Chiffon elastic cord tensioning fixture and method

A technology of elastic thread and chiffon, which is applied in the field of tooling for pulling elastic thread on chiffon fabrics, can solve the problems of affecting the overall quality of the product, high difficulty coefficient of operation, and uneven spacing, so as to save working hours and ensure product quality. The effect of reducing the difficulty factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

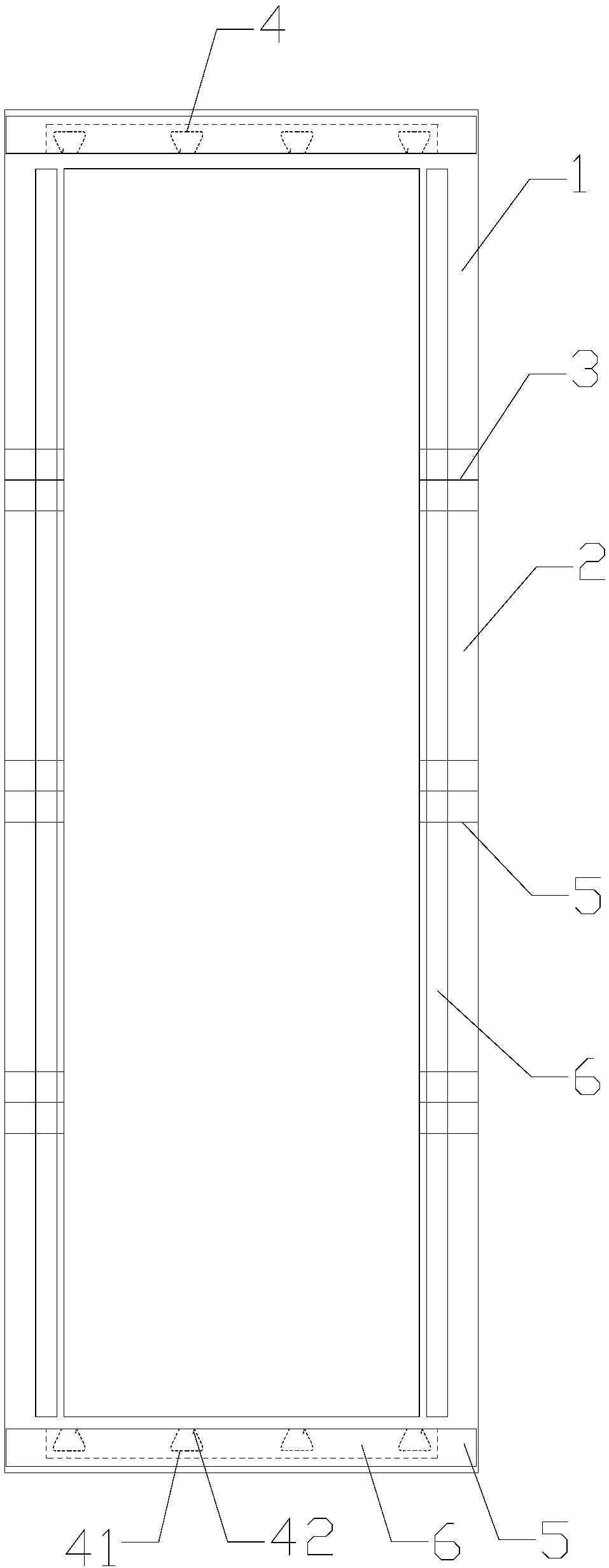

[0022] see figure 1 , the tooling used for pulling the elastic thread of chiffon cloth of the present invention comprises a square frame-type plate body 1 hollowed out in the middle. The strips 2 are butted, and the adjacent two sections of slats can be folded or unfolded at the butt seam 3, and the upper ends of the two short sides of the board body 1 are fixed with a plurality of pieces for tensioning the chiffon cloth. The special-shaped hook nail 4, a plurality of special-shaped hook nails 4 are arranged side by side at equal intervals, the special-shaped hook nail 4 includes a support part 41 for fixing the special-shaped hook nail and a tip 42 for hooking the chiffon cloth cut piece, the special-shaped hook nail 4 is formed by bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com