Spliced rubber outer tire positioning frame and placing structure thereof

A positioning frame and splicing technology, which is applied in the direction of tool storage devices and manufacturing tools, can solve the problems of increased assembly cost, deformation of the outer tire, inconvenient retrieval, etc., and achieve the goal of reducing equipment usage, facilitating later assembly, and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

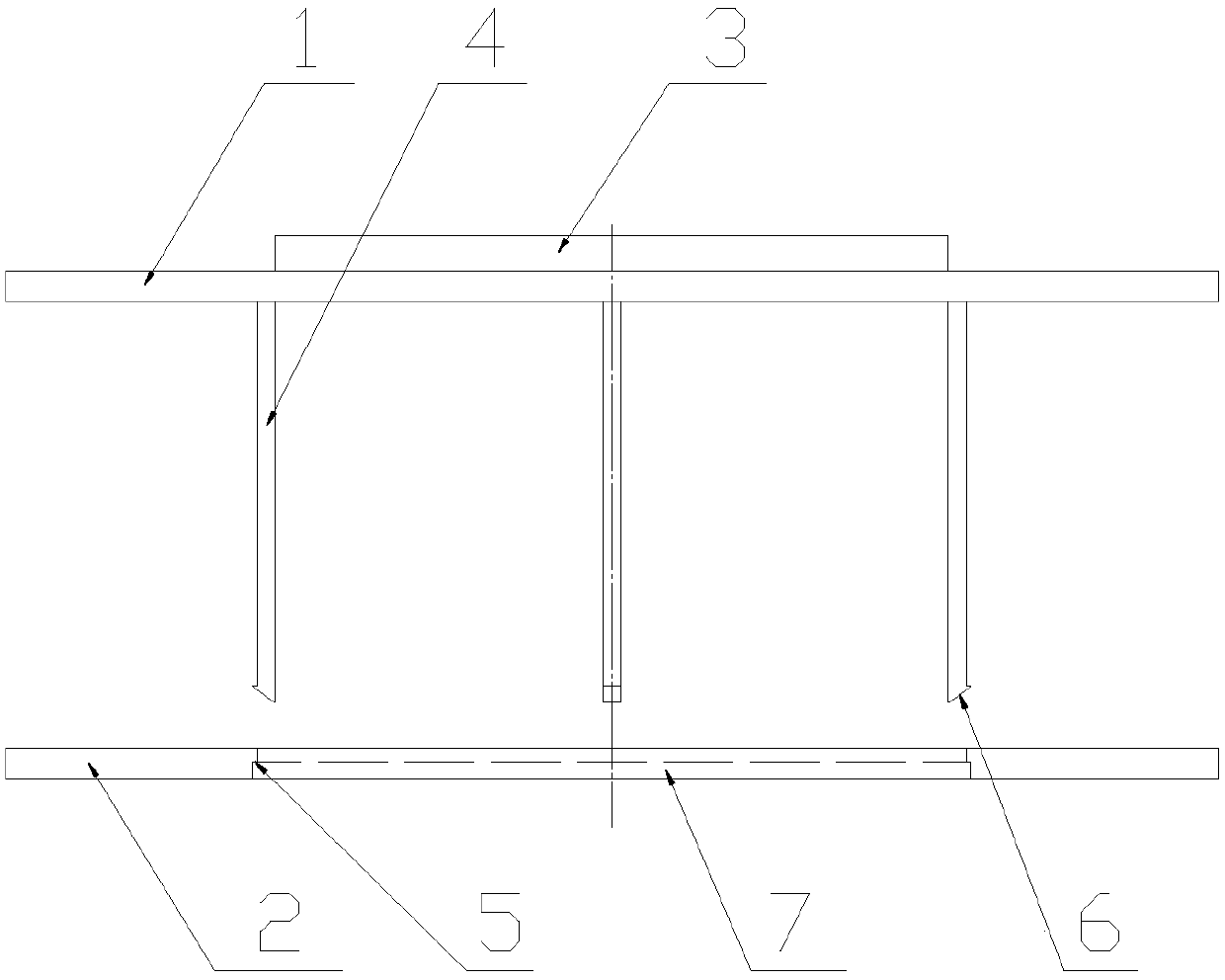

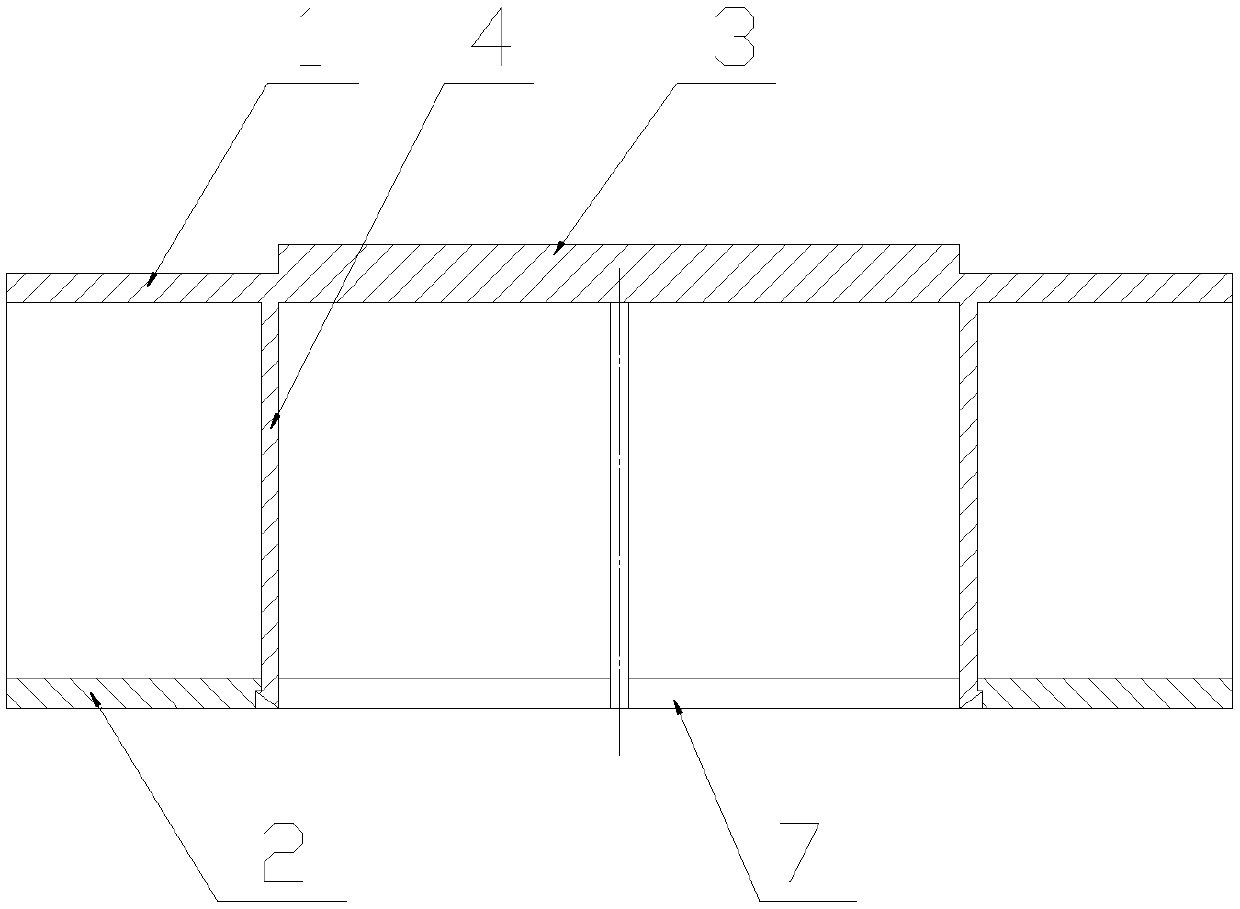

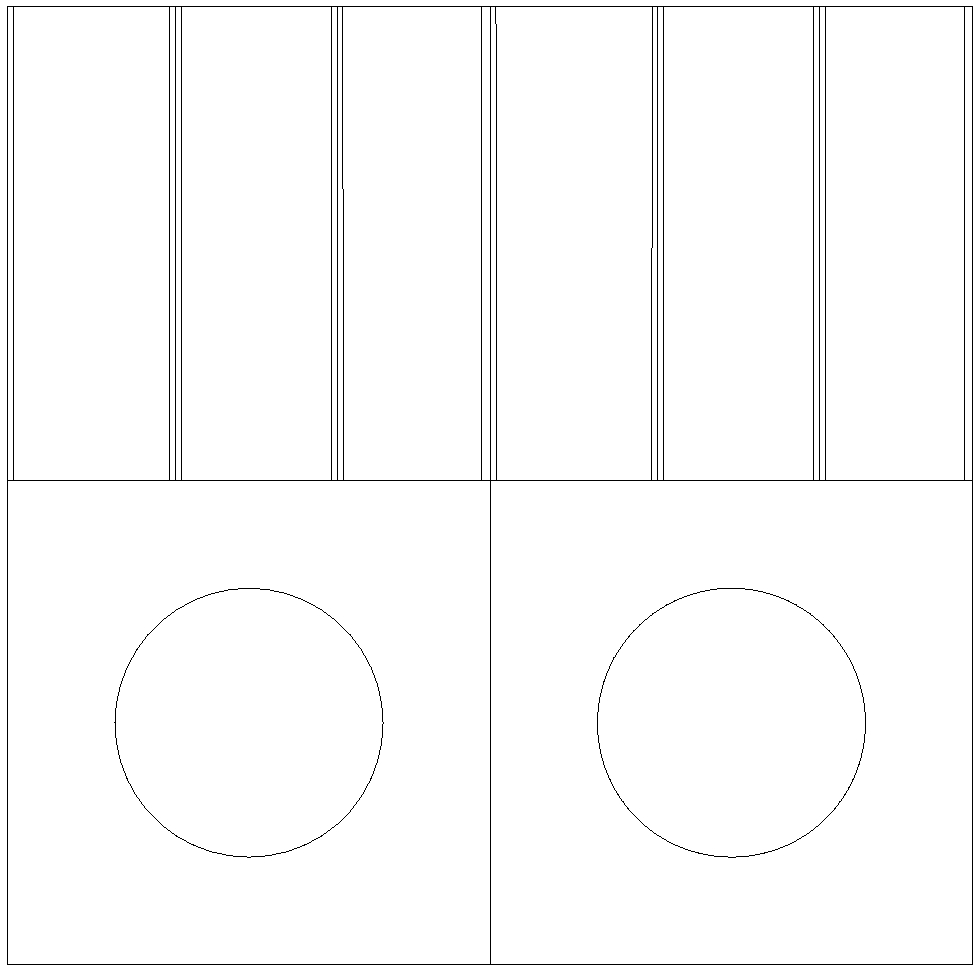

[0023] see figure 1 , figure 2 , a spliced rubber tire positioning frame, including a square first fixed plate, a second fixed plate, the first fixed plate, the second fixed plate parallel to each other and corresponding in shape, the first fixed plate, the second fixed plate The clamping space of rubber tire is formed between the fixed plates, the distance between the first fixed plate and the second fixed plate is equal to the thickness of the rubber tire, and the side length of the first fixed plate and the second fixed plate is equal to the outer surface of the rubber tire. diameter, the inner wall of the first fixing plate is provided with a number of fixing strips evenly distributed in a ring shape, and each fixing strip extends toward the direction of the second fixing plate. In this embodiment, the first fixing plate, the second fixing The materials of the plate and the fixing strip are plastics. The number of the fixing strips is four, and they are heat-sealed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com