Construction method of large-caliber underwater cast-in-place pile for power transmission tower foundation

A technology for underwater grouting and power transmission towers, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of failure to meet the design requirements of friction piles, construction difficulties, pile necking, etc., and achieve obvious construction speed , does not affect the construction progress, and improves the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

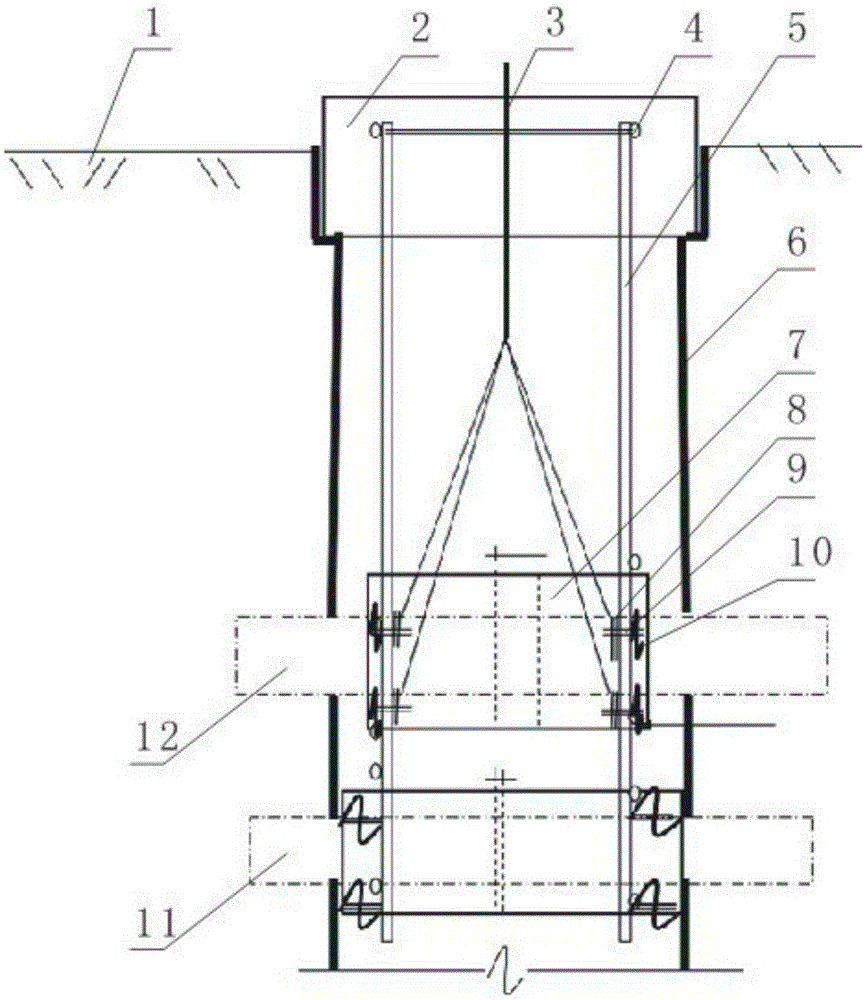

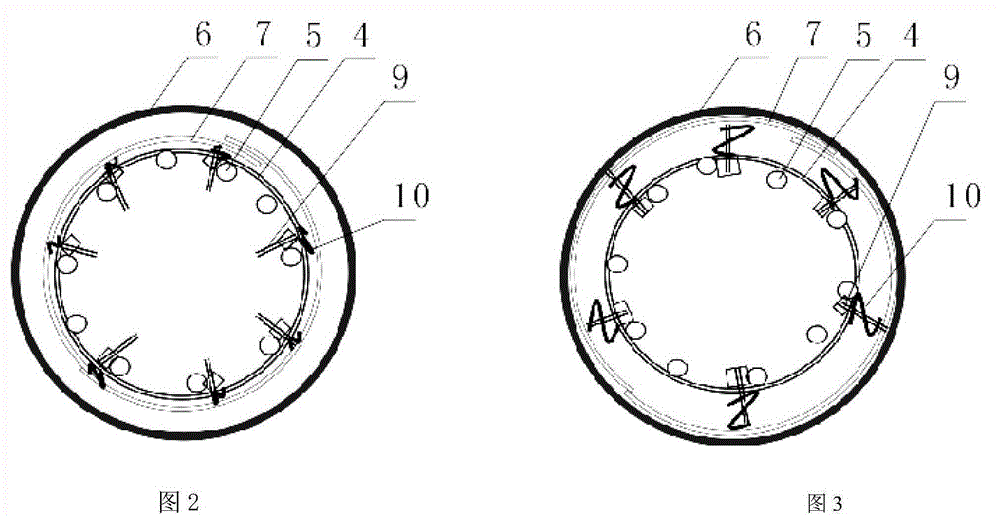

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0025] A method for constructing large-diameter underwater cast-in-place piles for the foundation of a power transmission tower. When the mud retaining wall is formed into holes for filling piles, the mud retaining wall 6 is initially constructed. The inside of the mud retaining wall is a pile hole, which is installed coaxially at the ground 1 position at the top of the pile hole. Wellhead casing 2, the top of the wellhead casing is higher than the ground, and the innovation of the present invention is that the construction steps are as follows:

[0026] (1) Exploring the position of the quicksand layer, the distance between the ground 1 and the quicksand layer is obtained by geological survey, and ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com