NACA fin type adjustable swirler for solid-fuel ramjet connection experiment

A technology of ramjet and solid fuel, which is applied in the direction of engine testing, machine/structural component testing, instruments, etc. It can solve the problems of non-adjustable swirl number and large total pressure loss of swirler, etc. Achieve the effect of reducing total pressure loss, small total pressure loss and reducing aerodynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

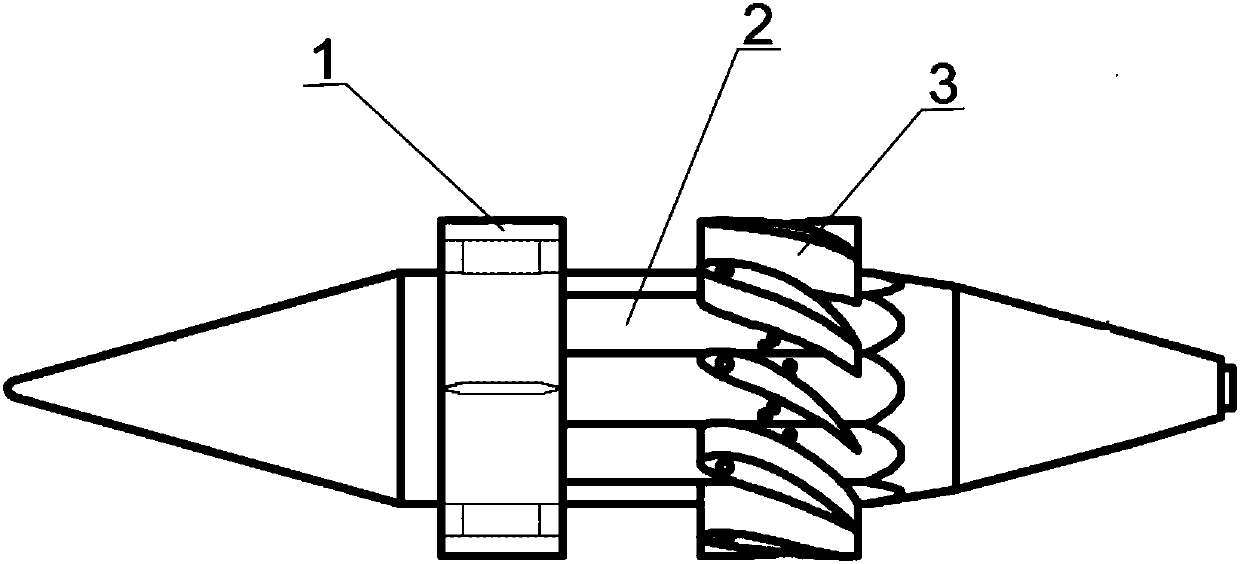

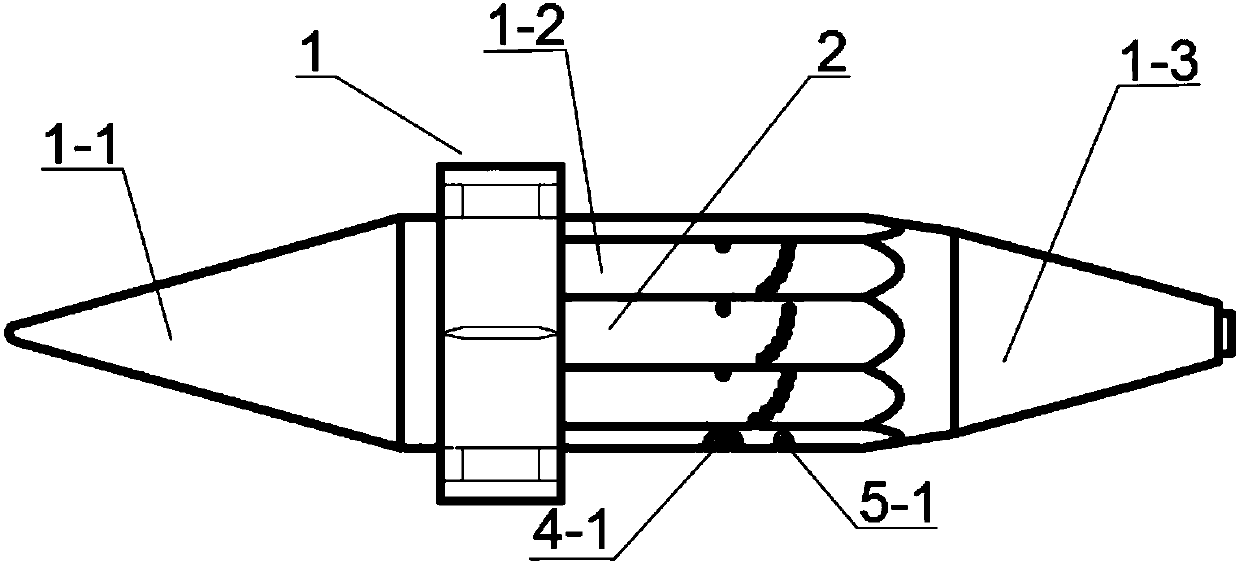

[0023] combine Figure 1 to Figure 3 , a NACA vane type adjustable swirler for solid fuel ramjet tube-to-tube experiments, comprising a solid fuel ramjet central cone 1 and NACA fins 3, the solid fuel ramjet central cone 1 includes sequentially connected Conical section 1-1, cylindrical section 1-2 and converging section 1-3, assuming that the length of cylindrical section 1-2 is L, 10 NACA fin fixing planes 2 are successively and continuously distributed on the outer wall of said cylindrical section 1-2, The NACA fin fixing plane 2 is parallel to the central axis of the central cone 1 of the solid fuel ramjet, and ten NACA fins 3 are respectively fixed on the NACA fin fixing plane 2 .

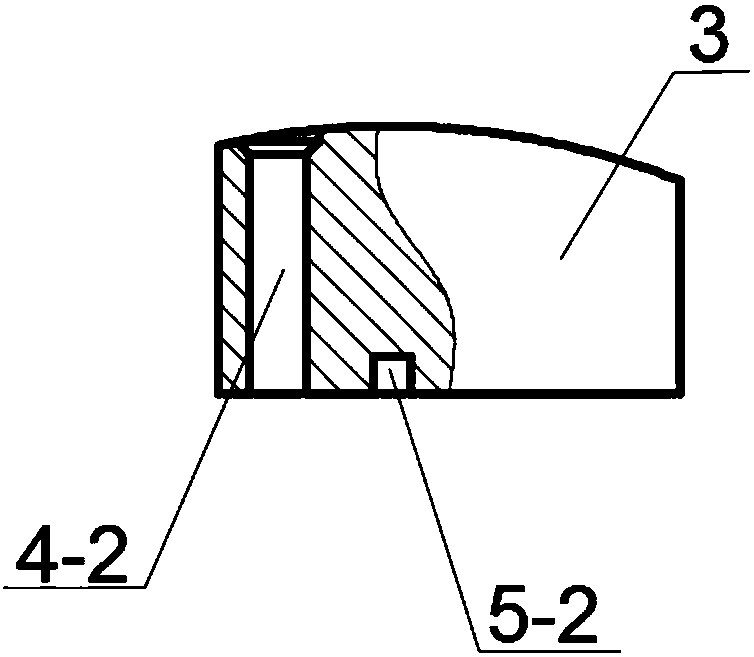

[0024] The NACA fin fixing plane 2 is provided with a threaded hole 4-1 and 6 positioning pin holes 5-1, and the distance between the threaded hole 4-1 and the junction of the conical section 1-1 and the cylindrical section 1-2 is 1 / 2L, the 6 positioning pin holes 5-1 take the threaded hole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com