Flow adjusting mechanism of air inlet model

A flow regulation and air inlet technology, applied in the field of aerodynamic testing, can solve the problems of long adjustment period, high testing cost, low testing efficiency, etc., and achieve the effect of accurately determining performance, improving testing efficiency, and simplifying adjustment steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

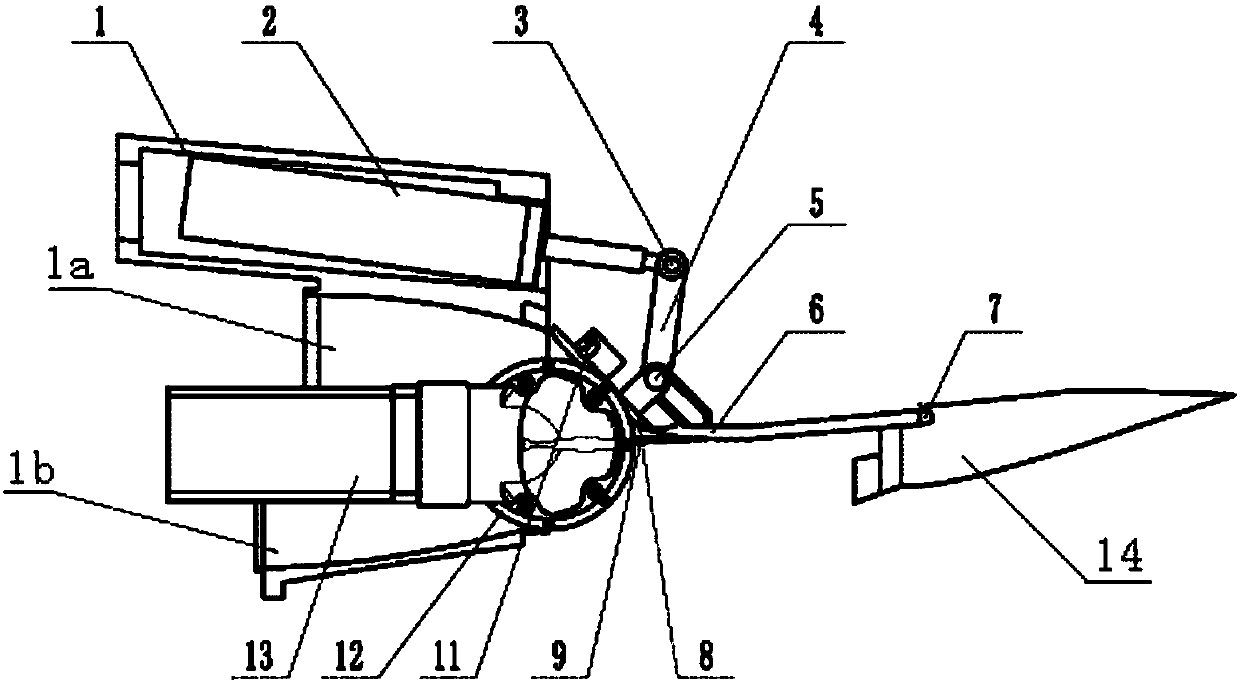

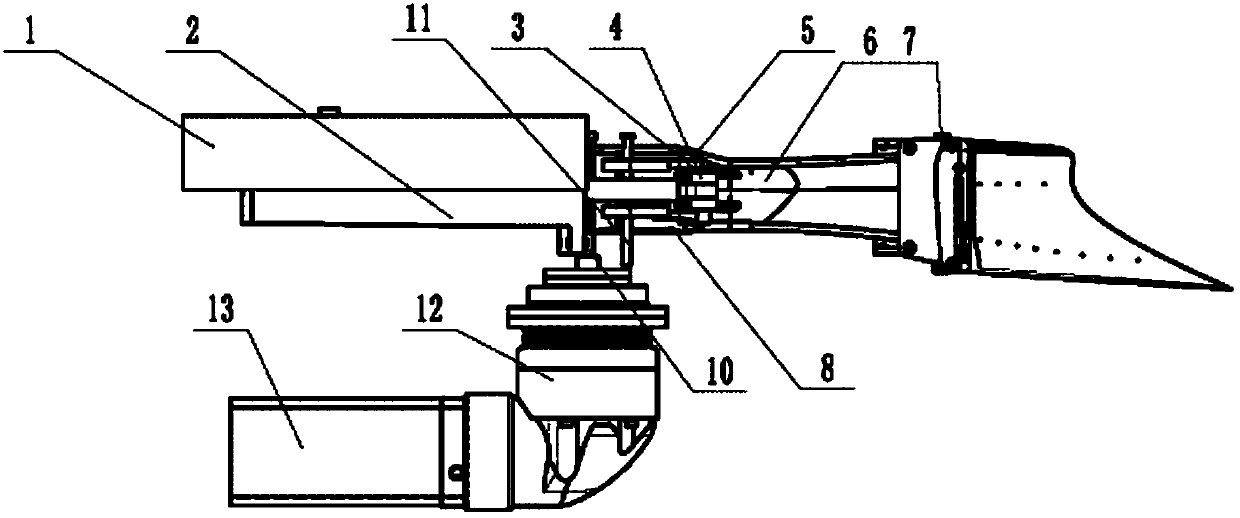

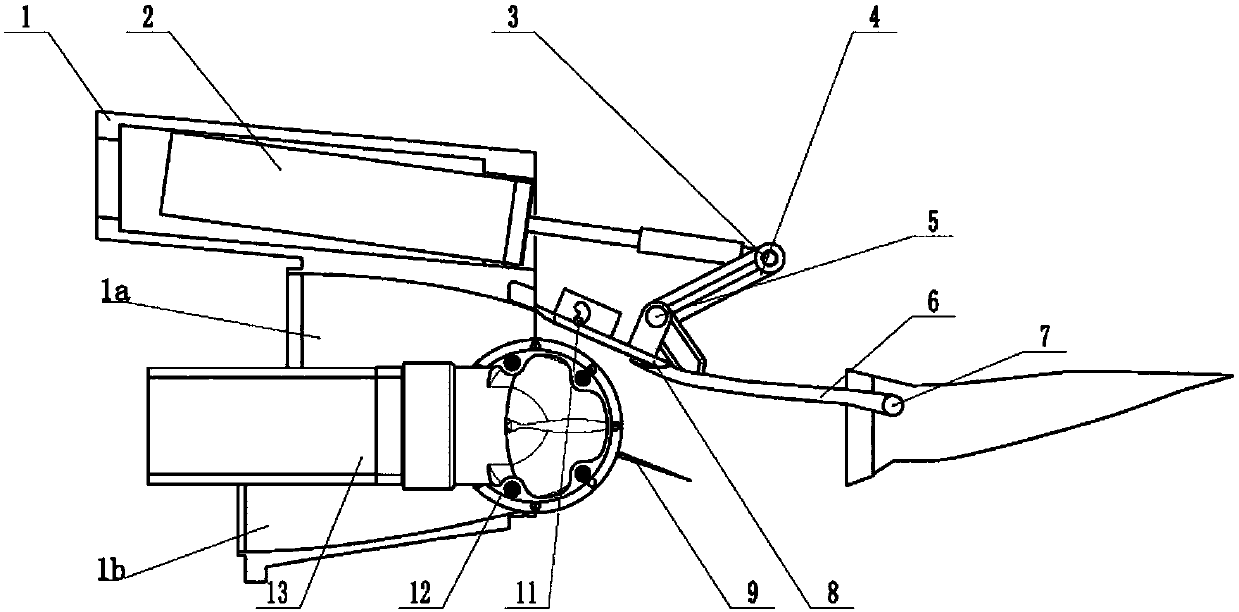

[0015] The present invention will be described in further detail below. see figure 1 , 2 , an inlet model flow regulating mechanism, including an inlet model 1, the inlet model 1 includes an inlet front section 14 and an inlet rear section, and the inlet rear section includes an upper runner 1a and a lower runner 1b, The front section 14 of the intake duct is fixed on the housing of the intake duct model 1; it is characterized in that: there is a flow regulating device, which includes an electric cylinder unit, a lower splitter plate unit and a four-bar linkage;

[0016] The electric cylinder unit includes an electric cylinder 2 and a first movable hinge shaft 3; the electric cylinder 2 is fixed on the housing of the air inlet model 1, and the piston rod of the electric cylinder 2 faces the front section 14 of the air inlet;

[0017] The lower manifold unit includes a lower manifold 9, a lower manifold shaft 11, a speed reducer 12 and a motor 13; the output shaft of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com