Sheet arched clamp spring front and back identification device and identification method thereof

A positive and negative identification, circlip technology, applied in measuring devices, instruments, program control in sequence/logic controllers, etc., can solve the problems of employees' eyestrain and unfavorable production capacity, so as to reduce the burden on the heart and prevent the waste of accessories , the effect of preventing product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

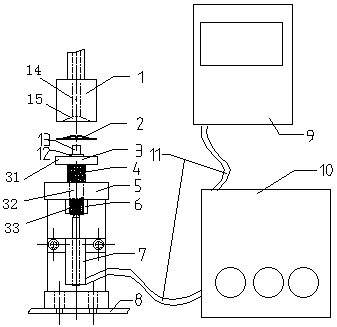

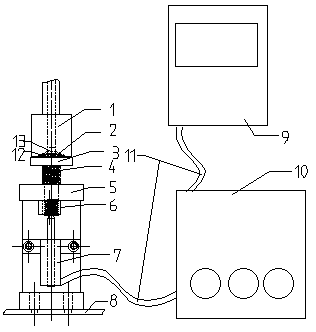

[0025] Such as Figure 1~2 As shown, a device for identifying the front and back of a sheet arched circlip disclosed by the present invention includes a base 8, a support platform 5, a linear displacement sensor 7, a circlip support platform 3, a spring 4, a suction head 1, and a PLC control box 10 and touch screen 9.

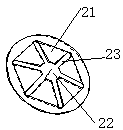

[0026] Specifically, the support platform 5 is installed on the base 8, and there is a through slide hole (not shown in the figure) on the platform. The circlip support platform 3 includes a supporting platform 31, a sliding column 32 located on the back of the supporting platform, And the lower end of the sliding column 32 has an external thread 33, the upper end surface of the support table has a raised gain boss 12, and the gain boss is provided with a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com