Steel band winding and packing machine

A steel belt and winding device technology, applied in the field of steel belt winding balers, can solve the problems affecting the personal safety of operators, affecting the working efficiency of winding steel belt, affecting the stability and safety of steel belt, etc., to improve work efficiency, The effect of reducing manual output and increasing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

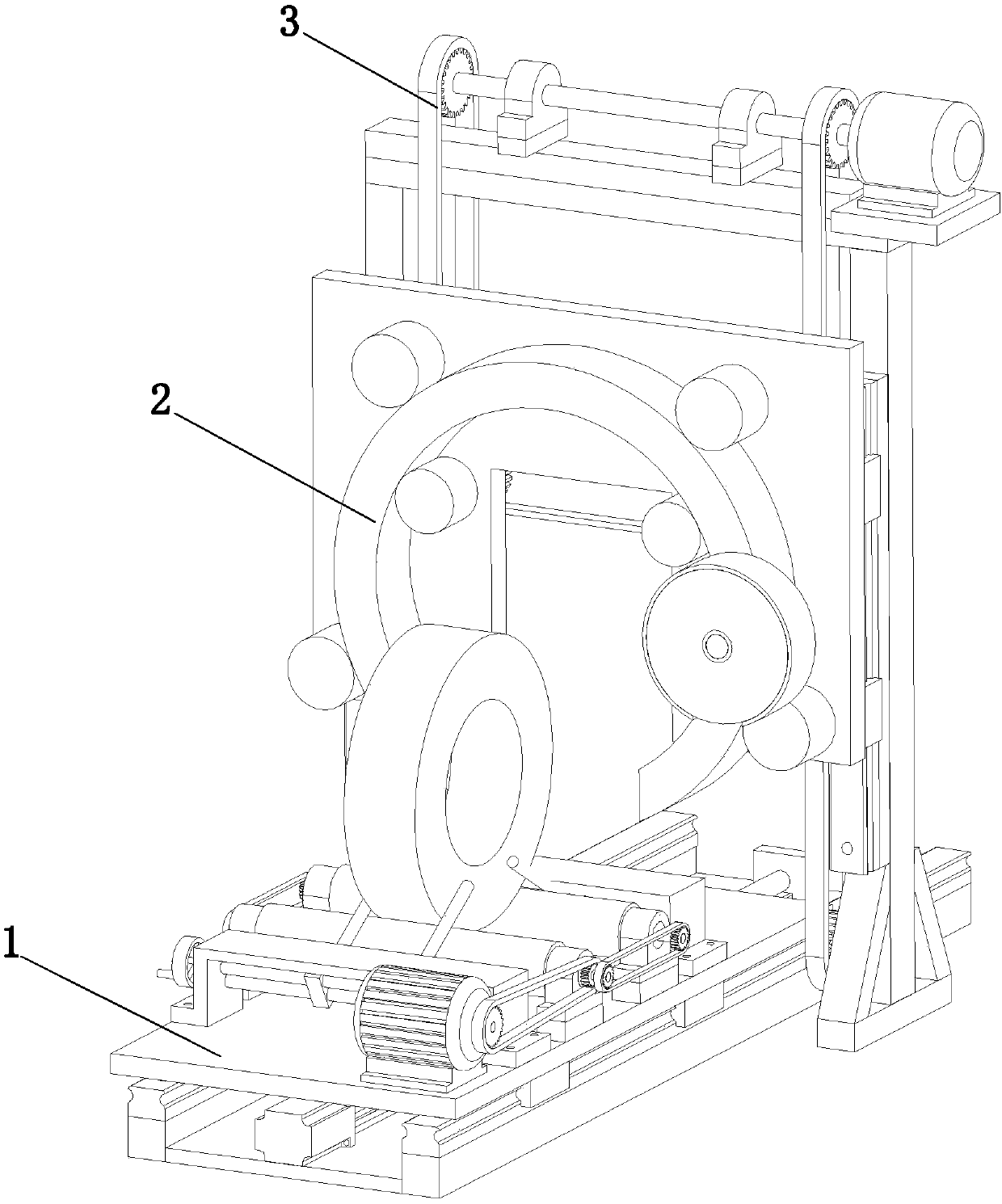

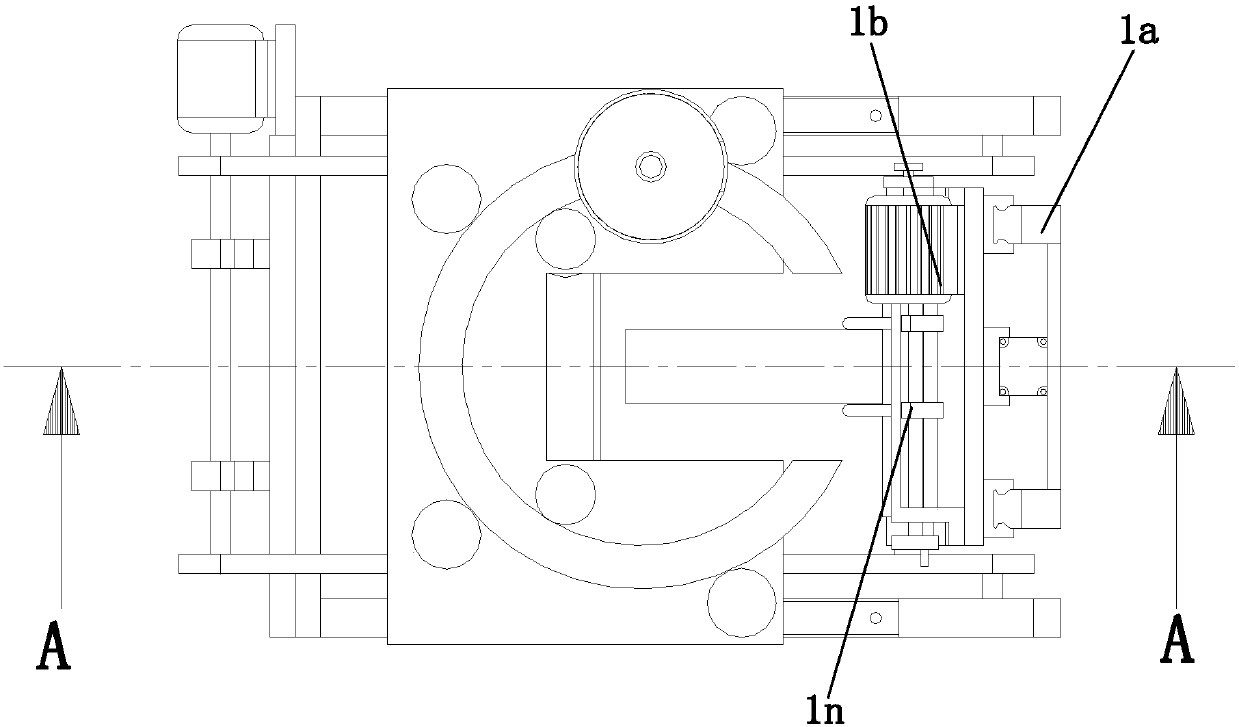

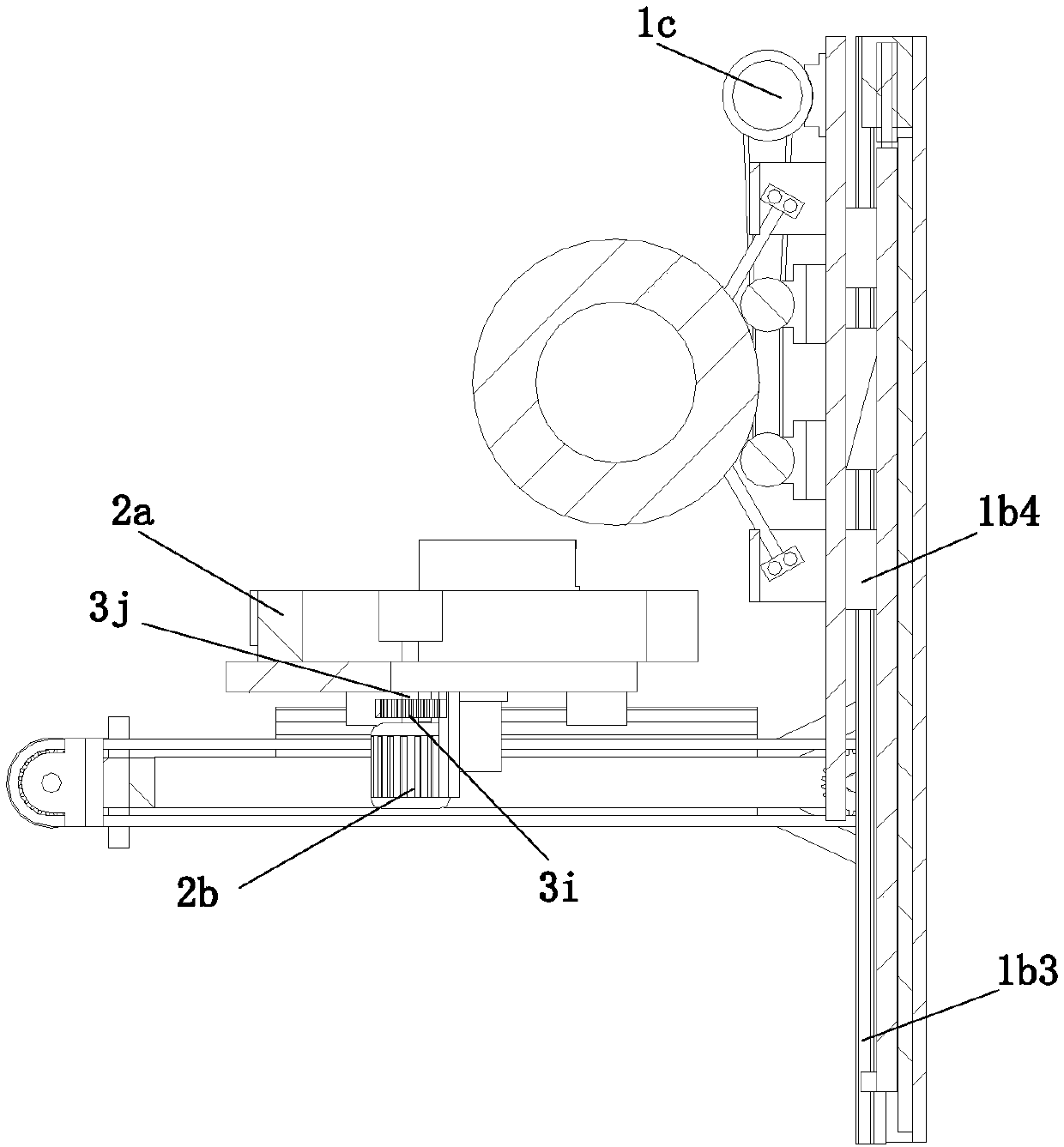

[0030] refer to Figure 1 to Figure 11A steel belt winding baler shown includes a steel belt conveying device 1, a steel belt winding device 2 and a winding driving device 3 for driving the steel belt winding device 2, and the steel belt winding device 2 is located at the steel belt conveying Above the device 1, the steel strip conveying device 1 includes a carrying platform 1a, a platform driving part 1b for driving the carrying platform 1a to move directly below the steel strip winding device 2, and is installed on the top of the carrying platform 1a for driving The steel belt driving part 1c for steel belt movement, the winding drive device 3 includes a mounting frame 3a and a transmission part 3b for driving the steel belt winding device 2 to move up and down, and the steel tape winding device 2 is movably insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com