A structure and method for oil and gas mixed transportation suitable for large flow and wide range of gas-oil ratio

A wide-ranging technology for oil and gas mixed transportation, used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc. handling issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

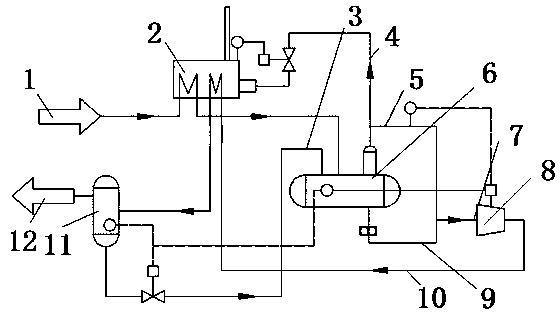

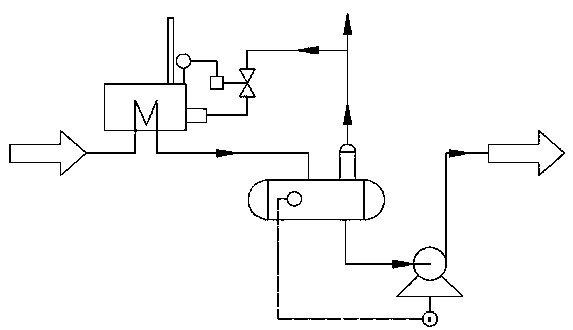

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0024] Option One:

[0025] An oil-gas mixed transportation method suitable for a large flow rate and a wide range of gas-oil ratio, characterized in that it includes the following steps, the oil and associated gas mixture extracted from the upstream oil well enters the heating furnace to be heated, and then enters the inlet buffer tank for gas-liquid separation; Part of the separated gas is used as fuel gas for the heating furnace, and the other part enters the inlet of the twin-screw pump, mixes with the liquid pressurized by the feeding pump at the bottom of the separator, enters the twin-screw pump, increases the pressure, and then enters the heating furnace for water bath treatment. Then enter the outlet buffer tank, and the pressurized oil and gas are mixed and sent out; when the inlet liquid volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com