Calibration device for volume expansion measurement instrument of solid

A volume expansion and calibration device technology, applied in the direction of measuring devices, mechanical measuring devices, volume size measurement, etc., can solve the problems of inability to reduce volume calibration, untraceable measurement results, random errors, etc., to achieve multi-point calibration, calibration Traceable with the measurement results and the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

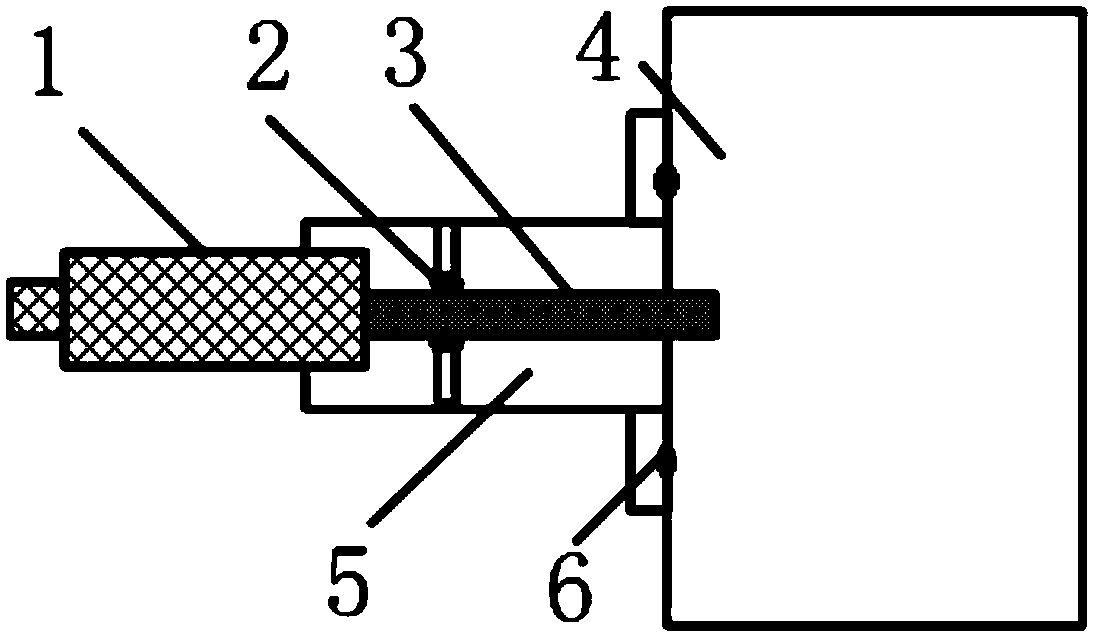

[0014] Referring to the accompanying drawings, the calibration device for solid volume dilatometers of the present invention has a hollow base 5 fixed on the front side wall of the dilatometer test chamber 4, and the base 5 is connected to the dilatometer test chamber 4 chamber walls The joint is sealed by the second annular sealing ring 6 in the form of a static sealing structure, and the first annular sealing ring 2 is set in the cavity of the base 5, and the rear screw 3 of a screw micrometer head 1 is connected by the first annular After the sealing ring 2 penetrates into the cavity of the base 5 in the form of a dynamic sealing structure, the rear end of the screw rod 3 is threaded into the test chamber 4 of the dilatometer, and a ratchet is provided at the front of the screw micrometer head 1. The rear screw rod 3 of the spiral micrometer head can be driven to reciprocate axially along the cavity of the base 5 .

[0015] The actual manufacture of the calibration device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com