Cable car hanging mechanism

A hanging and cable car technology, which is applied in the field of cableway transportation, can solve problems such as inconsistent outer diameters, bumps in the hanging mechanism, and cable slippage, and achieve the effects of improving stability and reducing cable car vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

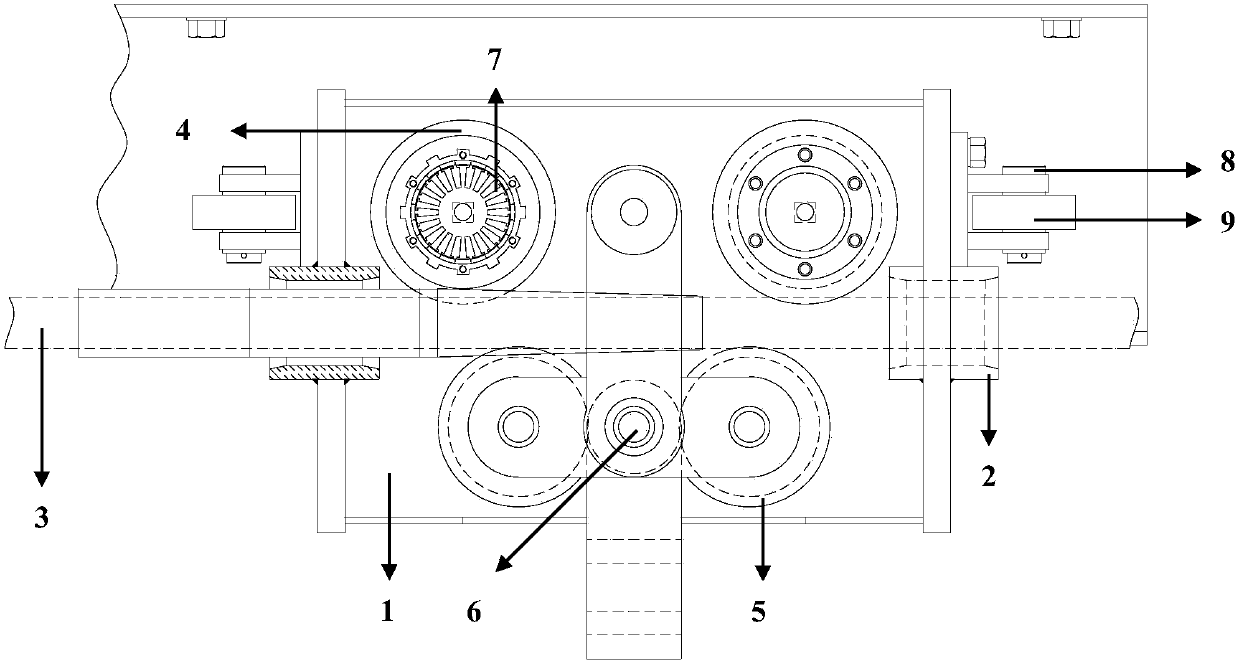

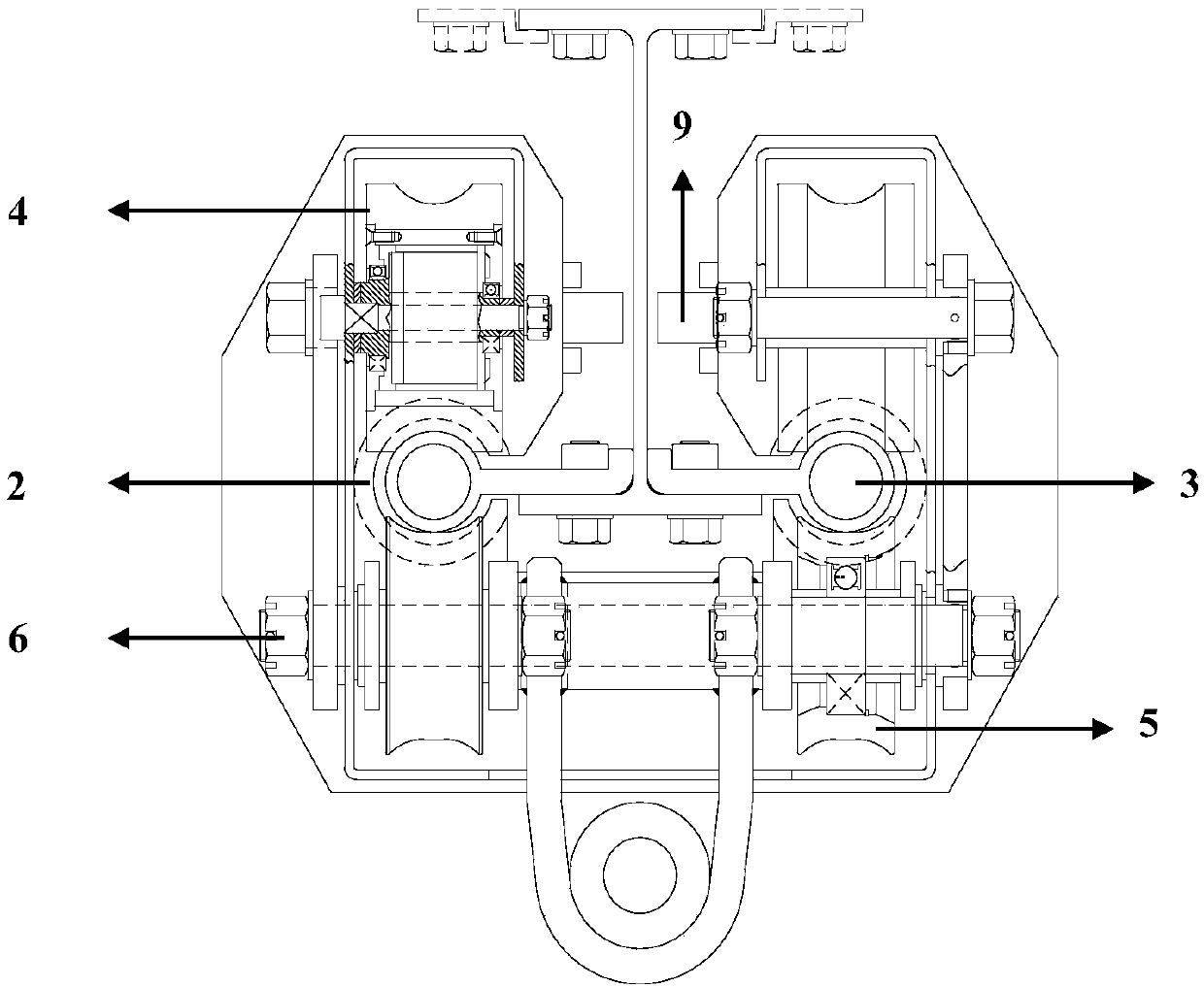

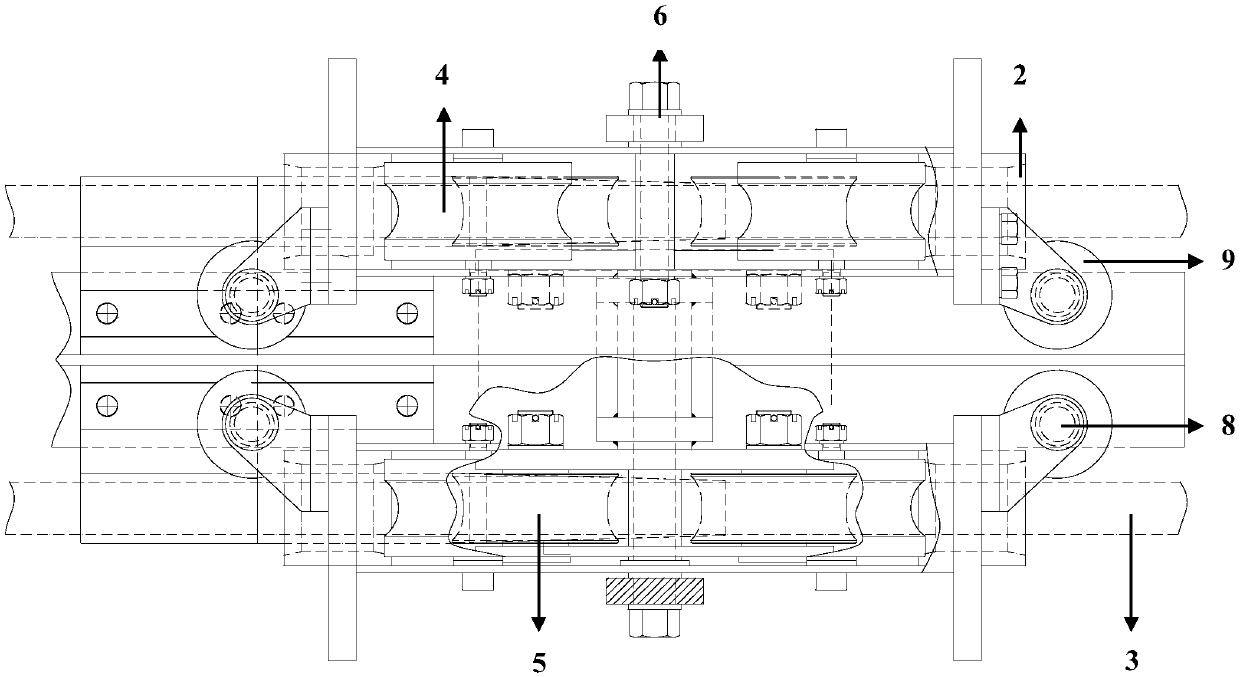

[0038] The specific embodiments of the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0039] Figure 1-Figure 3 A schematic structural diagram of a cable car suspension mechanism provided by a specific embodiment of the present invention is shown. As shown in the figure, a cable car suspension mechanism includes: a support component 1, a running mechanism arranged on the support component 1, a driving mechanism that provides driving force for the running mechanism, and is connected below the support component 1 cabin. The support member 1 is provided with a holding mechanism suitable for the passage of the cable 3 and stabilizing the cable 3. The holding mechanism includes front and rear cylindrical wheels set in the traveling mechanism and supported on the cable 3. The guide groove 2, because the cables 3 need a certain support at a certain interval, such as a support column arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com