A calibration method for LED display based on reference objects

A technology of LED display screen and calibration method, which is applied to static indicators, instruments, etc., can solve the problems of destroying the display effect, inability to achieve seamless splicing, and non-transmissive optical characteristics, and achieve the effect of improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

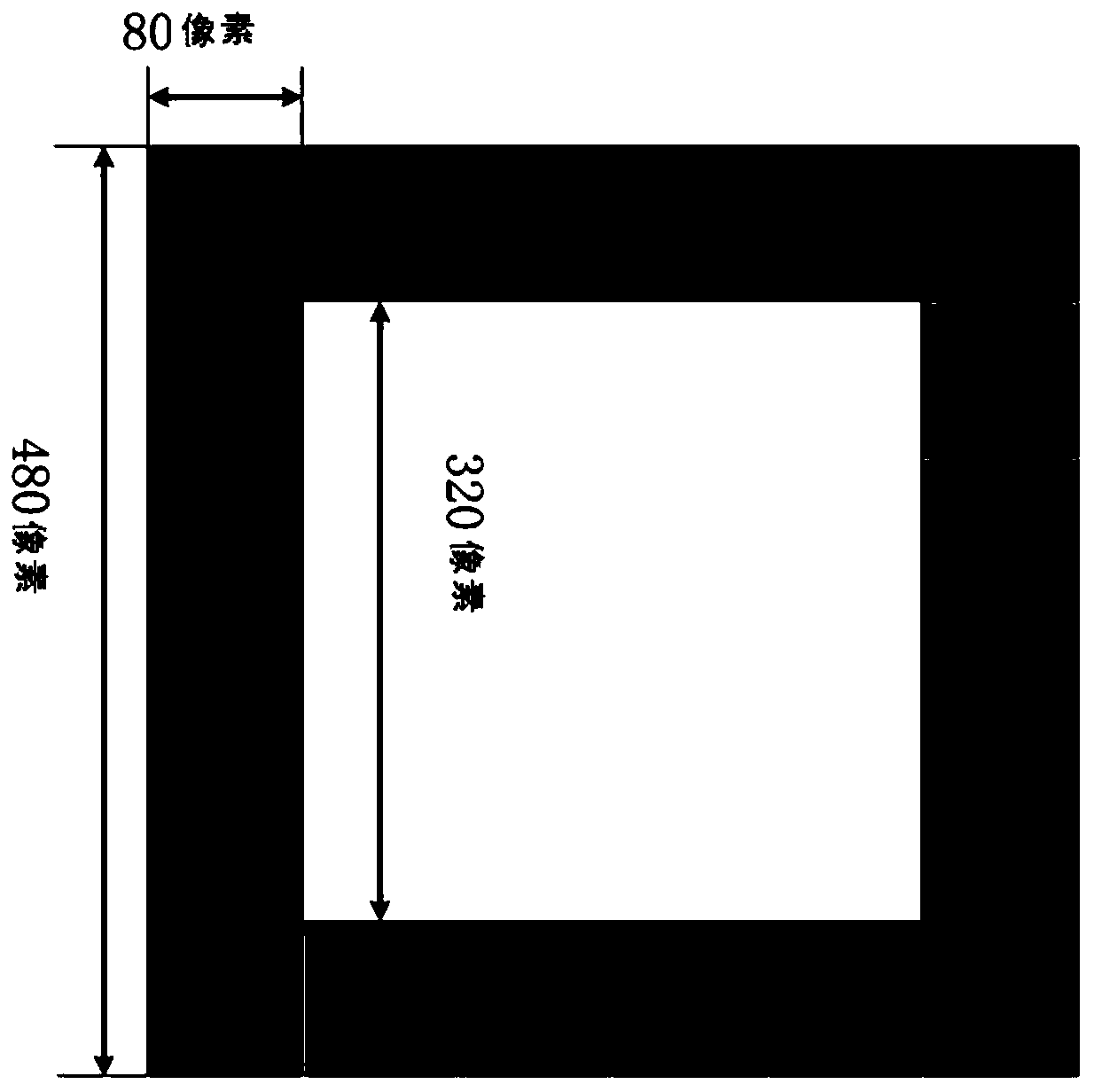

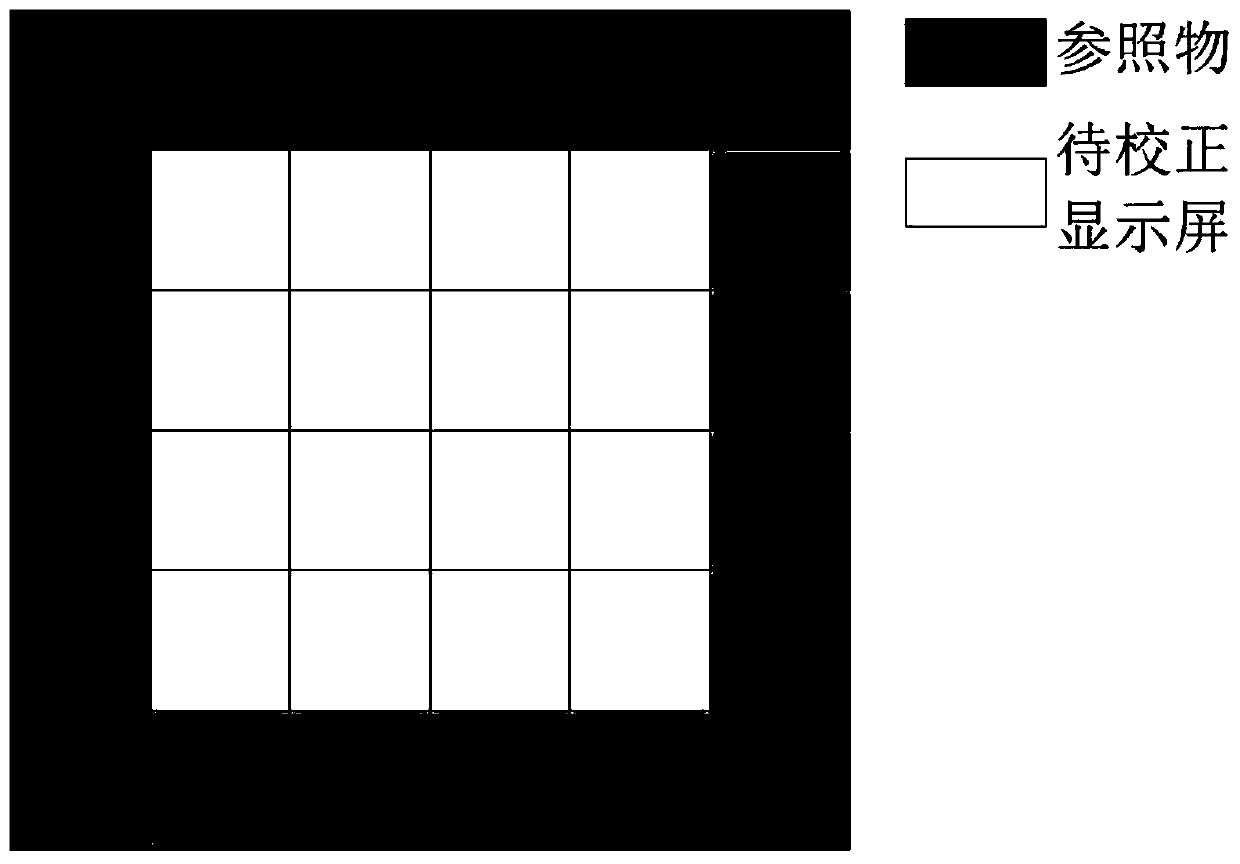

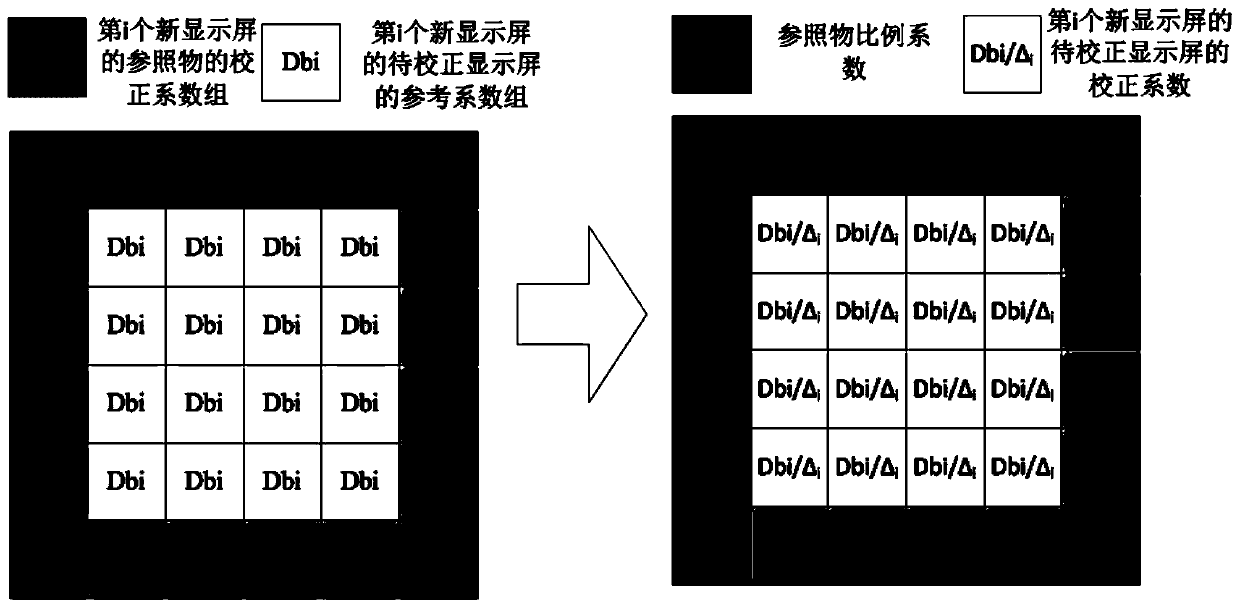

[0050] The reference object may be a plurality of pixels.

[0051] The reference object may be a display module or a display box; the display module or the display box is arranged on one side of the display screen to be corrected to form a new display screen with the display screen to be corrected.

[0052] The reference objects are multiple display modules or multiple display cabinets; multiple display modules or multiple display cabinets are arranged on one side of the display screen to be corrected to form a new display screen with the display screen to be corrected.

[0053] The reference object is a plurality of display modules or a plurality of display cabinets; a plurality of display modules or a plurality of display cabinets are arranged on two sides or three sides of the display screen to be corrected to form a new display with the display screen to be corrected Screen.

[0054] The reference objects are multiple display modules or multiple display cabinets; multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com