Convenient support pipe conveying device for construction site

A technology for construction sites, handling devices, applied in the direction of transportation and packaging, multi-axis trolleys, trolley accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

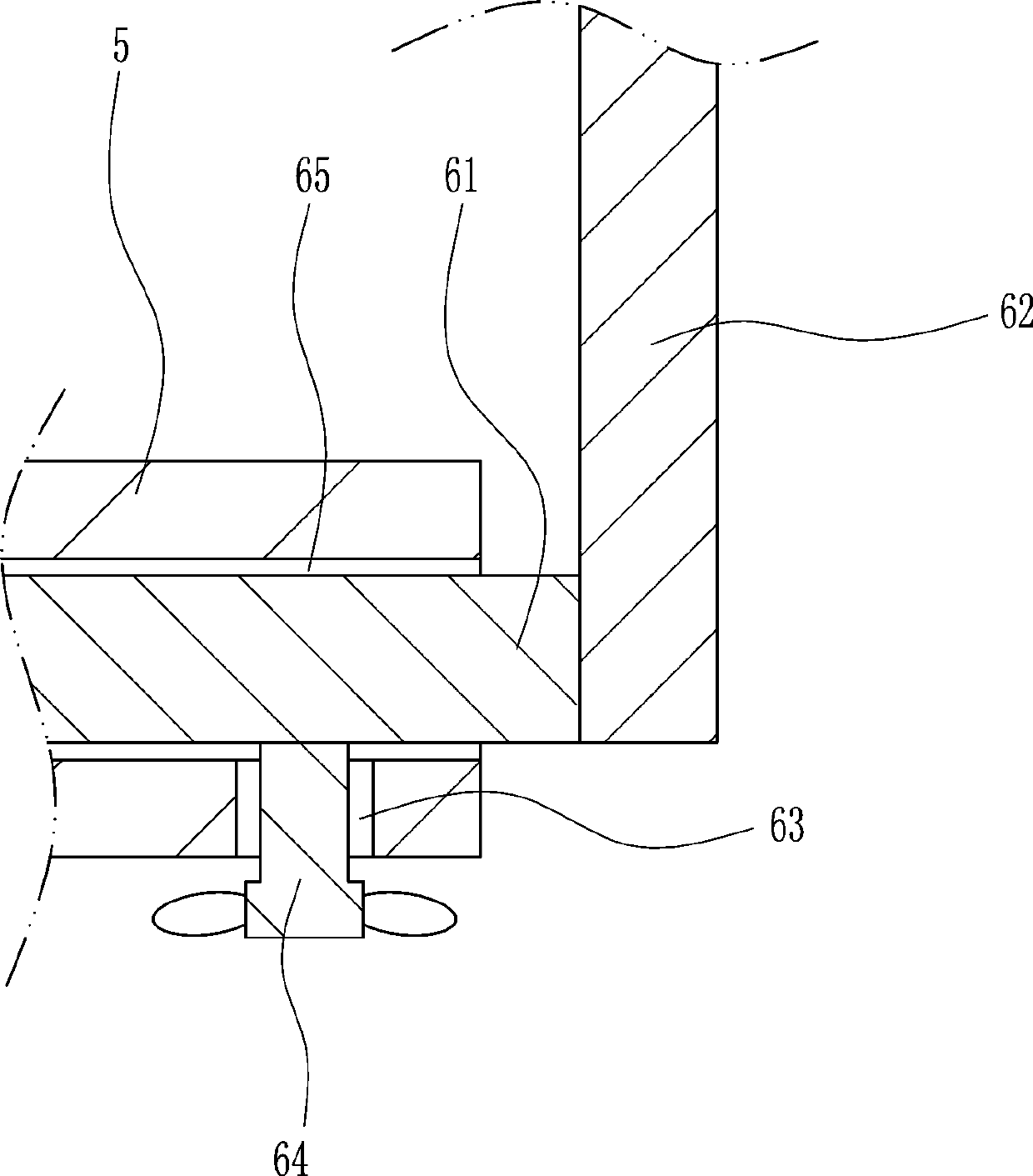

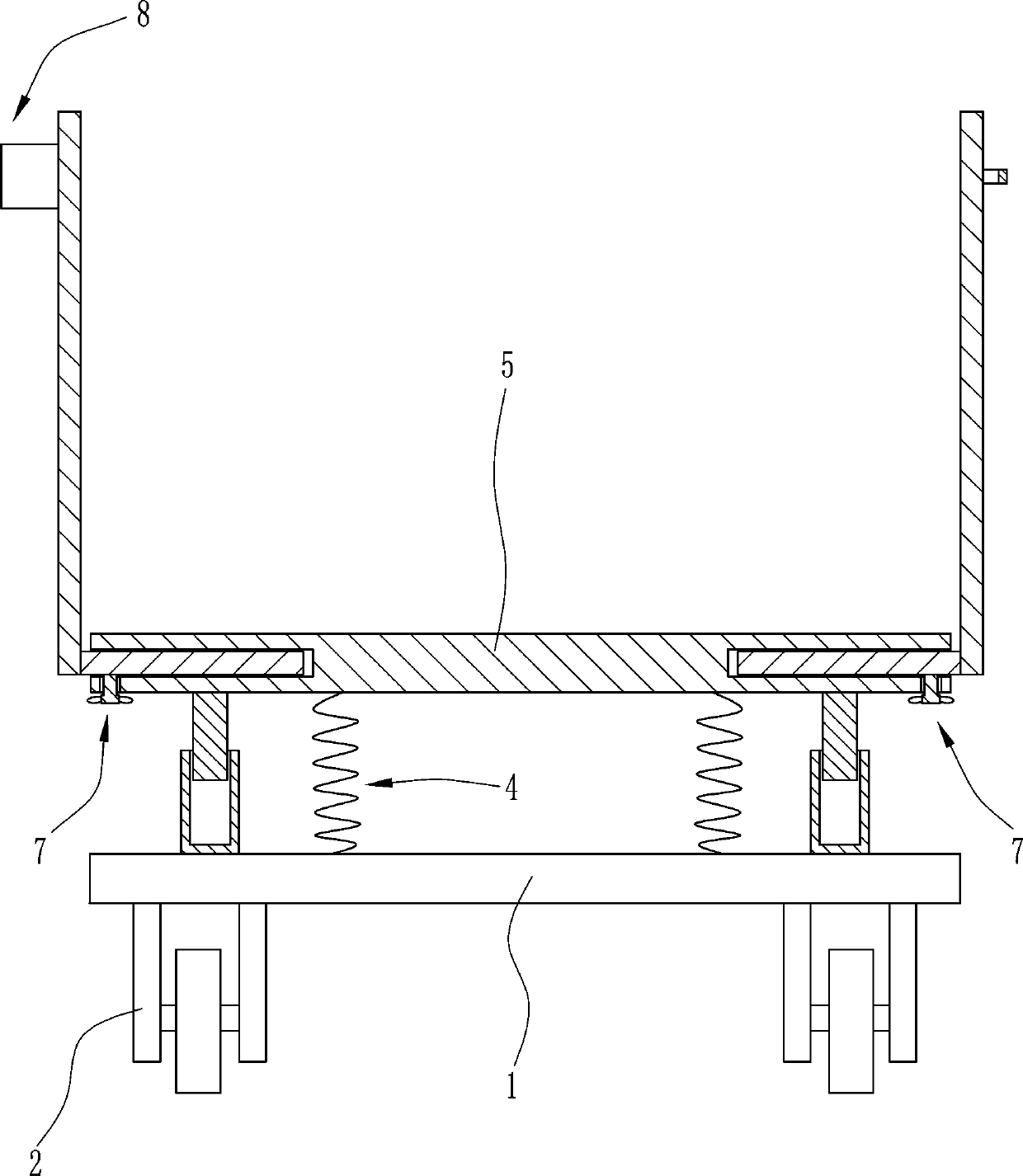

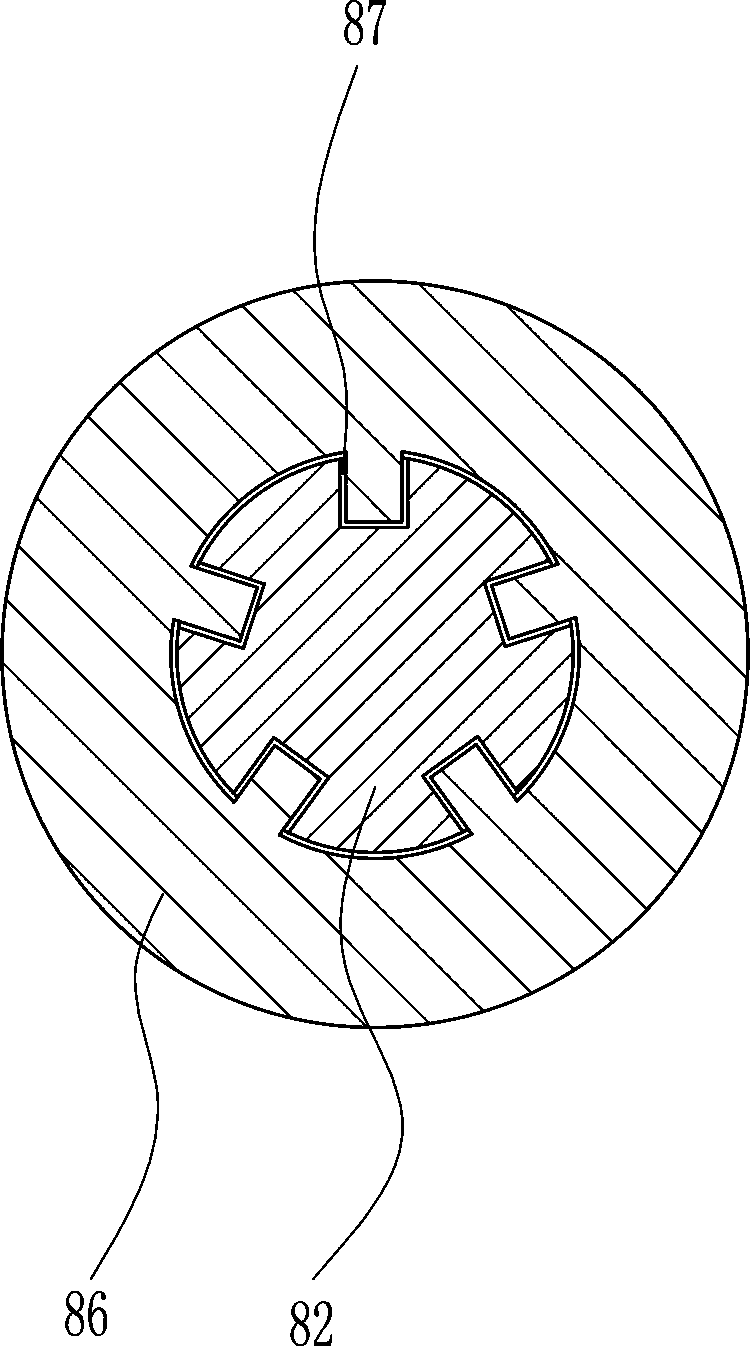

[0038] A portable bracket pipe handling device for a construction site, such as Figure 1-10 As shown, it includes base plate 1, wheel 2, push handle 3, shock absorbing mechanism 4, L-shaped plate 5, length adjustment mechanism 6, width adjustment mechanism 7 and binding mechanism 8; wheel 2 is fixedly connected to the bottom of base plate 1; push handle 3 is fixed Connected to one end of the bottom plate 1, the shock absorbing mechanism 4 is fixed to the other end of the bottom plate 1; the L-shaped plate 5 is fixed to the output end of the shock absorbing mechanism 4, and the length adjustment mechanism 6 is installed on the end of the bottom of the L-shaped plate 5 away from the push handle 3 , the two width adjustment mechanisms 7 are affixed to the front and rear ends of the bottom of the L-shaped plate 5, and the binding mechanism 8 is affixed to the output end of the width adjustment mechanism 7;

[0039] The damping mechanism 4 includes a hollow rod 41, an insertion ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com