Pin shearing and bending structure

A pin and bending table technology, applied in the field of bending structure, can solve the problems of wasting manpower and time, and the cutting size and bending angle cannot be guaranteed, so as to achieve the guarantee of cutting size and bending angle, reduce manpower and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

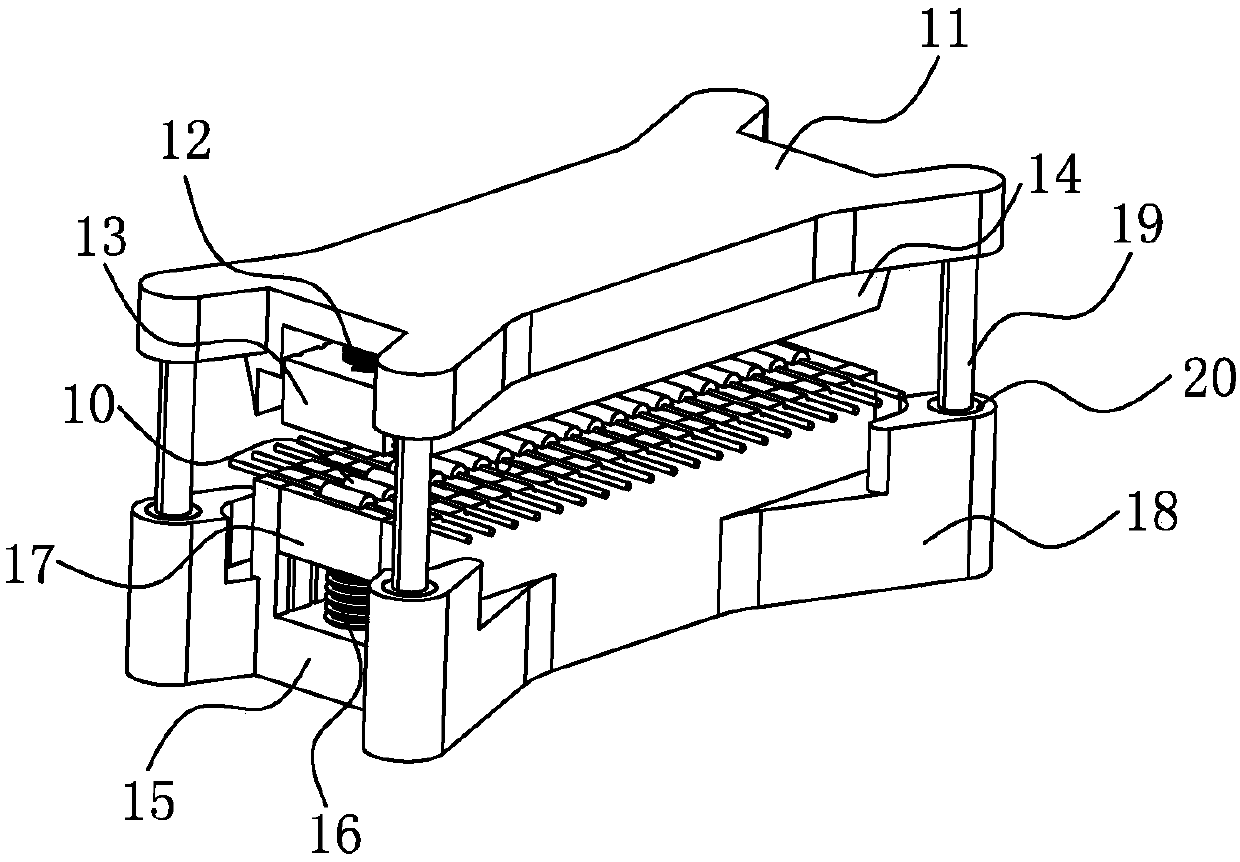

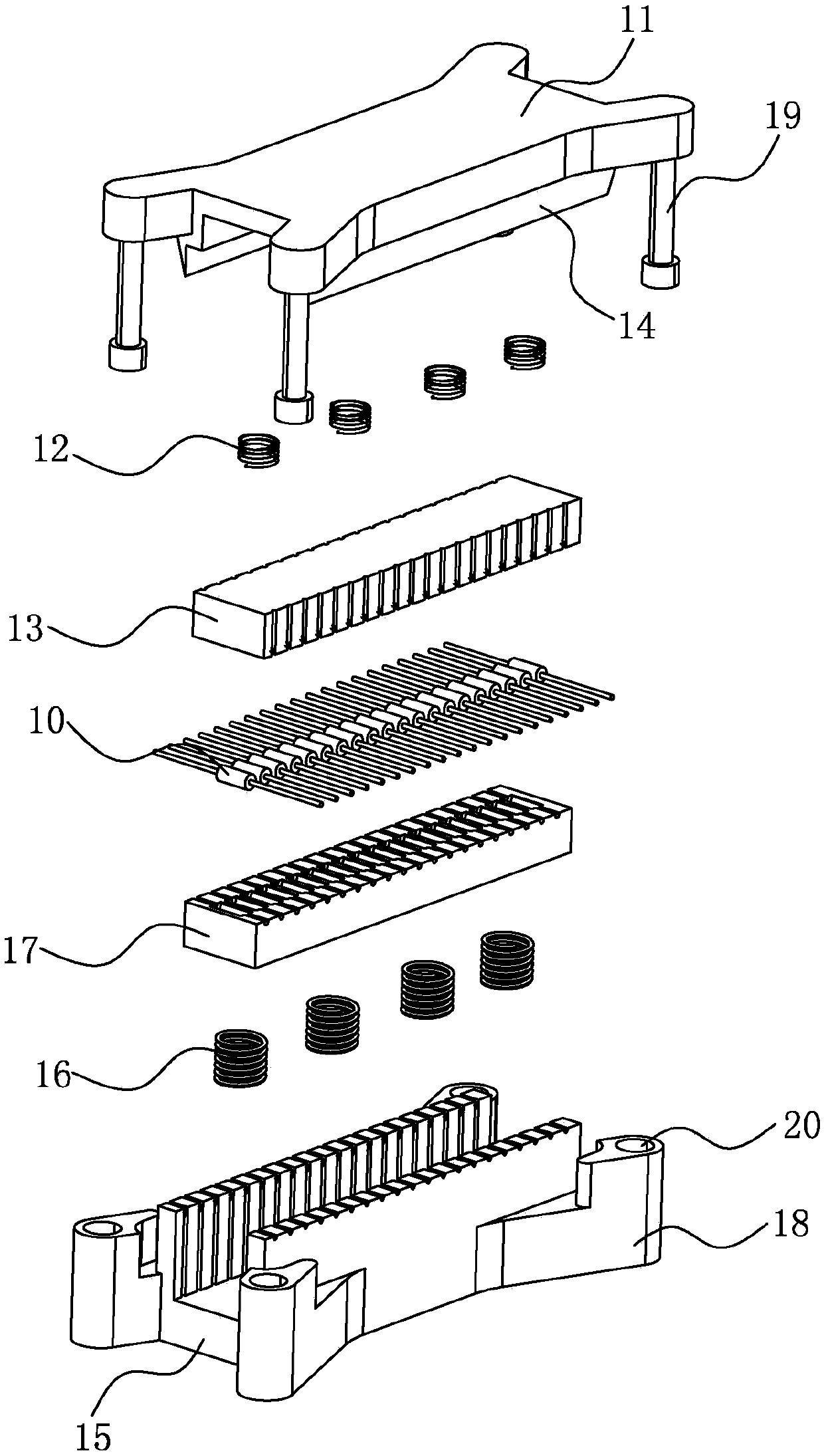

[0021] Please refer to figure 2 , image 3 , figure 2 Illustrated as a schematic diagram of the pin shearing and bending structure of the present invention, image 3 shown as figure 2 Schematic diagram of the breakdown structure.

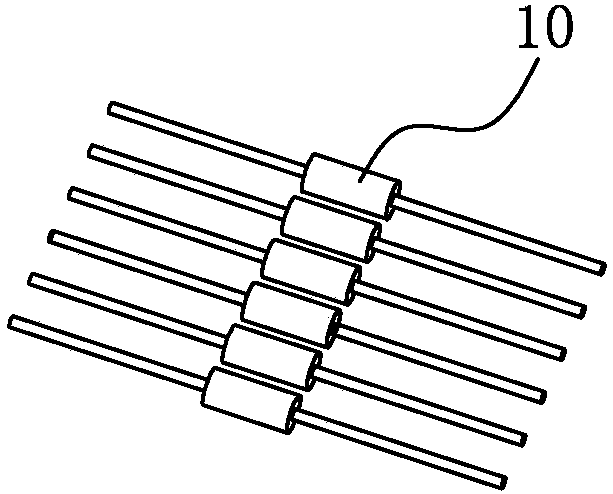

[0022] In order to achieve the above object, the pin shear bending structure of the present invention (for figure 1 Incoming pin 10 for processing), including:

[0023] Upper seat 11, the bottom surface of which is fixedly provided with a first spring 12 (the cushioning of the first spring 12 can better clamp and fix the pair of pins 10), and the lower end of the first spring 12 is fixedly provided with an upper Slider 13, the bottom surface of the upper slider 13 has a first positioning surface, the bottom surface of the upper seat 11 is also extended with a cutter 14, and the cutter 14 extends close to the side of the upper slider 13;

[0024] The lower seat 15 is fixedly provided with a second spring 16 on its top surface, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com