Classifying recycling device

A recovery device and mounting seat technology, which is applied in the direction of loading/unloading, transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity of workers and the impact on workers' health, so as to avoid physical health, simple and reasonable structure, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

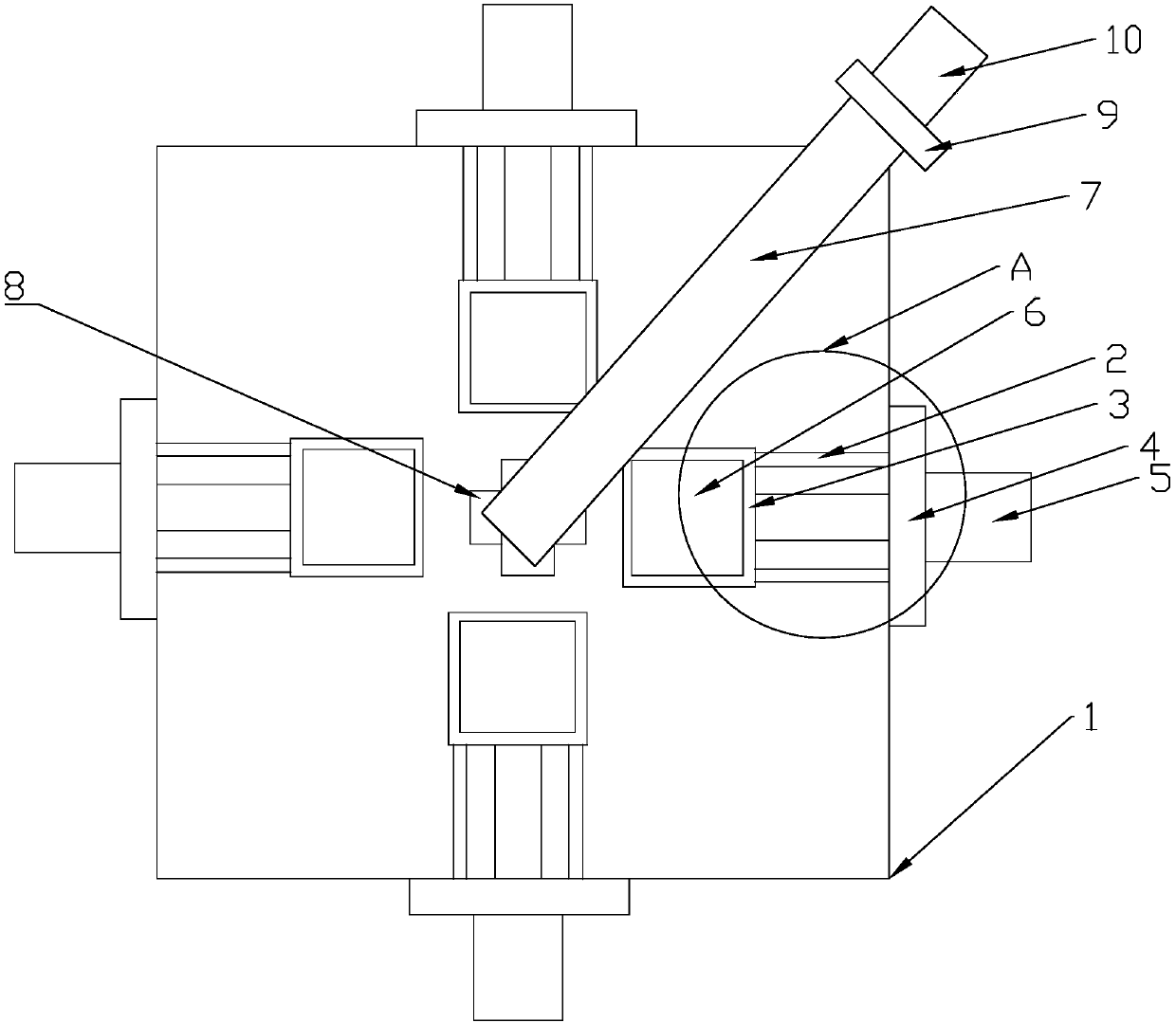

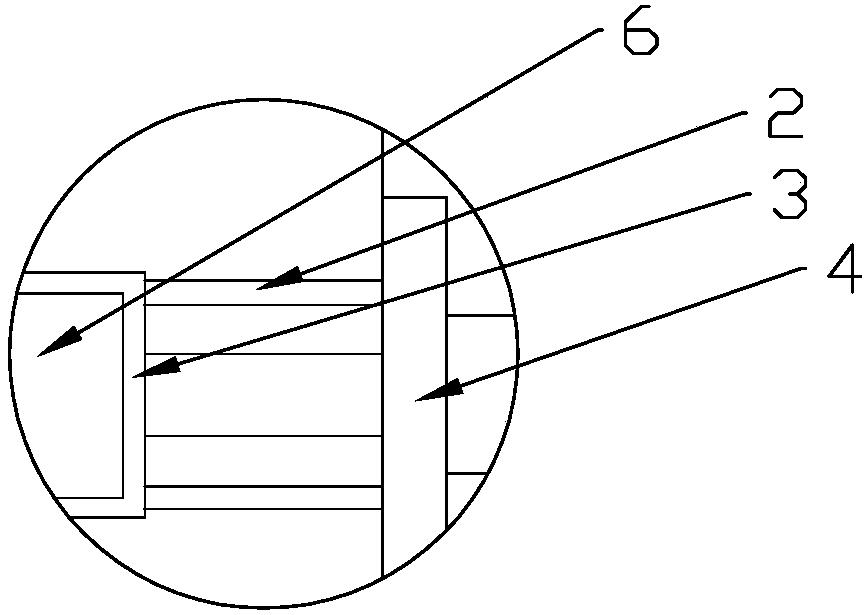

[0016] Such as Figure 1-2 As shown, the sorting and recycling device includes a base 1, a plurality of chutes 2 are arranged on the base 1, the chutes 2 face the center of the base 1, the chute 2 is slidably provided with a slider 3, and the base 1 is provided with The first installation base 4 corresponding to the chute 2 one by one, each first installation base 4 is fixed with a cylinder 5, the output end of the cylinder 5 is fixedly connected with the corresponding slider 3, and the slider 3 is provided with a collection box 6, The top of the base 1 is also provided with a guide rail 7, the guide rail 7 is slidably provided with a gripper 8, the end of the guide rail 7 is provided with a second mount 9, the second mount 9 is provided with a motor 10, and the motor 10 and the gripper 8 drive connect.

[0017] In this embodiment, in order to make the working performance of the present invention more stable and reliable, four chutes 2 are arranged on the base 1, and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com