Demister

The technology of a demister and a demister cylinder is applied in the field of demister, which can solve the problems of single structure and low demister efficiency, and achieve the effects of improving the demister efficiency, strengthening the effect of aerosol separation, and reducing consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

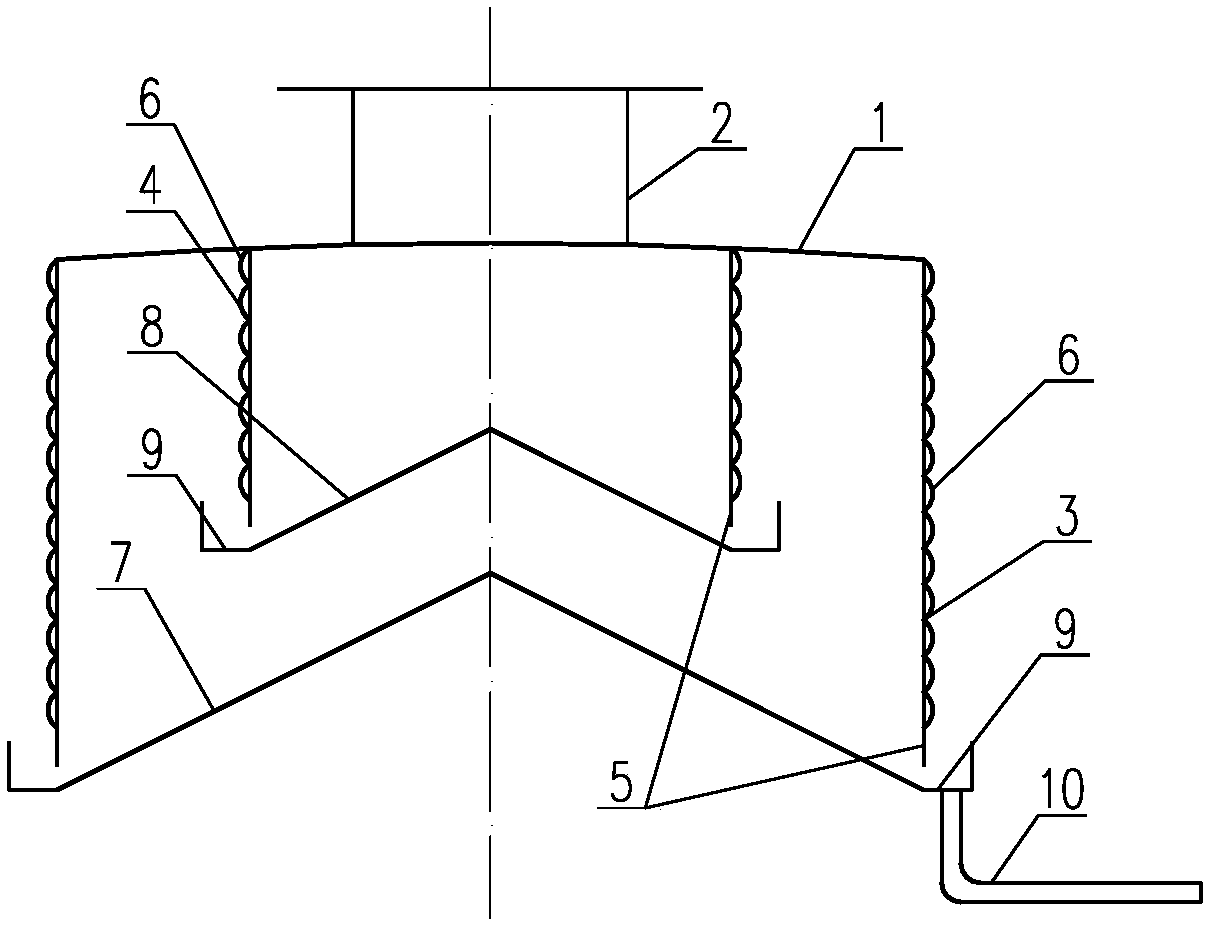

[0017] Such as figure 1 As shown, a demister of the present invention is arranged at the gas outlet 2 at the top of the tower body 1; includes a primary demister 3 and a secondary demister 4; the primary demister 3 consists of a primary The defoaming cylinder and the first-stage ring cone plate 7 are composed, and the secondary defoaming device 4 is composed of the secondary defoaming cylinder and the secondary ring cone plate 8; the secondary defoaming cylinder is arranged on the tower body 1 below the gas outlet 2 Inside, the secondary ring cone plate 8 is set under the secondary demister; There is a first-level ring cone plate 7 under the bottom of the ring; there is an annular gap between the first-level defoaming cylinder and the first-level ring cone plate 7, and between the second-level defoaming cylinder and the second-level ring cone pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com