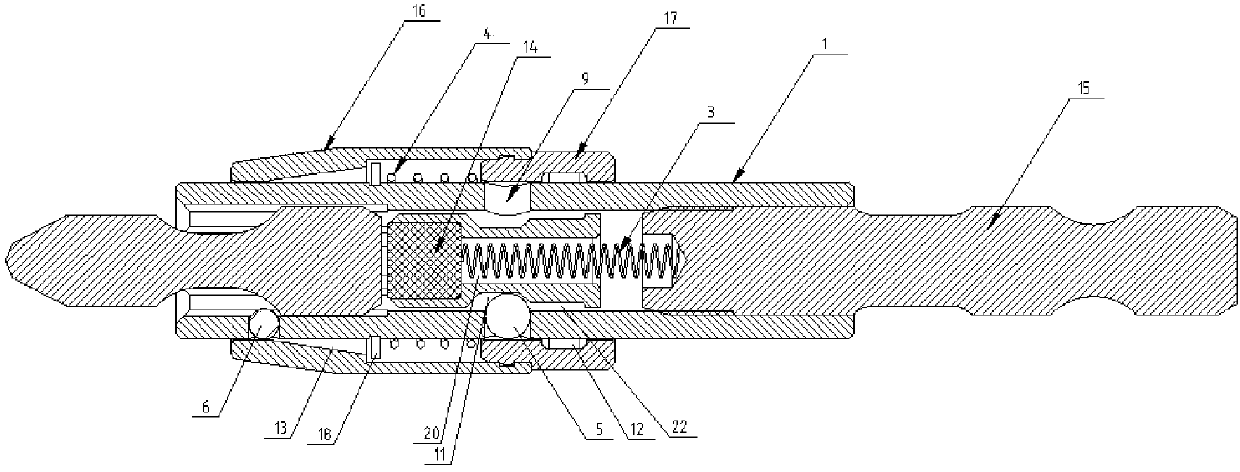

[0018] Embodiment: A magnetic automatic quick-lock chuck, including a mandrel, an outer sleeve, a sliding pin 2, a first elastic member 3, a second elastic member 4, a first slider 5 and a second slider 6, the mandrel One end is formed with a prism hole 7 for inserting the bit of a screwdriver, the bottom of the prism hole 7 is connected with a blind hole 8, and the side wall of the blind hole 8 of the mandrel is provided with at least two first radial perforations extending radially along the mandrel 9. There are at least two second radial perforations 10 extending radially along the mandrel axis on the side wall of the prism hole 7, and the first slider 5 can slide axially along the first radial perforations 9 and be positioned in the first radial perforations. 9, the second slider 6 can be axially slid and positioned in the second radial perforation 10 along the second radial perforation 10, and the two ends of the first and second sliders can extend out of the first and sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com