Panel storage device

A storage device and panel technology, which is applied in transportation and packaging, object destacking, conveyors, etc., can solve the problem of unreachable storage and handling of NG product panels, achieve simple structure, reduce the difficulty of clamping, and efficiently handle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

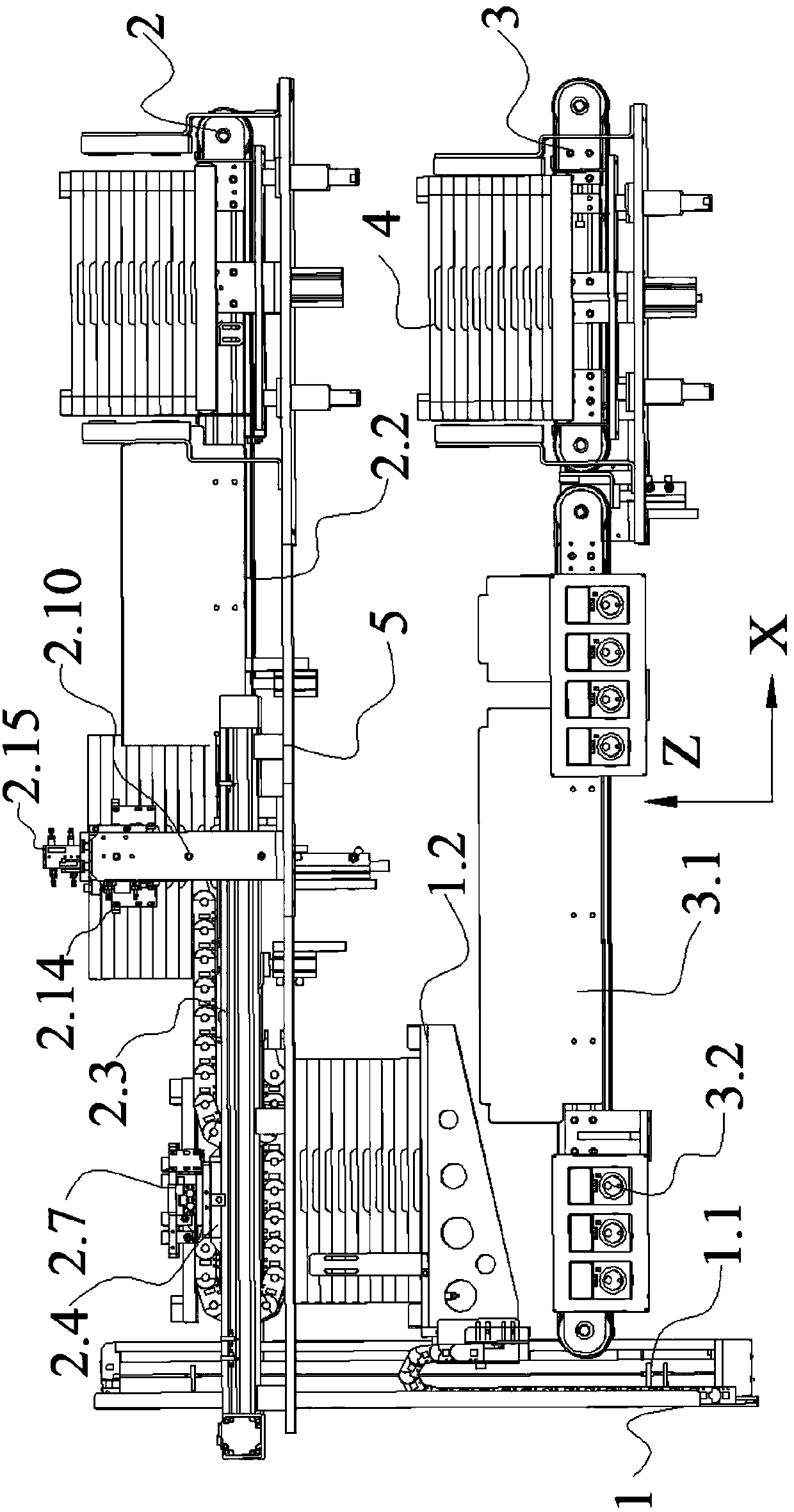

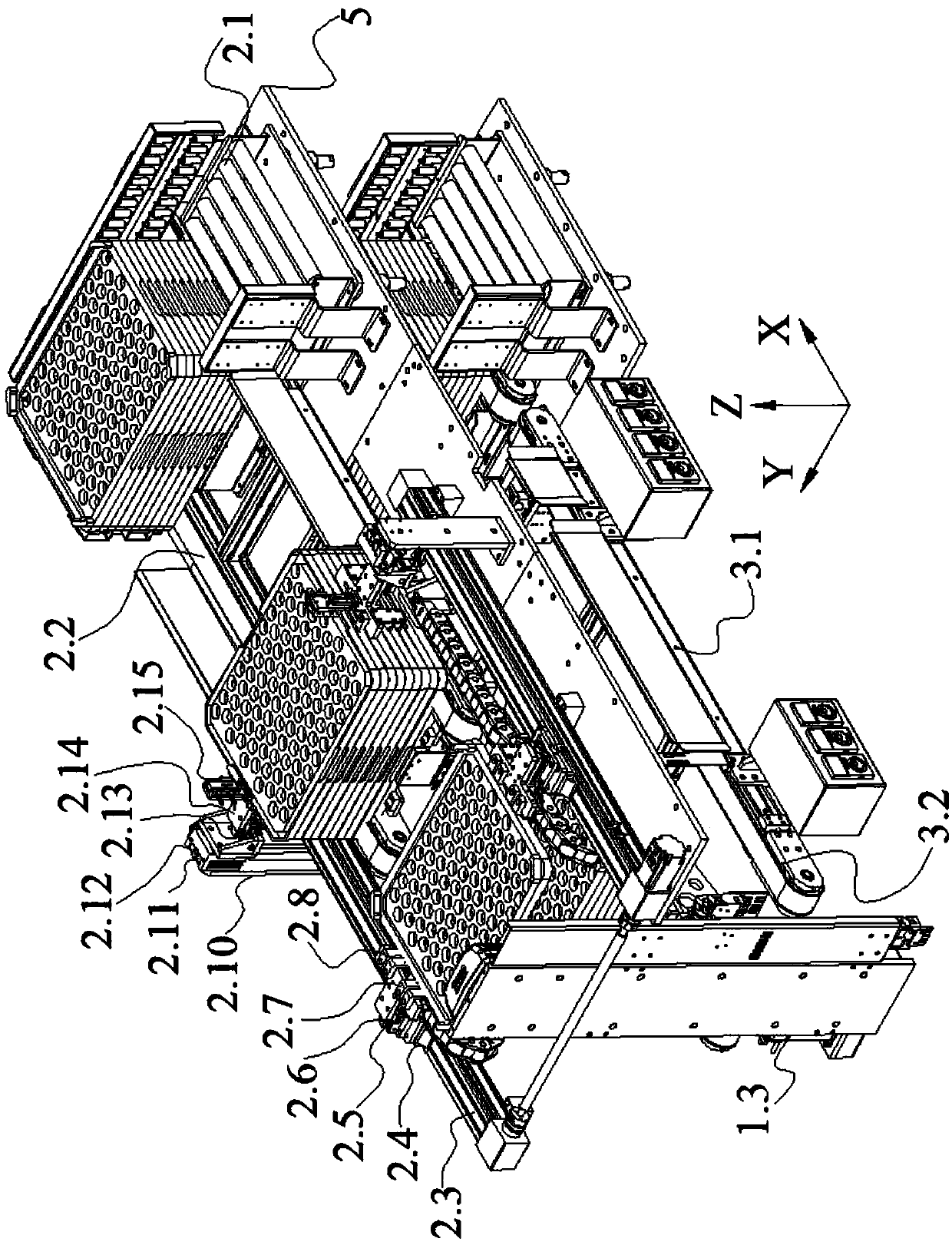

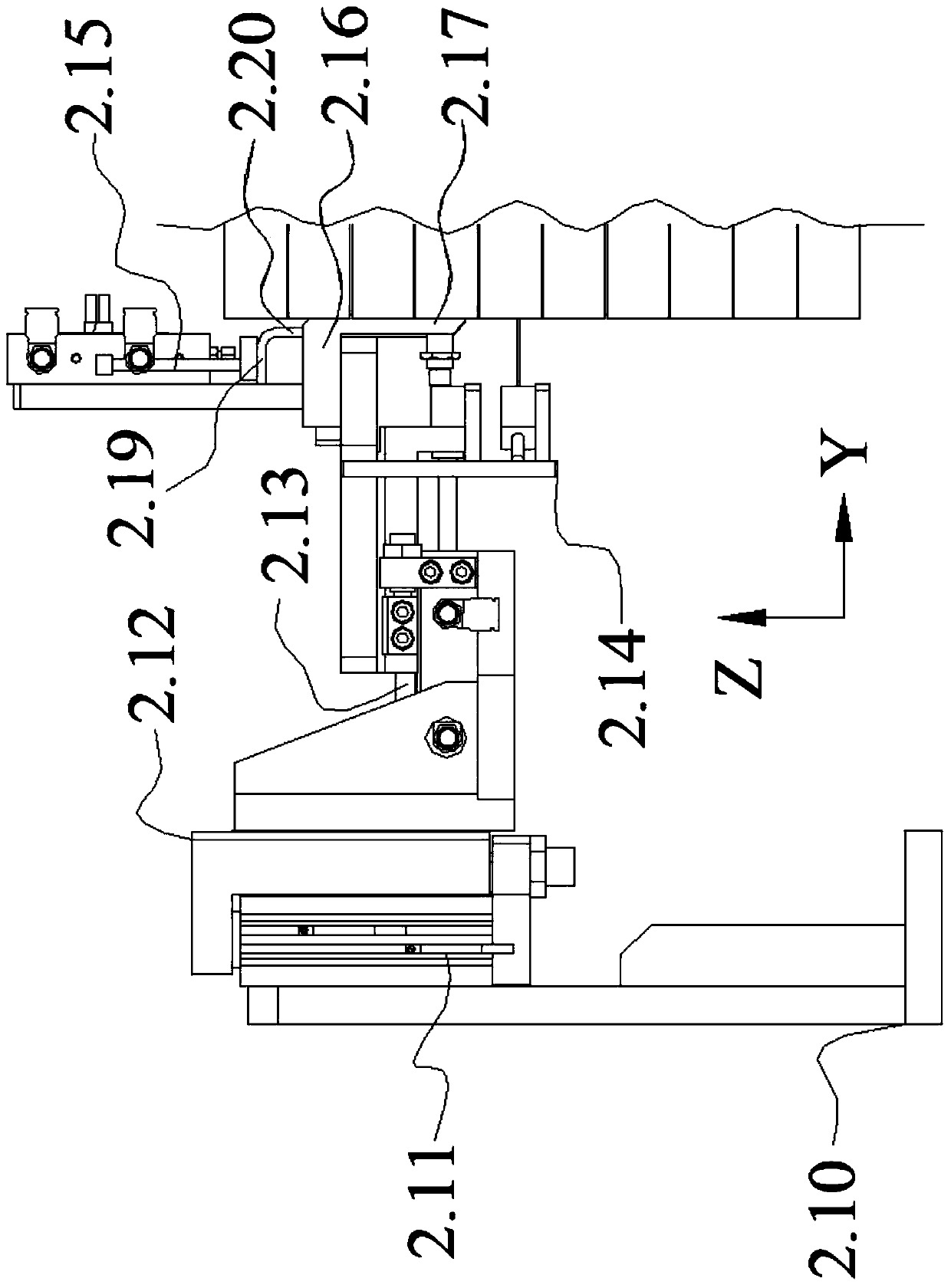

[0027] Such as Figure 1~5 , a panel storage device, including an elevator 1 for carrying and driving pallets to move up and down along the Z direction. The elevator 1 in this embodiment is used to connect the manual empty pallet placement position and the manual full pallet handling position. The elevator 1 includes a first Z guide rail 1.1 arranged along the Z direction and at least one pallet 1.2 slidably connected to the first Z guide rail 1.1. The pallet 1.2 is used to carry a pallet and pass through the The first lift cylinder 1.3 is driven to move along the Z direction. The pallet is placed on the pallet 1.2, and moves up and down along the first Z guide rail 1.1 under the action of the first lifting cylinder 1.3.

[0028] The upper end of the elevator 1 is connected with an upper platform 2, which is horizontally arranged an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap