A kind of polyolefin composition and polyolefin material

A technology of polyolefin and composition, which is applied in the field of polyolefin materials, can solve problems such as increased mold shrinkage anisotropy, poor processing performance of polypropylene, material molding and application limitations, etc., and achieves low mold shrinkage, Effect of high rigidity and shrinkage anisotropy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to one embodiment, the polyolefin component is produced by a process comprising the steps of:

[0036] 1) In the presence of an olefin polymerization catalyst, optionally in the presence of a molecular weight regulator, propylene, or propylene and ethylene and / or 1-butene are subjected to a first polymerization reaction to obtain a reactant stream containing component (a) ;

[0037] 2) In the presence of said reactant stream, optionally in the presence of a molecular weight regulator, ethylene and 1-butene are subjected to a second polymerization reaction to obtain the compound containing component (b) and component (a). the polyolefin components.

[0038] In the present invention, the molecular weight regulator is preferably hydrogen.

[0039] The olefin polymerization catalyst may be selected from Ziegler-Natta catalysts. The Ziegler-Natta catalyst may contain: an active solid catalyst component, an organoaluminum compound and an optional external electro...

Embodiment 1

[0087] This example serves to illustrate the polyolefin composition and polyolefin material of the present invention.

[0088] The titanium-containing active solid catalyst component (main catalyst) is prepared by the method described in Example 1 of CN93102795.0, its Ti content: 2.2% by weight, di-n-butyl phthalate (DIBP) content: 11.2% by weight.

[0089] The polymerization reaction was carried out on a polypropylene pilot plant.

[0090] Polymerization method and steps are as follows:

[0091] Pre-polymerization: After the main catalyst, co-catalyst (triethylaluminum (TEA)), external electron donor compound (methylcyclohexyldimethoxysilane (CHMMS)) was pre-contacted at 10°C for 20 minutes, the pre-polymerization was continuously added The reactor was subjected to a prepolymerization reaction, wherein the flow rate of TEA was 6 g / hr, the flow rate of CHMMS was 1.02 g / hr, and the flow rate of the main catalyst was 0.36 g / hr. The pre-polymerization is carried out in the bulk...

Embodiment 2

[0098] This example serves to illustrate the polyolefin composition and polyolefin material of the present invention.

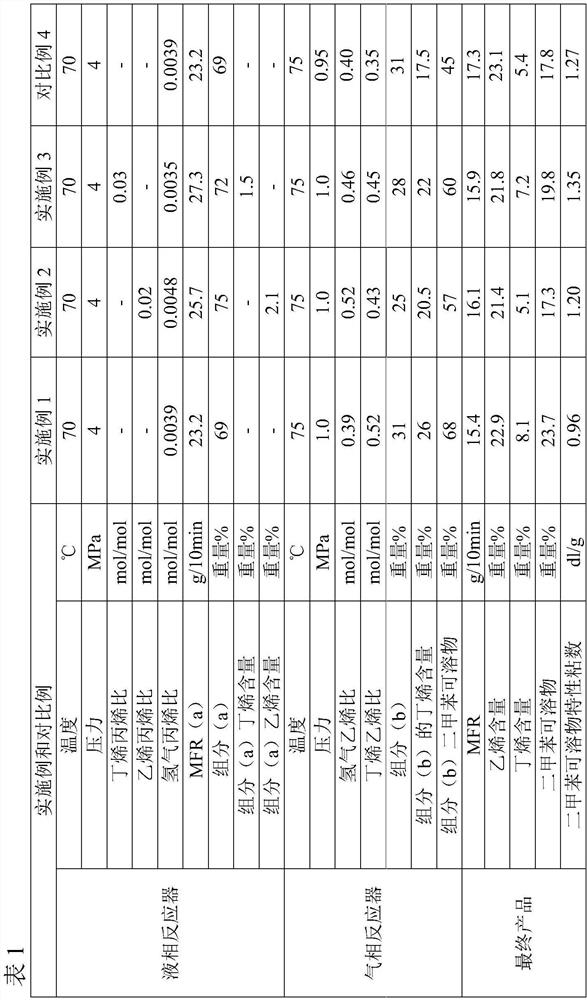

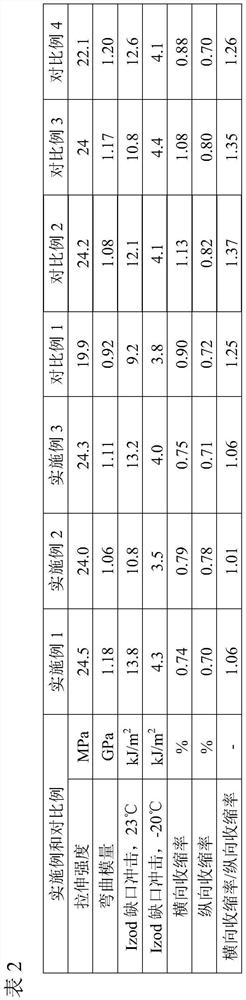

[0099] The polyolefin composition and polyolefin material are prepared according to the method of Example 1, the difference is: the copolymerization reaction of propylene and ethylene is completed in the loop reactor, the ethylene concentration detected by online chromatography is 2mol%, and the hydrogen concentration is 0.48 mol%. The specific process conditions and the composition of the polyolefin components are shown in Table 1, and the properties of the polyolefin materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com