Free-flying model jet test device

A test device and model technology, which is applied in the field of free-flying model jet test device, can solve the problems of air source installation, guidance, triggering, and free-flying model can not carry out active flow control, so as to prevent high-pressure gas leakage and good sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

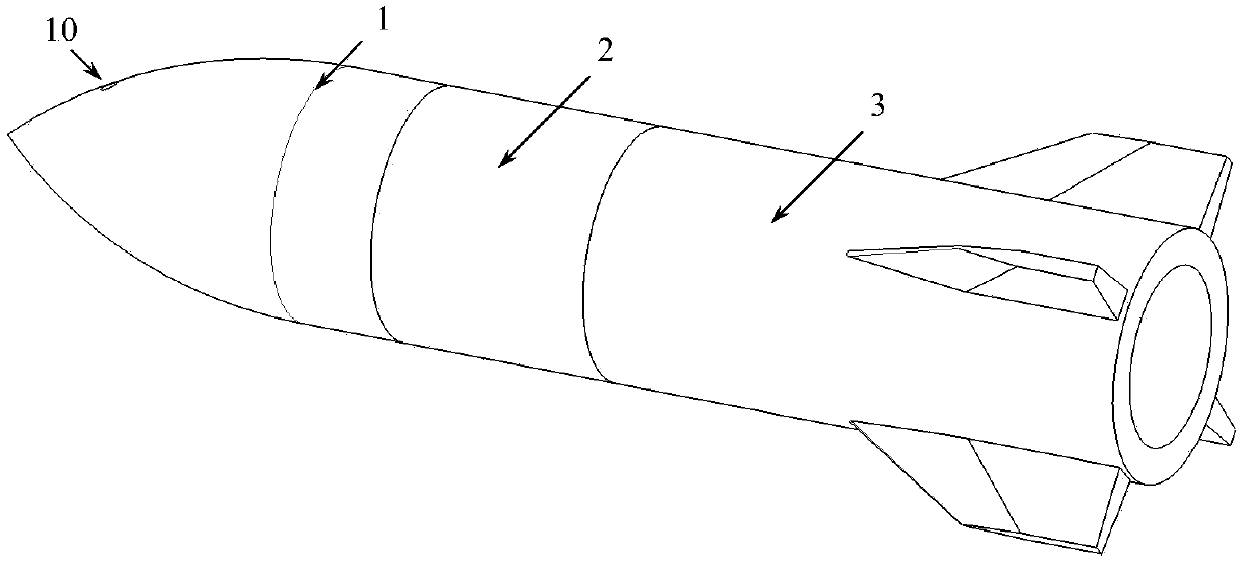

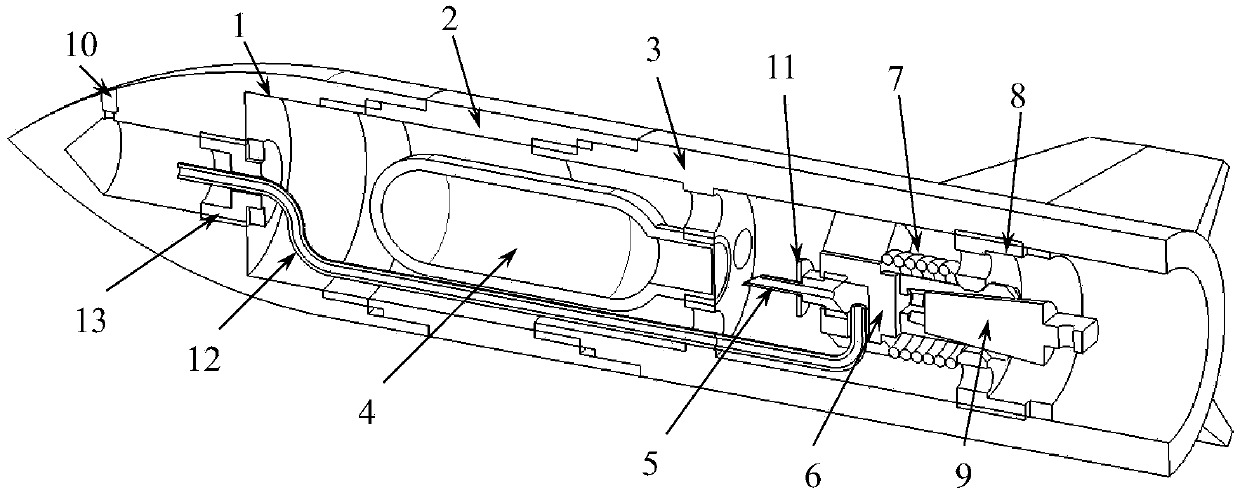

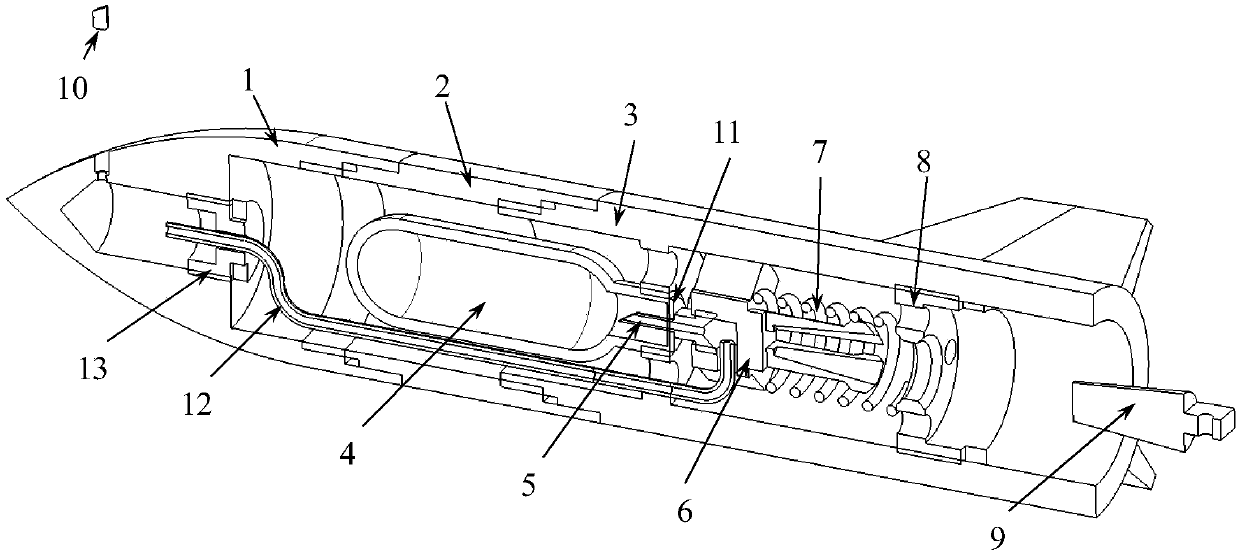

[0030] In this embodiment, the nozzle of the free-flying model jet test device is set on the model head 1 . The model head 1 is conical, the conical surface is an arc surface, the middle part 2 of the model, and the tail part 3 of the model are both cylindrical structures, and the tail part 3 of the model has an empennage at the end; The central axis is provided with a model head blind hole 1-2, and the side wall of the model head 1 is provided with a model head step hole 1-1, and the model head step hole 1-1 is connected with the blind end of the model head blind hole 1-2 , the spout modification block 10 is installed in the step hole 1-1 of the model head, the compressed gas cylinder 4 and the air injection mechanism are installed in the inner cavity of the model, and the compressed gas cylinder 4 is controlled by the air injection mechanism to generate gas, and the spout modification block 10 is in the gas Move to the outside of model head 1 under action. Guide tube fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com