Feeding device for dried tofu processing

A technology of a material distribution device and dried bean curd, which is applied to mixers with a rotary stirring device, applications, cheese substitutes, etc., can solve the problems of increased stirring workload, unfavorable uniform stirring, and difficulty in controlling the input amount, so as to achieve the taste Coordinate stability, avoid instability, and ensure stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

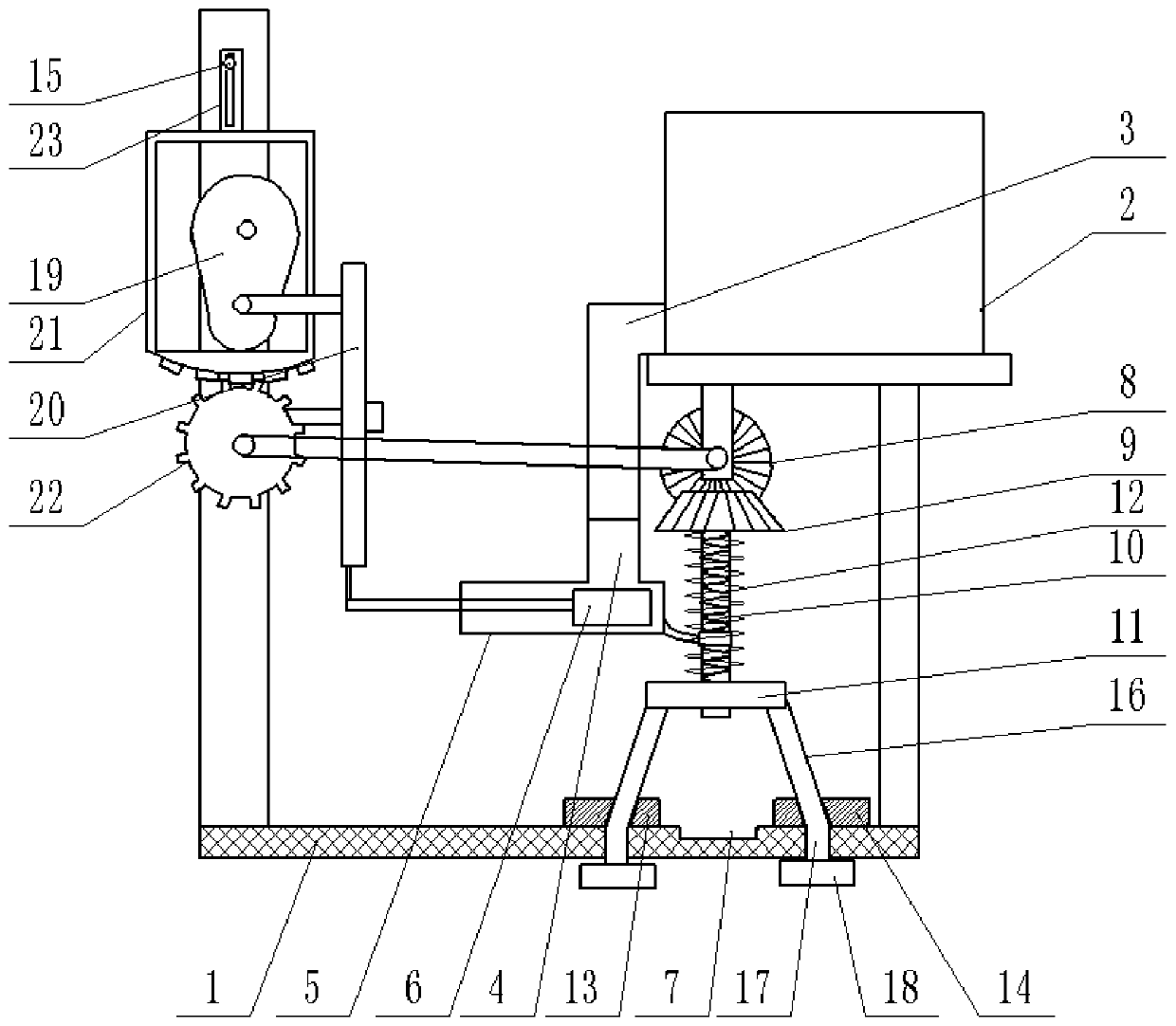

[0015] The reference signs in the drawings of the description include: frame 1, material box 2, discharge pipe 3, vertical pipe 4, horizontal pipe 5, piston 6, positioning groove 7, first bevel gear 8, second bevel gear 9, Threaded pipe 10, connecting plate 11, spring 12, first slide block 13, second slide block 14, positioning shaft 15, inclined bar 16, straight bar 17, anti-off block 18, cam 19, lever 20, frame 21, straight Gear 22, hanging bar 23.

[0016] The embodiment is basically as figure 1 Shown: the material distributing device for dried tofu processing, including frame 1, on which frame 1 is provided with material box 2, material box 2 includes discharge pipe 3, and discharge pipe 3 is threadedly connected with T-shaped pipe, T-shaped pipe It includes a horizontal tube 5 and a vertical tube 4. The vertical tube 4 communicates with the discharge tube 3. The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com