Lighting modules for vehicle headlights

A technology of light-emitting modules and headlights, which is applied in the direction of headlights, road vehicles, vehicle parts, etc., and can solve problems such as non-directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following embodiments, the same reference numerals denote the same features unless otherwise stated.

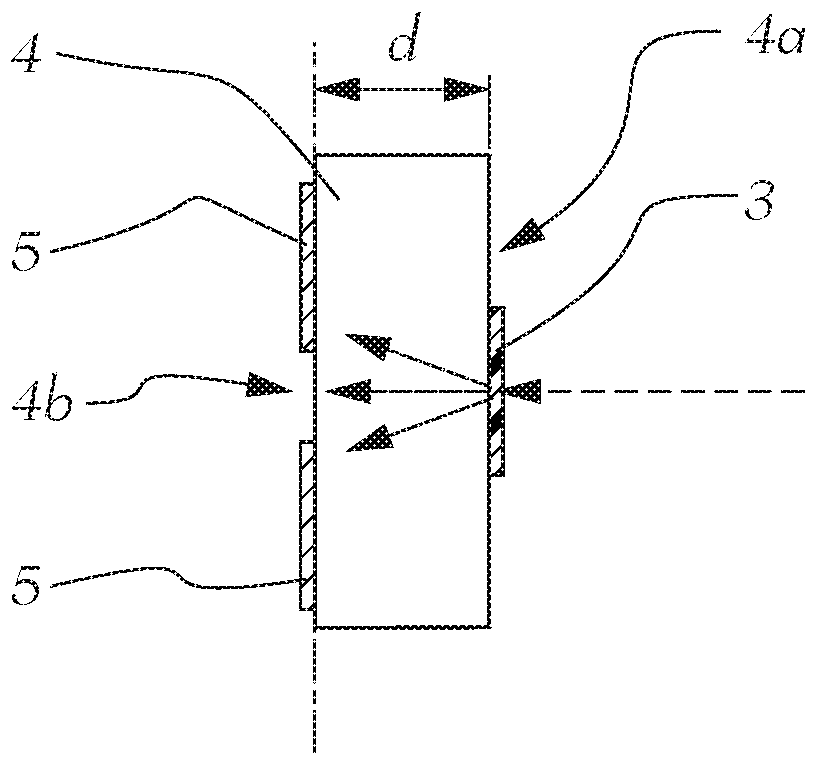

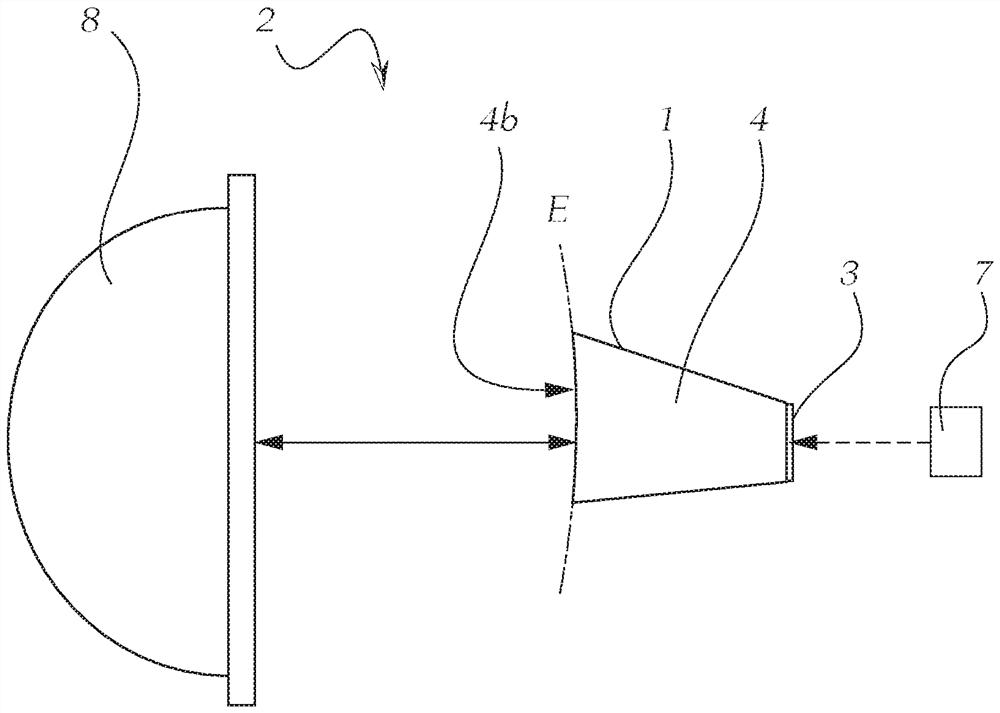

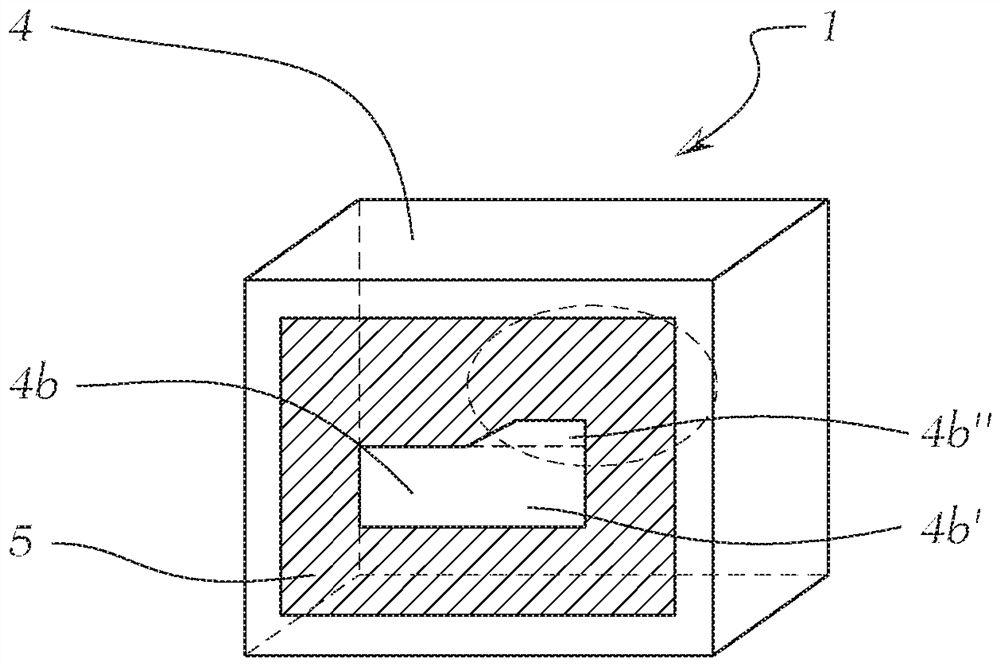

[0024] figure 1 A front view of a first embodiment of a lighting module 1 according to the invention is shown. where it can be identified that the Figure 6 The light-emitting module 1 of the vehicle headlight 2 shown in , wherein the light-emitting module 1 has at least one light-emitting element 3 that can be excited by irradiation with laser light to radiate visible light. The light-emitting element 3 is arranged on the light-transmissible carrier element 4 in the figure 2 At the rear side shown in , a light entry surface 4 a is formed there, wherein the light emitting element 3 injects light into the carrier element 4 via the light entry surface 4 a. Carrier element 4 in the figure 1 The front side shown in the figure has a light exit surface 4 b lying opposite the light entry surface 4 a , which in the exemplary embodiment shown is surrounded by a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com