System and method for machining integral blisks with auxiliary flushing electrolytic milling

An integral blisk and milling technology, which is applied in the field of electrolytic grinding combined processing, can solve the problems of restricting the promotion and industrial application of electrolytic milling and grinding processing technology, poor processing stability, and reduced electrolyte flow rate, etc., to achieve improved processing Stability, promote rapid discharge, reduce loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings.

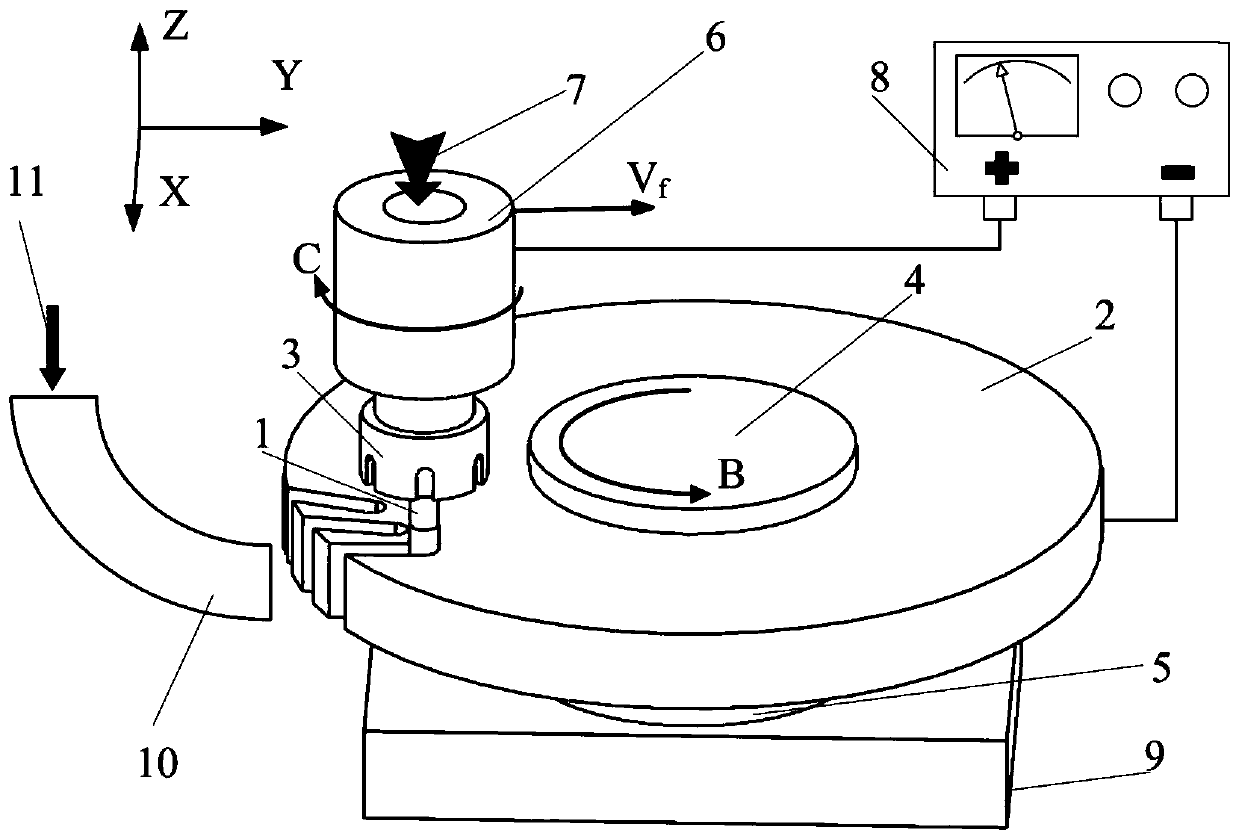

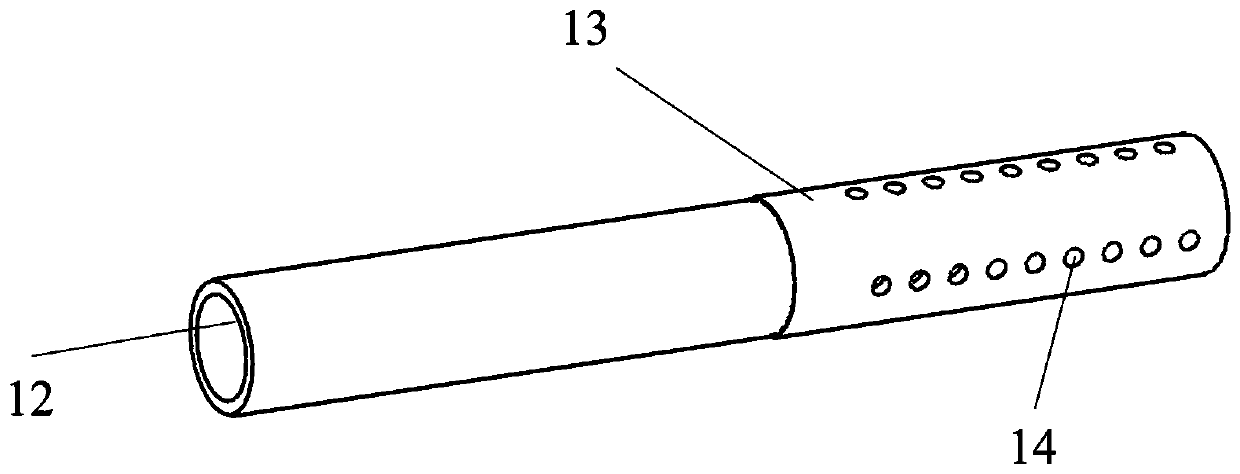

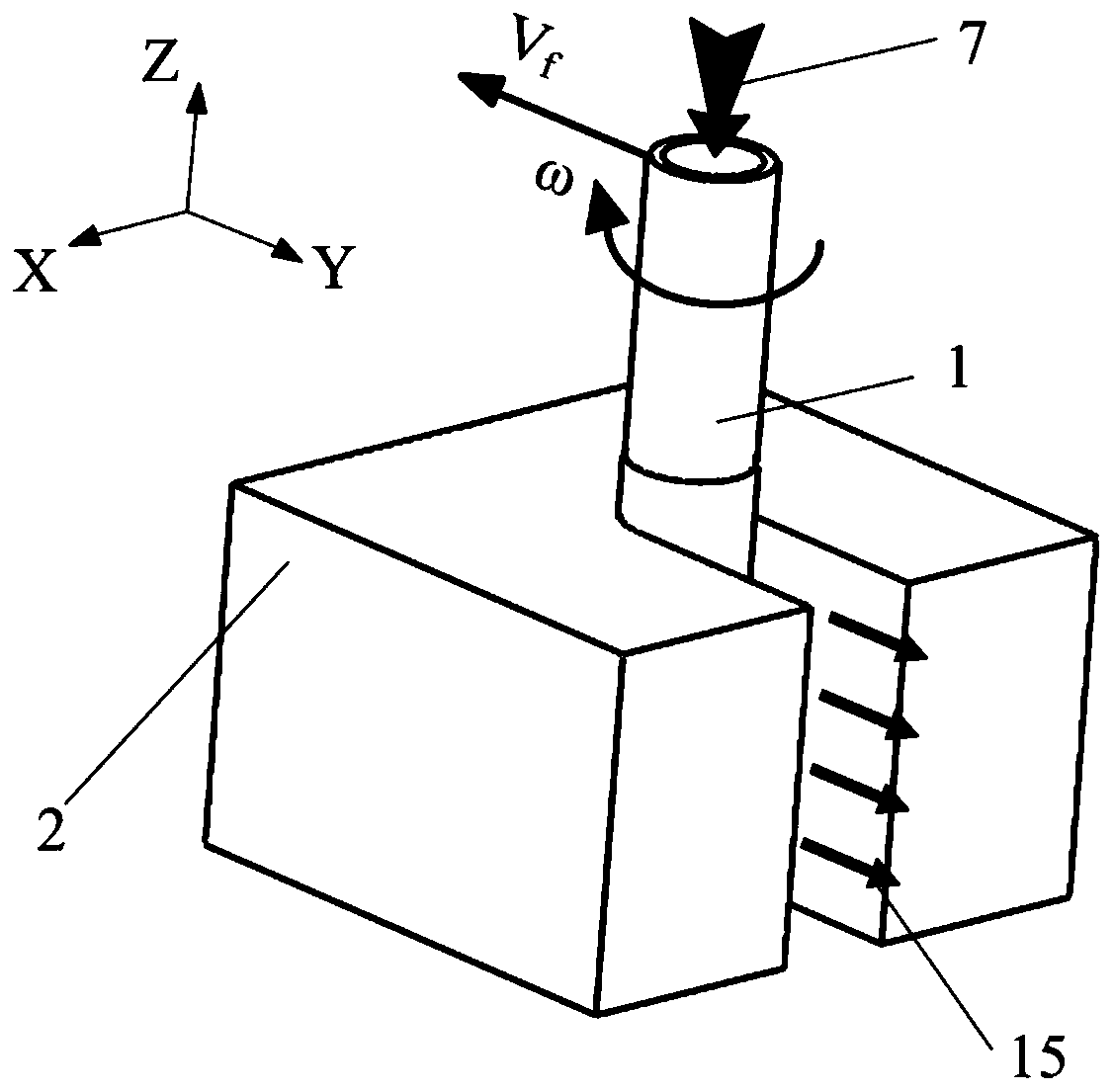

[0029] Such as figure 1 , figure 2 with Figure 4 As shown, the tool cathode 1 is clamped on the end of the main shaft 6 with a through hole through the chuck nut 3, and the blisk blank 2 is clamped on the support shaft 5 of the worktable 9 through the pressing plate 4. The tool cathode 1 is connected to the negative electrode of the power source 8, and the blisk blank 2 is connected to the positive electrode of the power source 8. The tool cathode 1 has blind holes 12 and a number of liquid outlet holes, and is plated with a diamond abrasive grain layer 13. The auxiliary nozzle 10 has the same cross-sectional shape as the groove processed by the blisk blank 2 and faces the surface to be processed of the blisk blank 2. The tool cathode 1 is positioned between the auxiliary nozzle 10 and the surface to be processed of the blisk blank 2 before processing, and maintains a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com