Steel dam gate device with anti-slipping-down function

An anti-slip, functional technology, applied in the sequence/logic controller in the direction of program control, program control, marine engineering, etc., can solve the problem that the locking cylinder cannot lock the rocker arm smoothly, and the rocker arm cannot be accurately changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

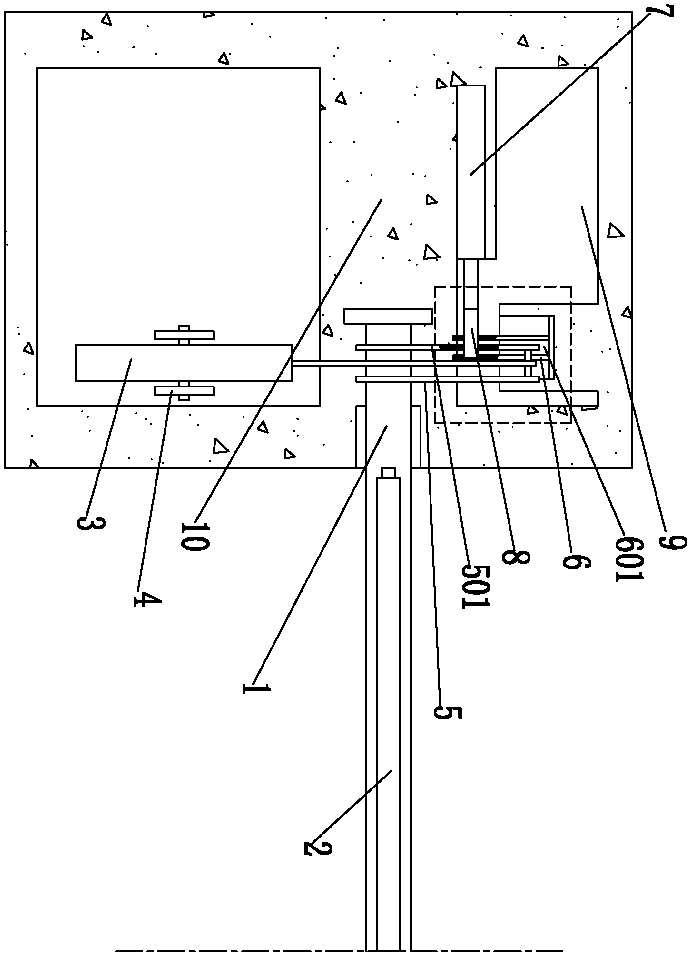

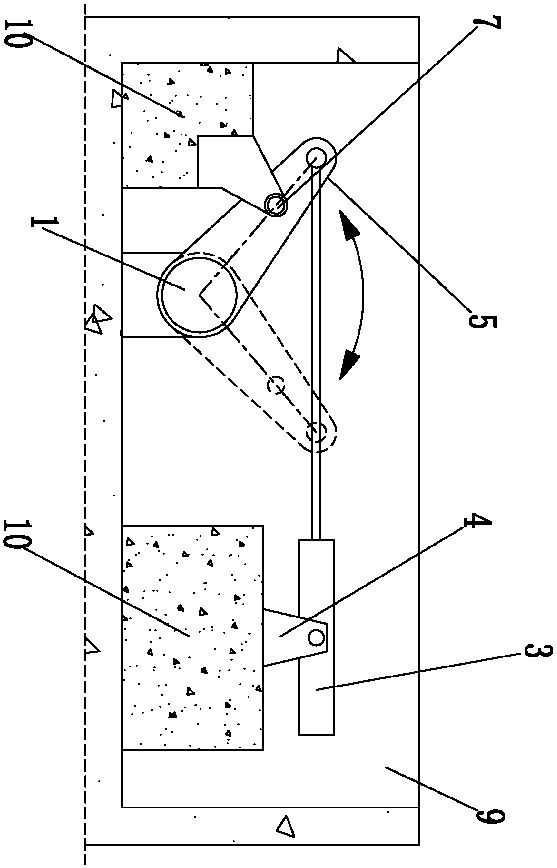

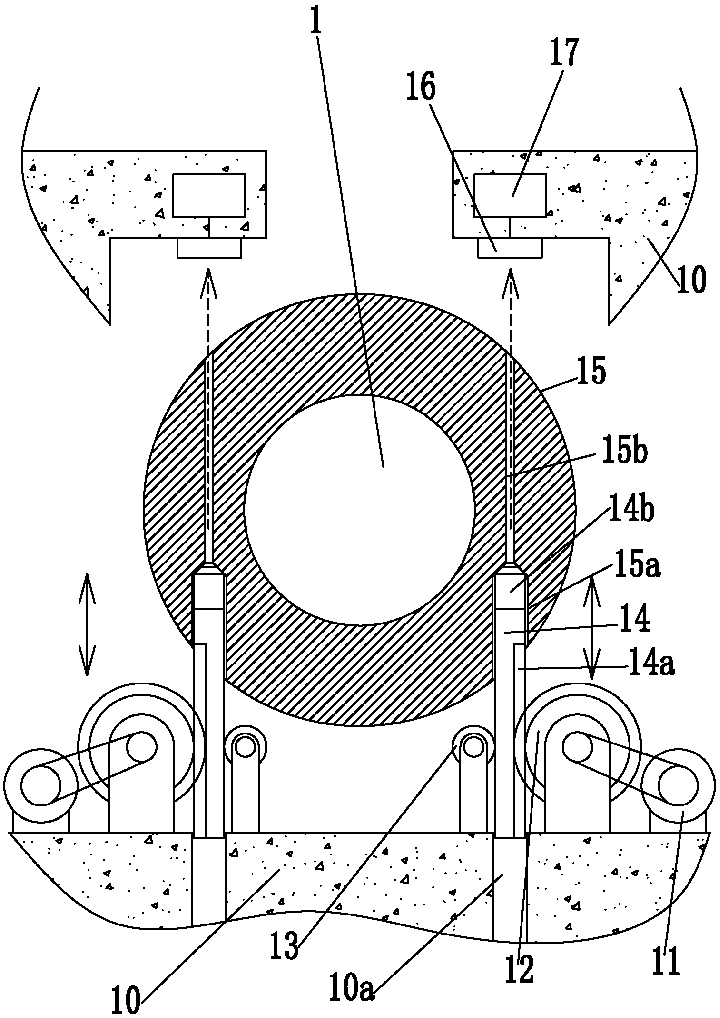

[0018] Such as figure 1 , 2 , 5, and 6, the steel dam gate device with anti-sliding function includes a horizontal central rotating shaft 1, a gate plate 2 installed on the central rotating shaft 1, and a pair of The control room 9 also includes a PLC controller 19 and a hydraulic system 18 controlled by the PLC controller 19. The control room 9 is provided with an indoor foundation 10, and the end of the central shaft 1 rotatably passes through the control room 9 and rotatably passes through the control room 9. Installed on the indoor foundation 10, each control room 9 is equipped with a swing oil cylinder 3, a main hinge seat 4, a rocker arm 5, and a locking oil cylinder 7, and the control room 9 is also equipped with a lock for locking the position of the rocker arm 5, and a lock The piston rod of the oil cylinder 7 is coaxially spliced with the lock pin 8, the main hinge seat 4, and the cylinder barrel of the lock cylinder 7 are all fixedly installed on the indoor found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com