Energy-saving device with high-pressure liquid storage and supply function and low-pressure gas-liquid separation function

A technology of low-pressure gas-liquid separation and high-pressure liquid storage, applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc. , The effect of preventing the liquid supply from being gassed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

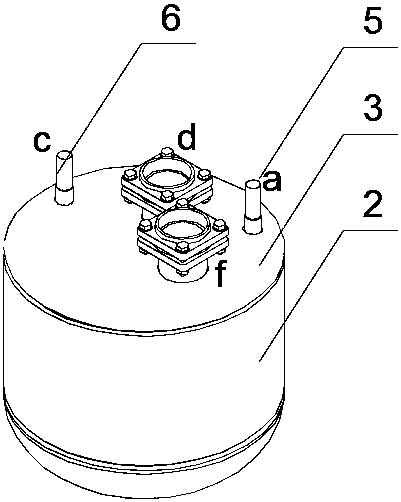

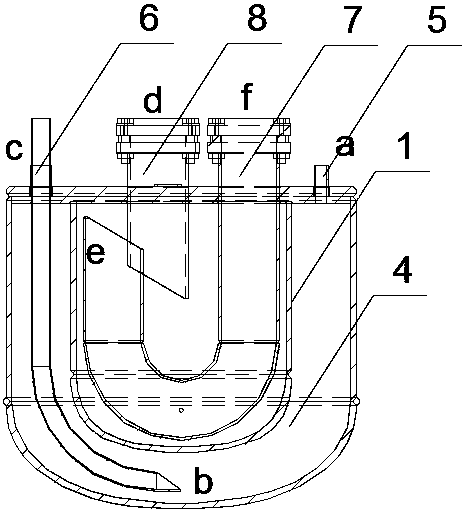

[0012] Such as Figure 1-2 As shown, an economizer with high-pressure liquid storage and liquid supply and low-pressure gas-liquid separation functions includes an inner cylinder 1 and an outer cylinder 2 coaxially arranged, the tops of the inner and outer cylinders are flush and sealed by a flat cover 3, and the inner and outer cylinders are sealed by a flat cover 3. The outer cylinder is composed of a cylinder section and a hemispherical head installed at the bottom of the cylinder section. The outer side of the inner cylinder and the inner side of the outer cylinder form a clamping cavity 4; the clamping cavity 4 is provided with a liquid inlet pipe 5 and a liquid outlet pipe 6. The top a protrudes from the flat cover 3 and is connected to the output end of the compressor, the bottom end of the inlet pipe slightly extends into the clamp ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com