Torsional spring automated twisting device

A torsion spring, automatic feeding technology, applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, can solve problems such as difficulty in adapting to the adjustment of technical parameters of torsion springs, inability to precisely control the torsion angle, and poor torsion quality. Achieve high production efficiency, achieve precise control, and improve product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

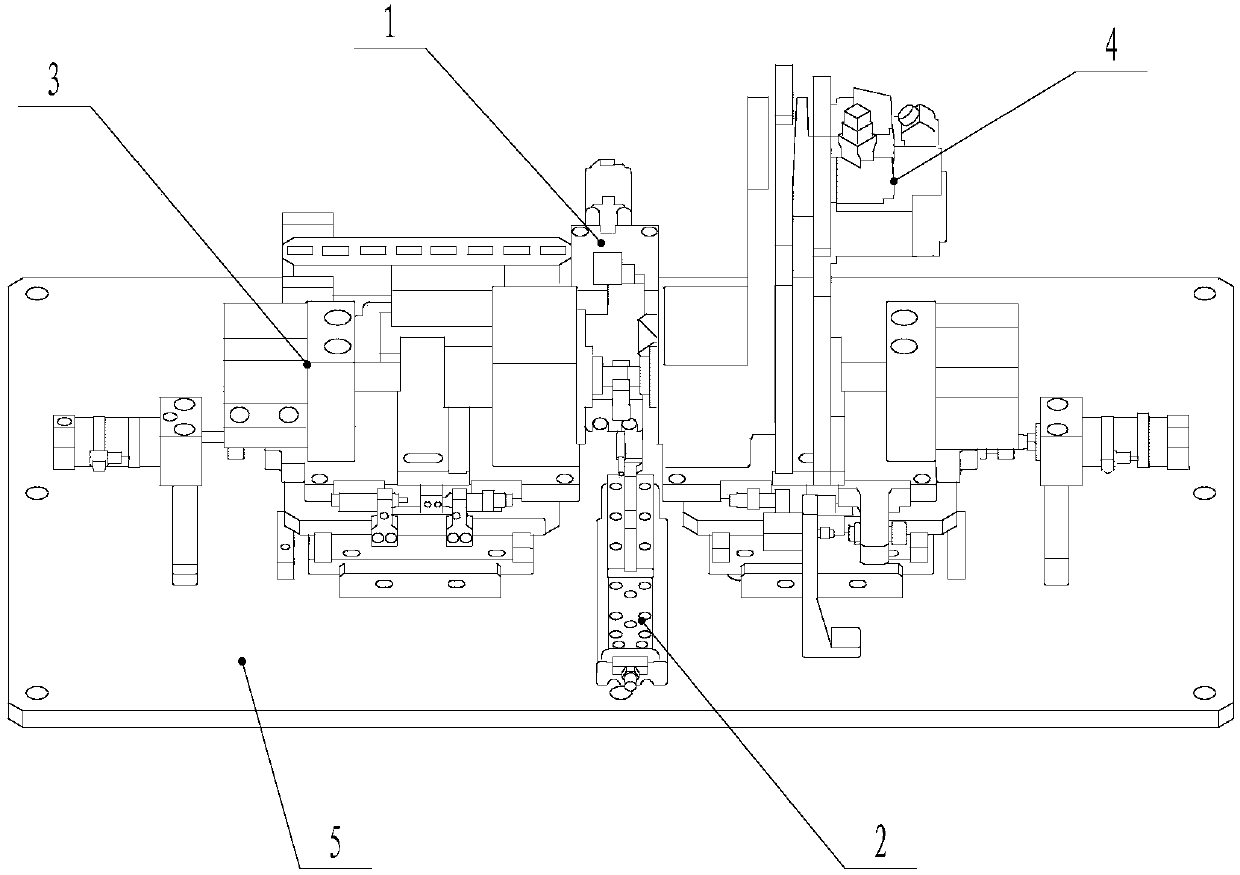

[0022] The torsion spring automatic twisting device includes a support 5, and also includes an automatic feeding mechanism 1, an automatic feeding mechanism 2, a compression cylinder mechanism 3 and a rotary motor mechanism 4 arranged on the support 5, and a compression cylinder mechanism 3 and the rotating motor mechanism 4 are arranged coaxially on both sides of the automatic feeding mechanism 2, the automatic feeding mechanism 1 is provided with a direct vibration module 109, the automatic feeding mechanism 2 is provided with a feeding pneumatic slide table 201, the direct vibration module 109 and the feeding The pneumatic slide table 201 is placed vertically.

Embodiment 2

[0024] The torsion spring automatic twisting device includes a support 5, and also includes an automatic feeding mechanism 1, an automatic feeding mechanism 2, a compression cylinder mechanism 3 and a rotary motor mechanism 4 arranged on the support 5, and a compression cylinder mechanism 3 and the rotating motor mechanism 4 are arranged coaxially on both sides of the automatic feeding mechanism 2, the automatic feeding mechanism 1 is provided with a direct vibration module 109, the automatic feeding mechanism 2 is provided with a feeding pneumatic slide table 201, the direct vibration module 109 and the feeding The pneumatic slide table 201 is placed vertically.

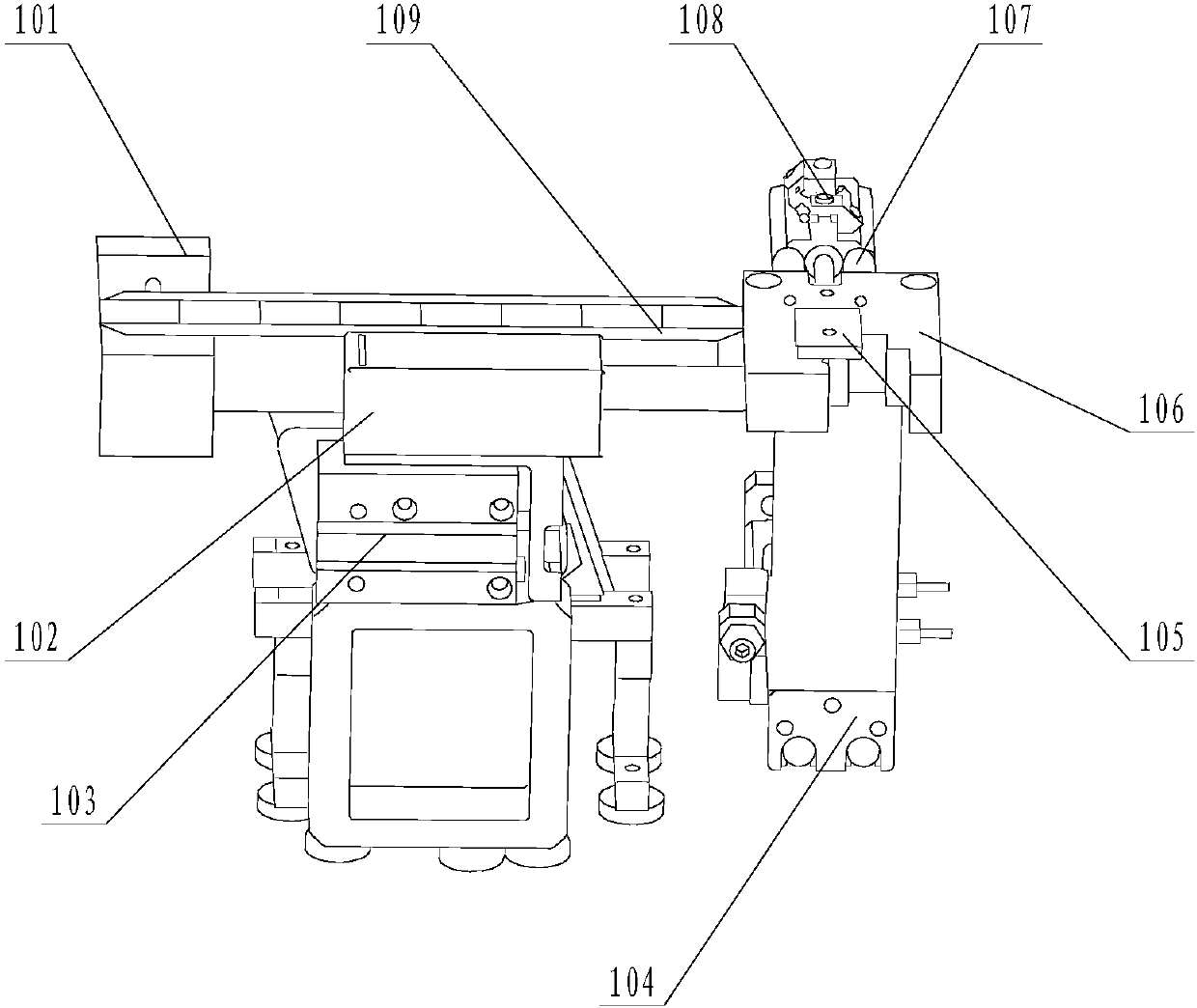

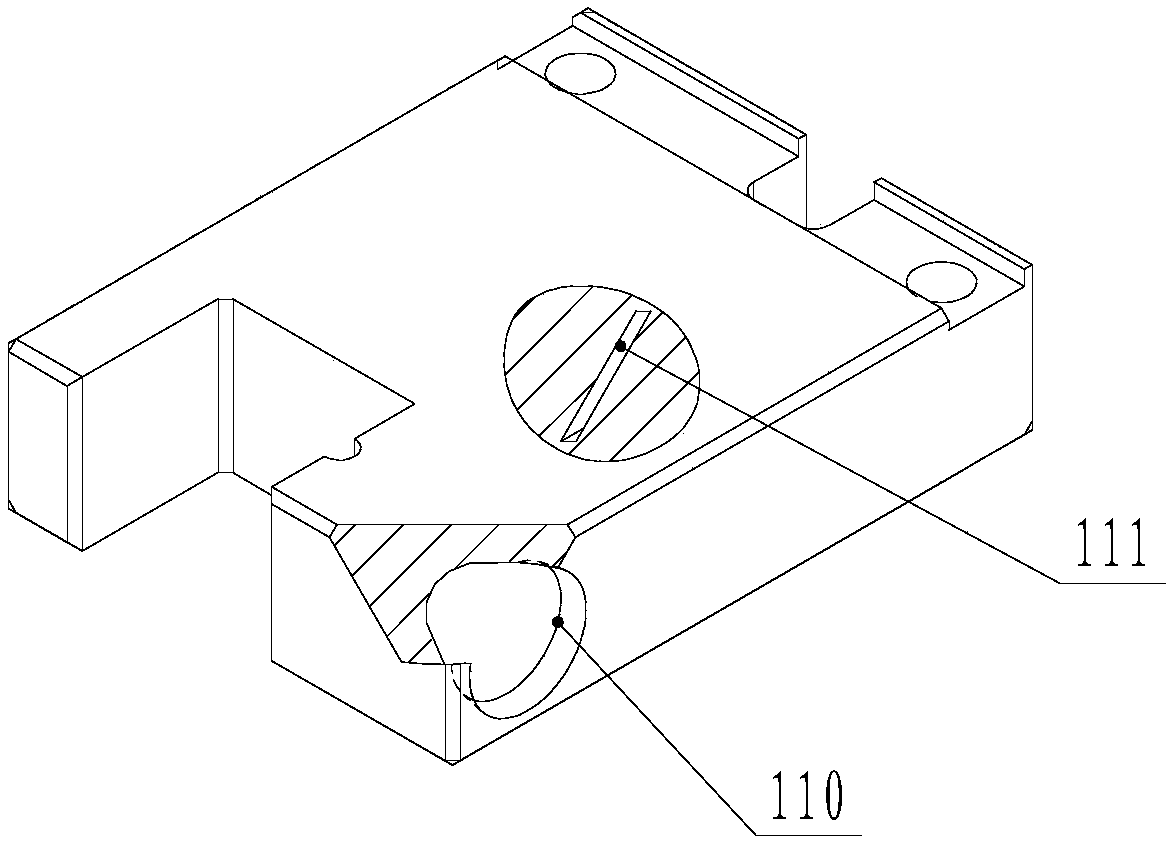

[0025] The automatic feeding mechanism 1 includes a direct vibration module 109, a feeding block 106, a pushing rod 102, a pushing cylinder 103, a feeding pneumatic slide table 104, a laser optical fiber 105, a feeding limit plate 107 and a limit cylinder 108, the front end of the direct vibration module 109 is prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap