A new type of paint storage roller brush with continuous paint output

A technology for roller brushing and paint storage, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as low efficiency of painting operations, the inability of the roller to stand on its own, and the paint splashing around, preventing paint from flowing back and splashing. It can solve the effect of paint backflow and splashing, and reduce the consumption of manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

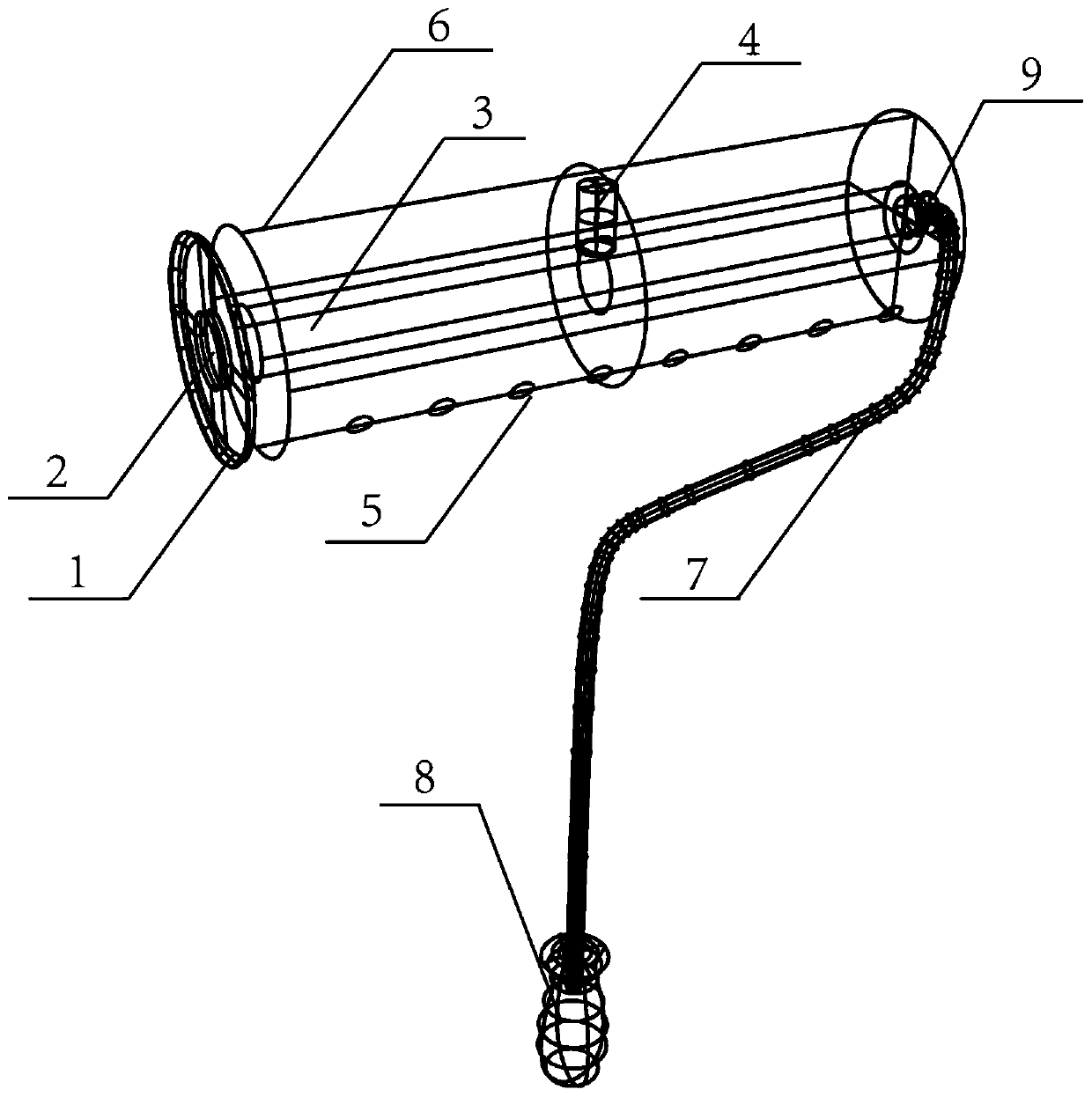

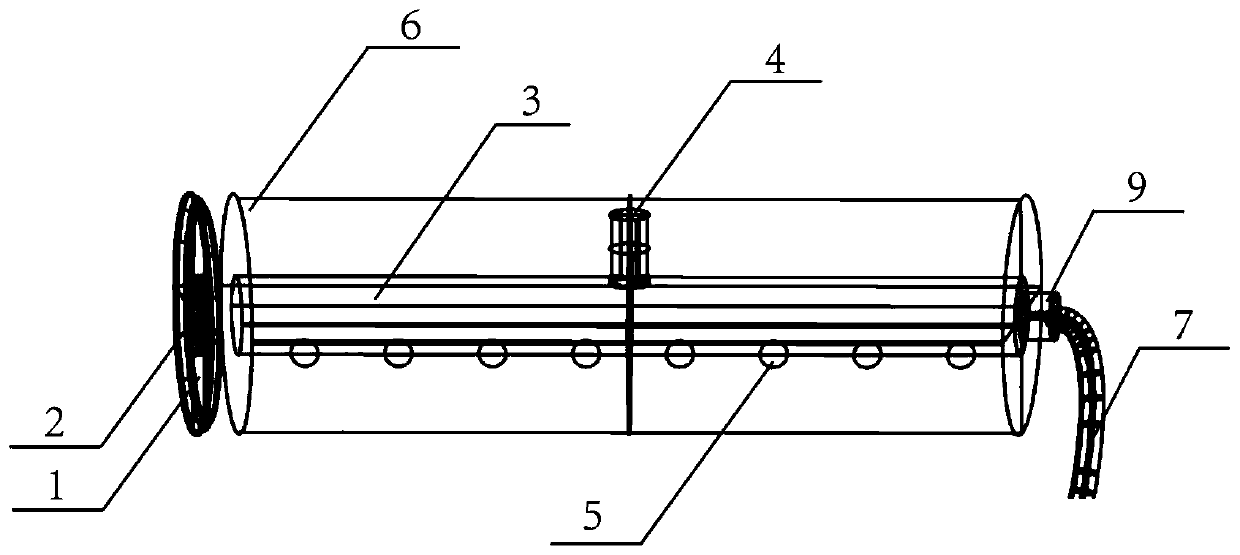

[0018] A new type of paint storage roller brush that continuously produces paint, including a roller cover 1, a connecting support rod 7, a rotating and fixing device 9, an outer coating layer, a horizontal core 3, a vertical core 4, and a paint storage roller 6. The outsourcing coating layer is arranged outside the paint storage cylinder 6, the vertical cylinder core 4 and the horizontal cylinder core 3 are arranged in the paint storage cylinder 6, and there is a paint inlet through hole 2 in the middle of the roller cover 1, and the paint inlet The through hole 2 communicates with the horizontal cylinder core 3, and the horizontal cylinder core 3 communicates with the vertical cylinder core 4, and the vertical cylinder core 4 is also connected with the paint storage cylinder 6. After the hole 5 flows out, it is painted on the outer coating layer, and the connecting support rod 7 is rotatably connected to the paint storage roller 6 through a rotating fixture 9 .

[0019] Furt...

Embodiment 2

[0027] Such as figure 1 , figure 2 In the illustrated embodiment, a novel paint storage roller brush of the present invention that continues to discharge paint consists of a roller cover 1, a paint inlet through hole 2, a horizontal cylinder core 3, a vertical cylinder core 4, a paint outlet through hole 5, a storage A paint roller 6, a connecting support rod 7, a handle 8, and a rotating fixture 9 are formed.

[0028] There is a paint inlet through hole 2 in the middle of the roller cover 1. When the paint has not passed through the paint inlet through hole 2, the paint will enter from the paint inlet through hole 2 and flow into the horizontal cylinder core 3, and the paint will be drawn through the vertical cylinder core 4. Introduce in the paint storage cylinder 6, and flow out from the paint discharge through hole 5 on the paint storage cylinder 6, the vertical core 4 is also vertically downward, and vertically upward when the user performs the painting operation.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com