Rinsing tubular column capable of cleaning forward and backward

A flushing pipe string, forward and reverse technology, applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problems of poor sealing performance, low work efficiency, short service life, etc., to reduce impact , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

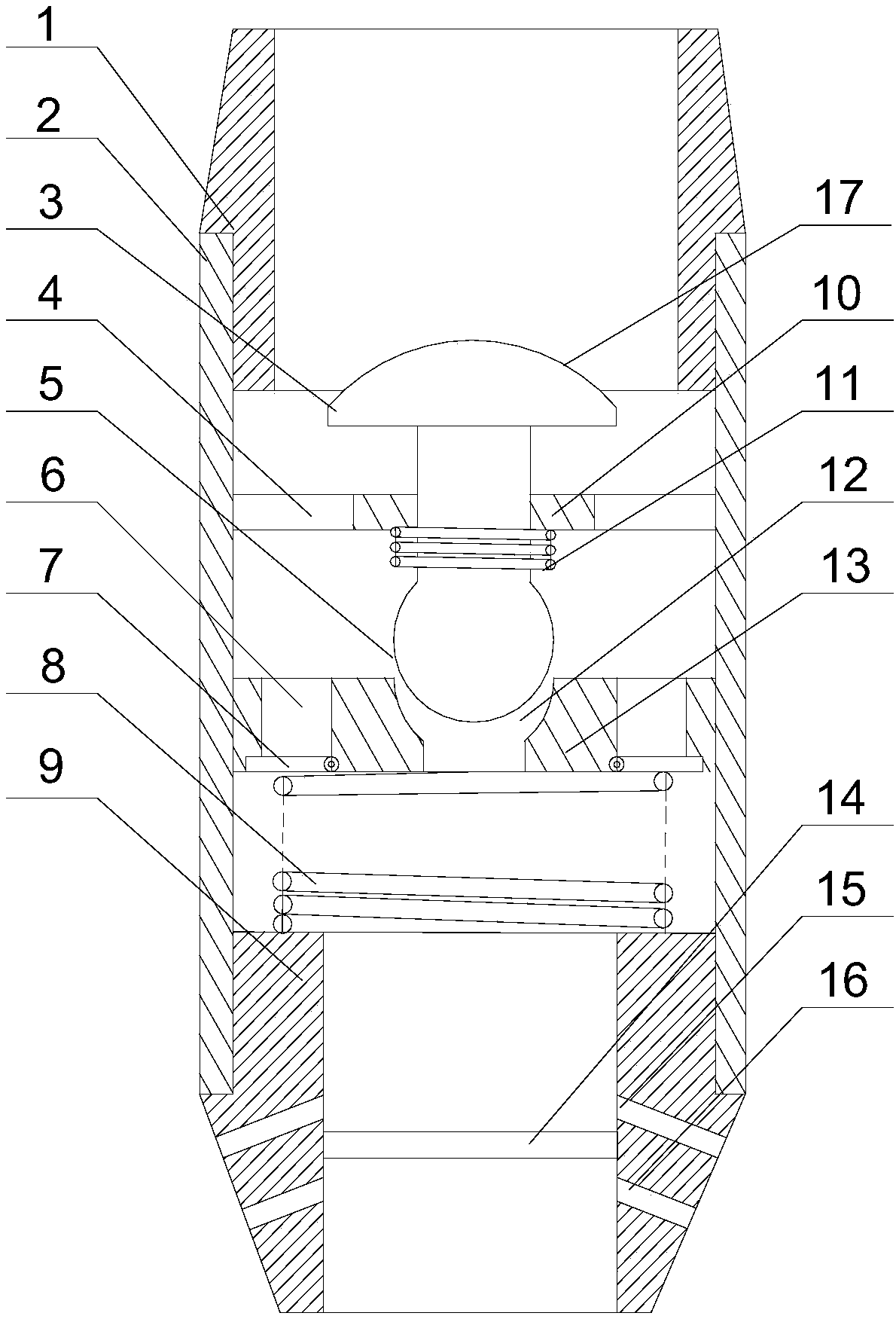

[0019] Such as figure 1 As shown, this embodiment includes a body 2 and a fixed plate 10 fixed on the inner wall of the body 2, and a packing plate 13. The upper and lower ends of the body 2 are respectively connected with an upper joint 1 and a lower joint 9. On the fixed plate 10 There are through holes 4 on both sides of the fixed plate 10, and a packing column 5 with a spring B11 is provided through the middle of the fixing plate 10, and a forward flow channel 6 is provided at both ends of the packing plate 13, and in the forward direction A baffle 7 with a spring A8 is hinged on the inner wall of the lower end of the flow channel 6, and an annular depression matching the movable end of the baffle 7 is provided on the circumference of the packing plate 13, and the middle part of the packing plate 13 is provided with a There is a reverse flow channel 12 matching the shape of the end of the isolation column 5; it also includes a filter screen 14, which is fixed in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com