A High Precision Horizontal Axis Silicon Micro Gyroscope Based on Tuning Fork Driving Effect

A silicon micro-gyroscope, high-precision technology, applied in gyro effect for speed measurement, gyroscope/steering sensing equipment, instruments, etc., can solve the high coupling degree of single-chip integrated three-axis gyroscope, which is not conducive to the miniaturization of micro-inertial system , Restricting the development and application of micro-inertial devices and other issues, to achieve the effect of improving detection sensitivity, improving structural quality factor, and high detection capacitance sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although the present disclosure is shown in the

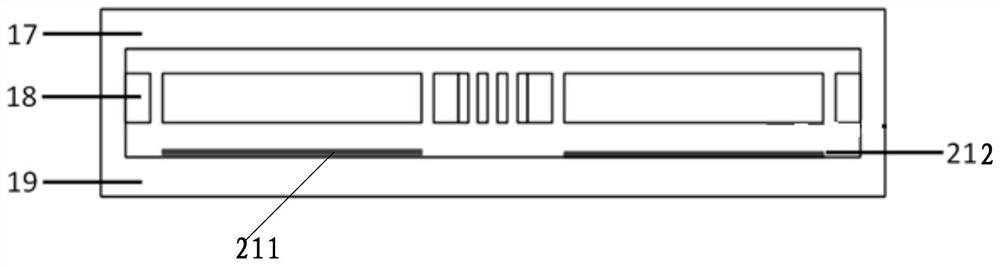

[0031] The working environment of the gyroscope sensitive structure 18 is a vacuum environment formed by the connection of the cap layer 17 and the substrate layer 19;

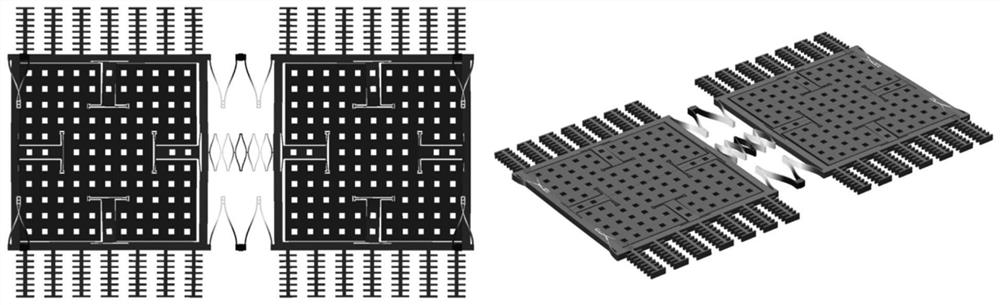

[0033] The frequency difference between the anti-phase driving mode and the in-phase driving mode is determined by the stiffness of the elastic coupling beam 14. By adjusting the elasticity

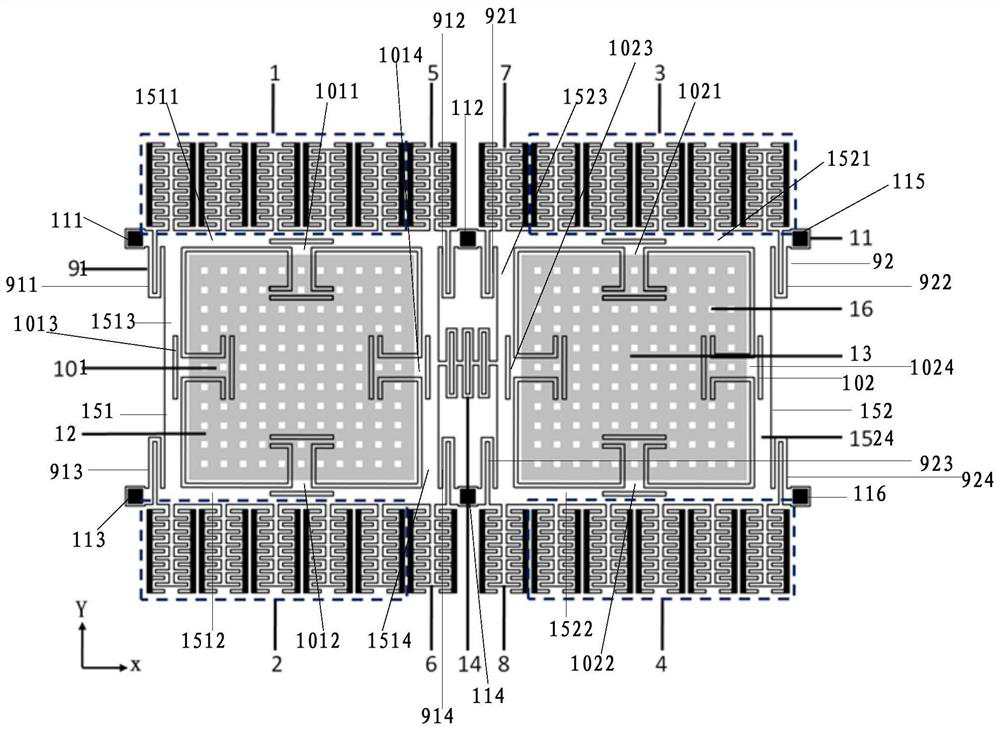

[0037] As shown in FIG. 1, the first drive elastic beam group 91 includes a first one drive elastic beam 911, a first two drive elastic beams

[0038] As shown in FIG. 1, the second drive elastic beam group 92 includes a second-first drive elastic beam 921, a second-second drive elastic beam

[0039] As shown in FIG. 1, the first detection elastic beam group 101 includes a first-detection elastic beam 1011, a first-second detection elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com