A dual-fuel gas turbine bleed air purging method

A gas turbine, dual-fuel technology, applied in combustion methods, combustion chambers, combustion equipment and other directions, can solve the problems of inflammability and explosion, difficult storage and transportation, energy waste, etc., achieve good matching, reduce equipment investment, improve The effect of reliability and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

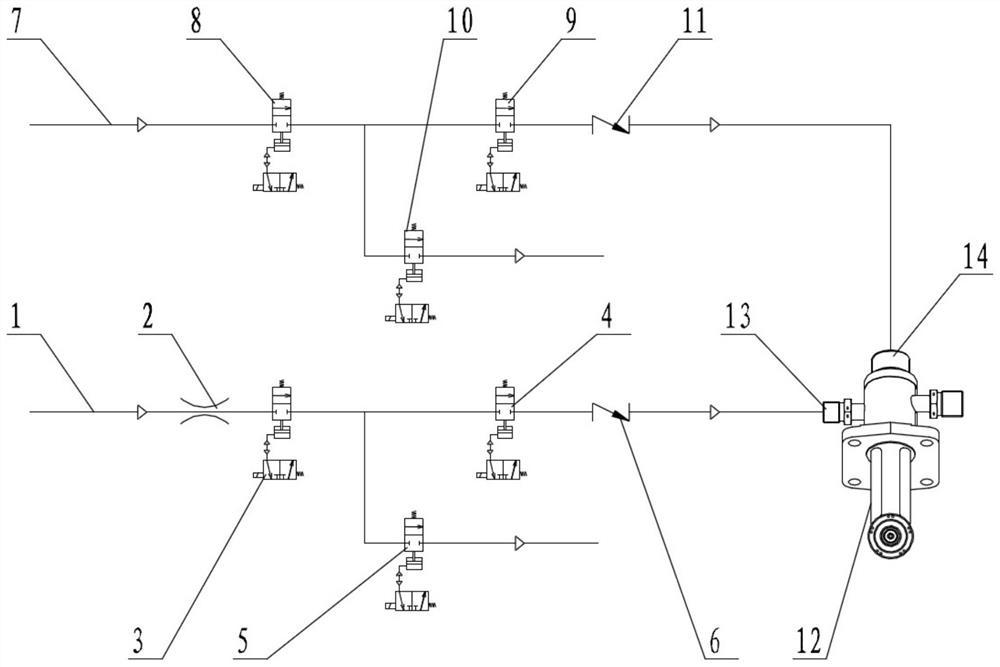

[0012] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0013] combine figure 1 , the specific implementation of the fuel channel bleed air purging system: the fuel purging pipeline 1 is connected with the throttle assembly 2 and the first-stage fuel purging circuit cut-off valve 3 in turn; A branch pipeline is connected to the second-stage fuel purging circuit cut-off valve 4, and is connected to the fuel purging circuit emptying valve 5 through the second branch pipeline; the second-stage fuel purging circuit cut-off valve 4 is connected to the first check valve 6 is connected; the first check valve 6 is connected with the fuel passage port 13 on the dual fuel nozzle 12 .

[0014] The specific implementation of the gas channel bleed purging system: the gas purging pipeline 7 is connected to the first-stage gas purging circuit cut-off valve 8; The second-stage gas purging circuit cut-off valve 9 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com