Method for increasing condensate oil recovery ratios of condensate gas reservoirs by means of gas injection vertical displacement

A technology of condensate gas reservoir and recovery factor, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of increasing the swept volume of gas injection, not considering the difference of fluid physical properties, and high gas-oil ratio , to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

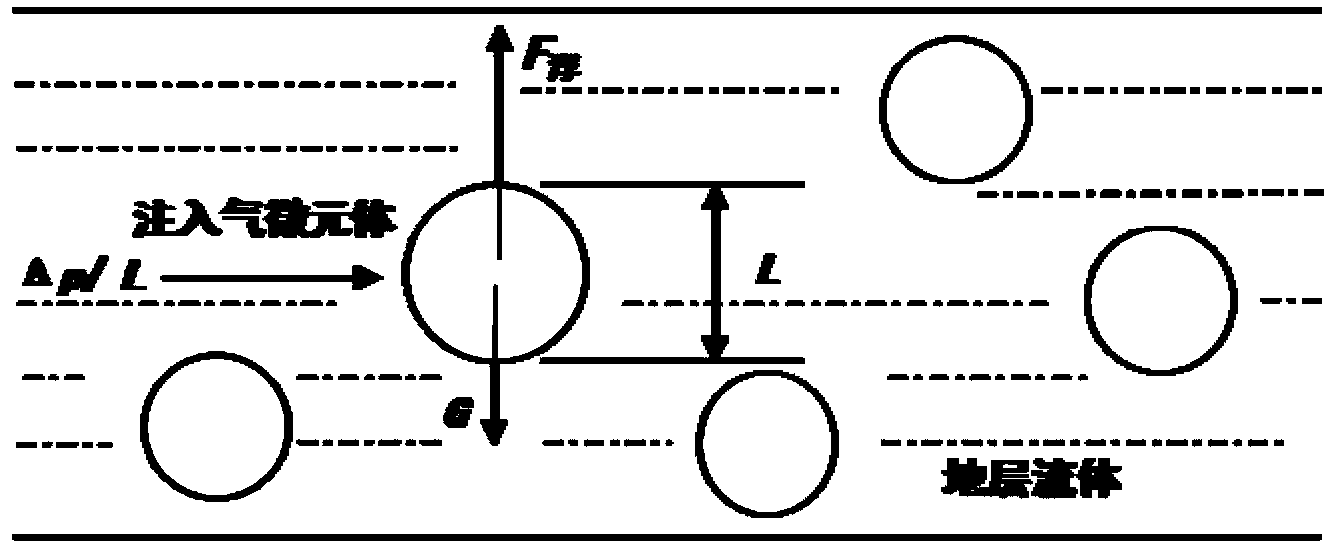

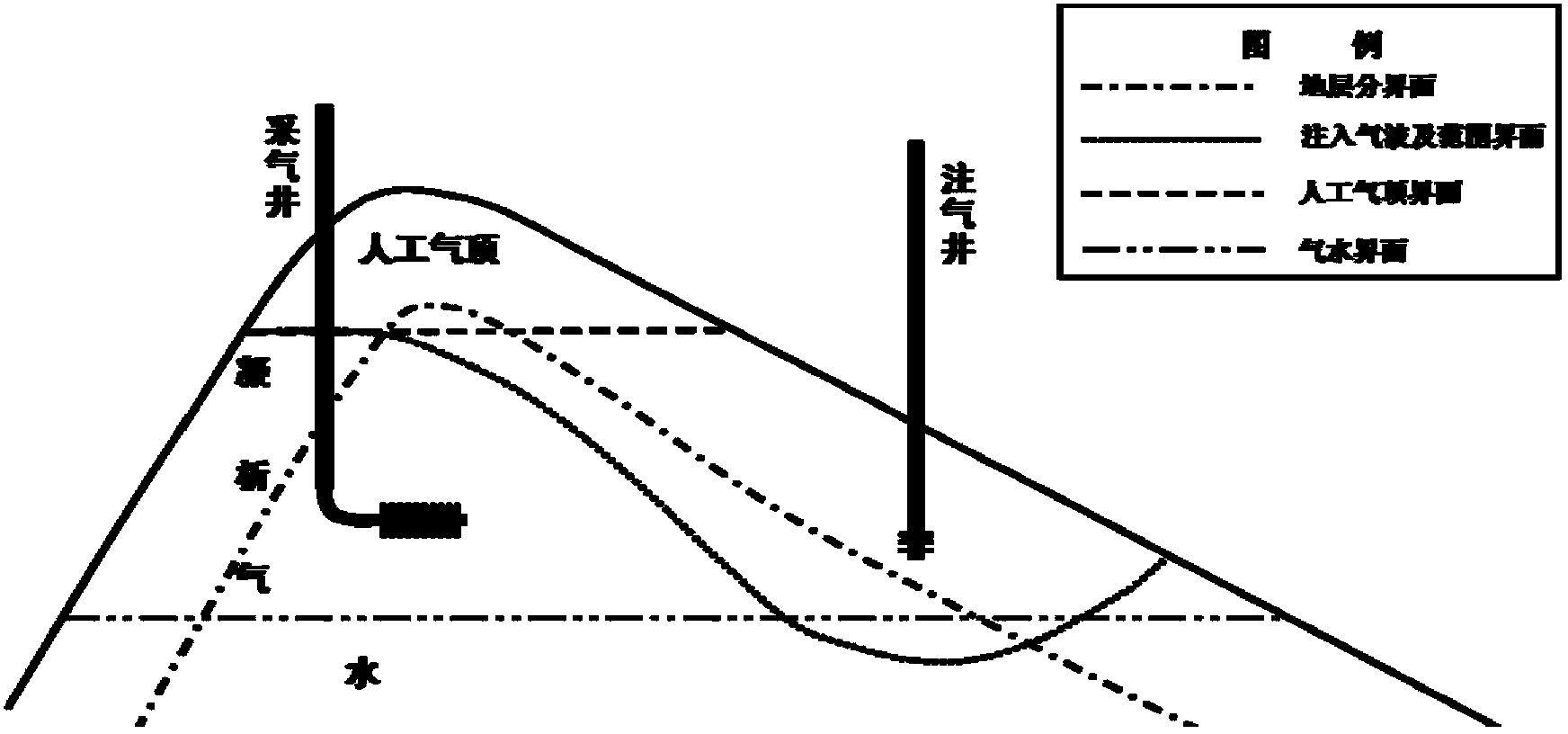

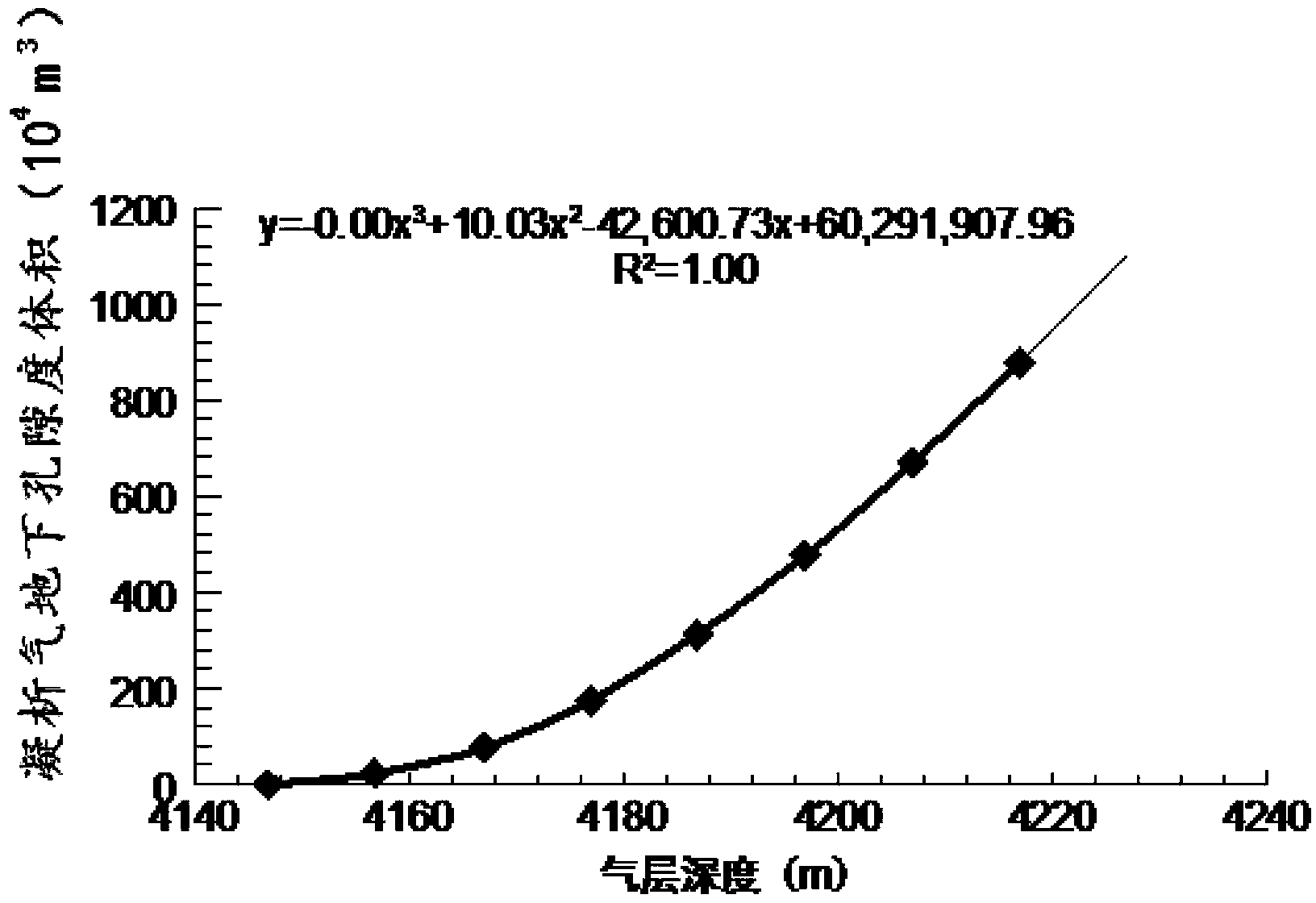

[0042] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown in Fig. 1, a method for enhancing condensate oil recovery in condensate gas reservoirs by vertical displacement of gas injection,

[0043] Aiming at the above three major problems in the exploitation of condensate gas reservoirs by gas injection, a method for improving condensate oil recovery in condensate gas reservoirs by vertical displacement of gas injection is provided; The difference in fluid physical properties can improve the sweep coefficient of injected gas in the formation and can effectively reduce the occurrence of gas channeling, and ultimately can significantly improve the utilization rate of injected gas and the ultimate recovery of condensate oil.

[0044] Taking the injection-production well group Y of a certain gas reservoir as an example, there is currently an injection well A in the injection-production well group, and two production wells are located at the east...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com