Patents

Literature

56results about "Volumetric dimension measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume measurement method and system

ActiveCN109443196AFast measurementHigh measurement accuracyImage enhancementImage analysisComputer graphics (images)Visual perception

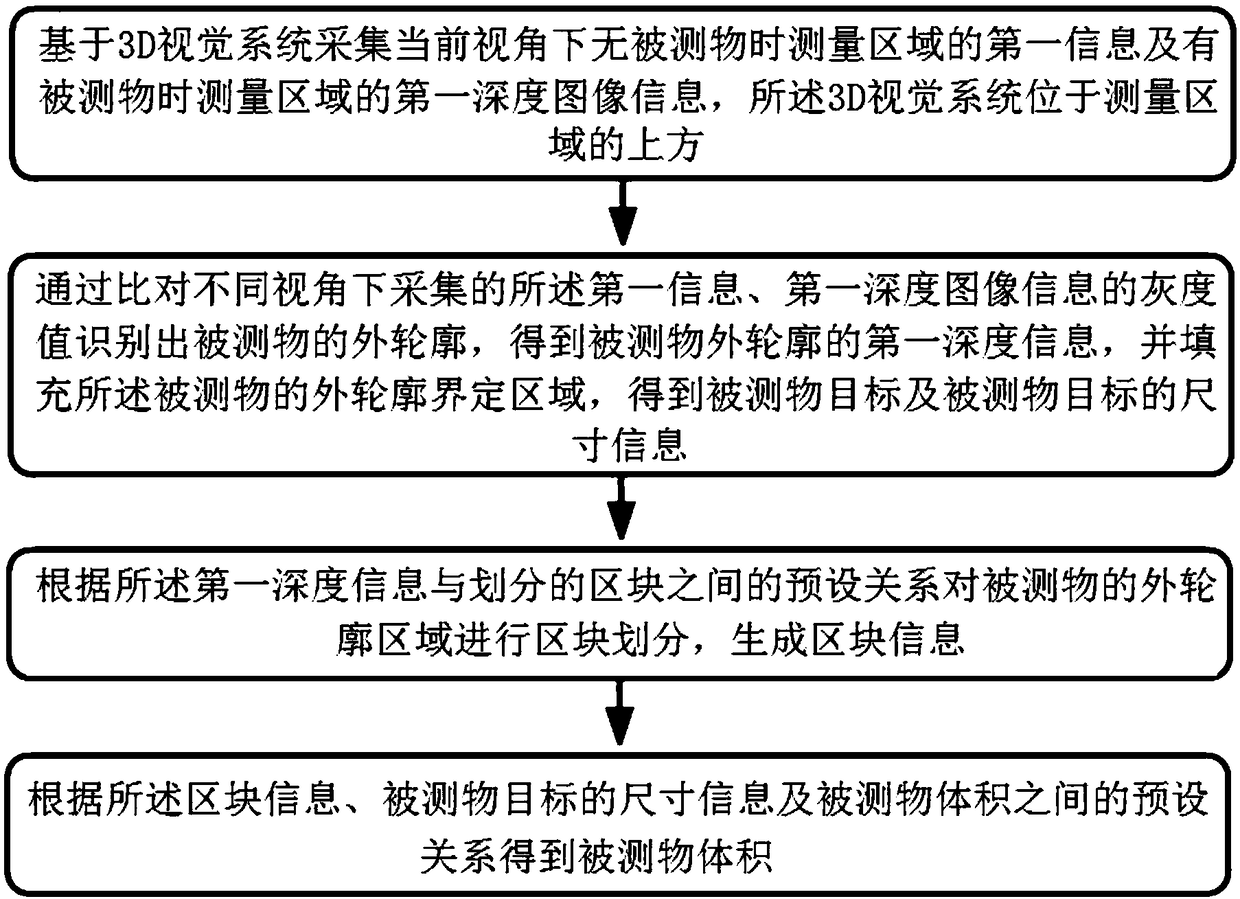

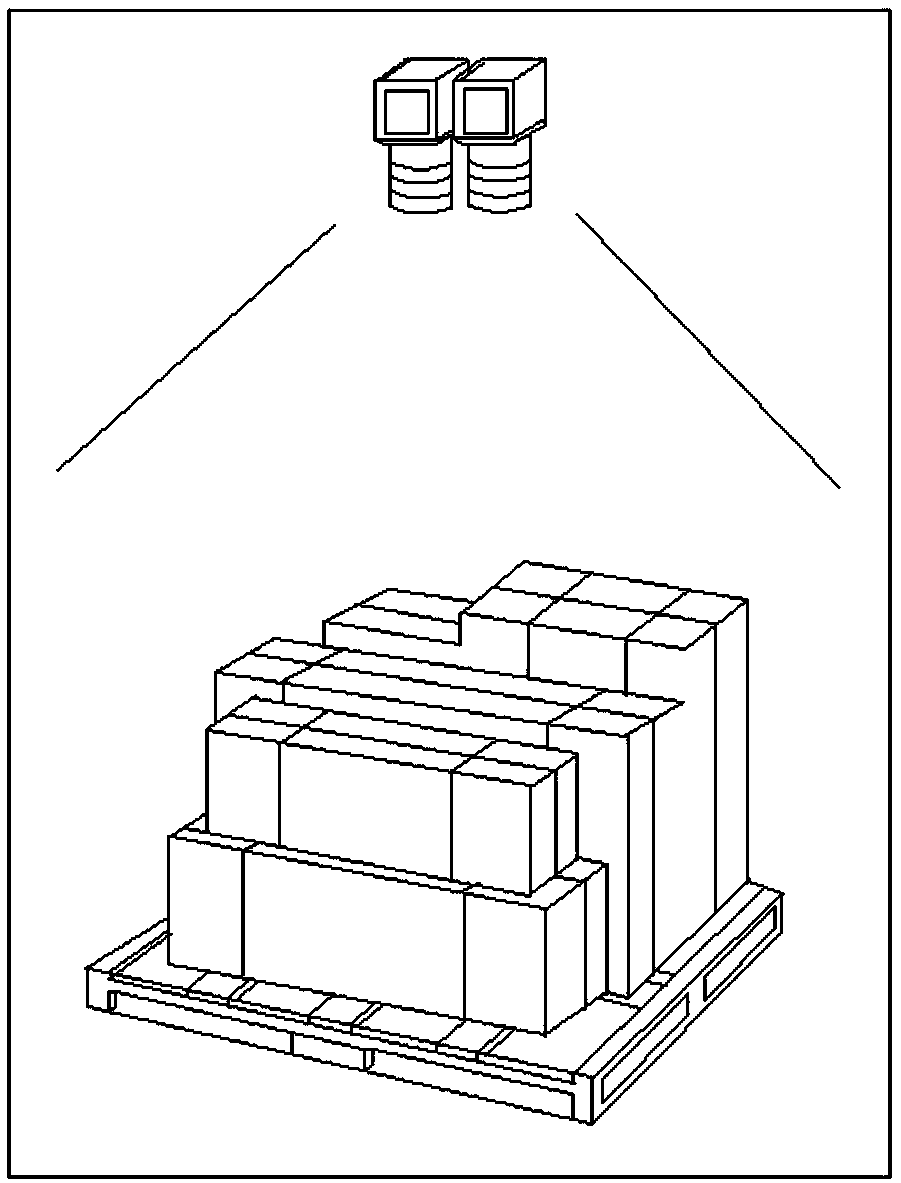

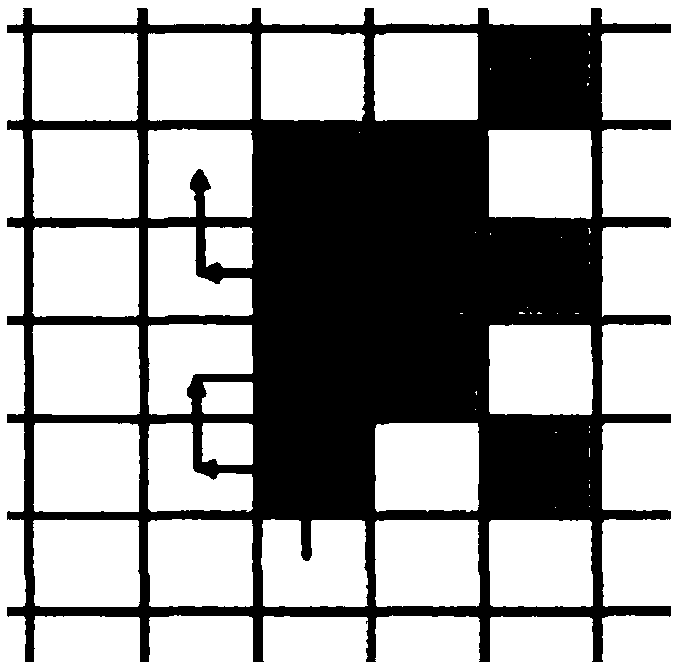

The invention relates to a volume measuring method and system, and the method is as follows: acquiring first information of the measurement area and first depth image information of the measurement area when the object to be measured exists under the current visual angle based on the 3D visual system, by comparing the first information collected at different viewing angles, and the gray value of the first depth image information identifies the outer contour of the object to be detected, the first depth information of the outer contour of the object to be measured is obtained, and the outer contour definition region of the object to be detected is filled, so as to obtain the object of the object to be detected and the size information of the object of the object to be detected; performing block division on the outer contour region of the object to be measured according to the preset relation between the first depth information and the divided blocks, generating block information; according to the block information, and obtaining the volume of the object to be measured according to the preset relation between the size information of the object to be measured and the volume of the object to be measured, testing is carried out on the basis of the 3D vision, and the measured object is directly measured, the measuring speed is high, the measuring precision is high, and the measuringrange is large.

Owner:SF TECH

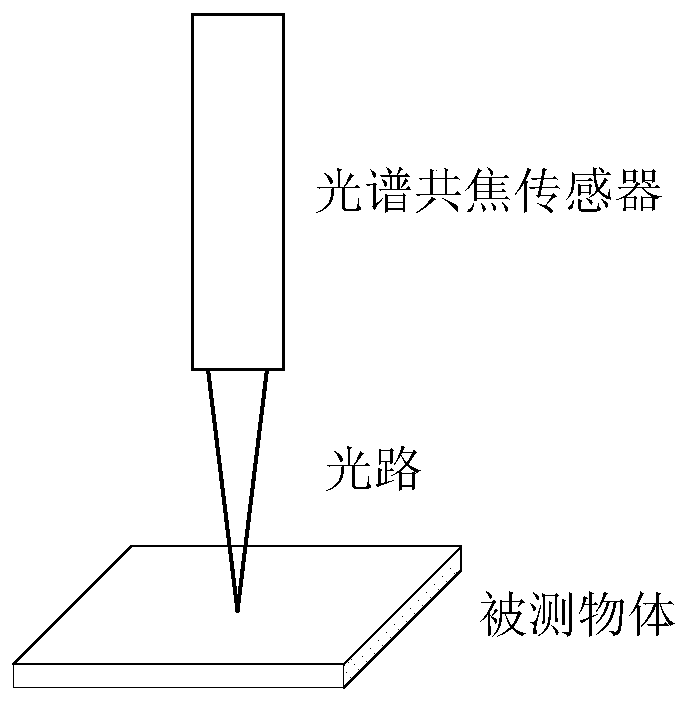

Online measurement method for effective volume of piston cylinder of piston type gas flow standard device

ActiveCN110849233ARealize non-contact measurementImprove measurement accuracyMechanical diameter measurementsUsing optical meansEngineeringDiameter measurement

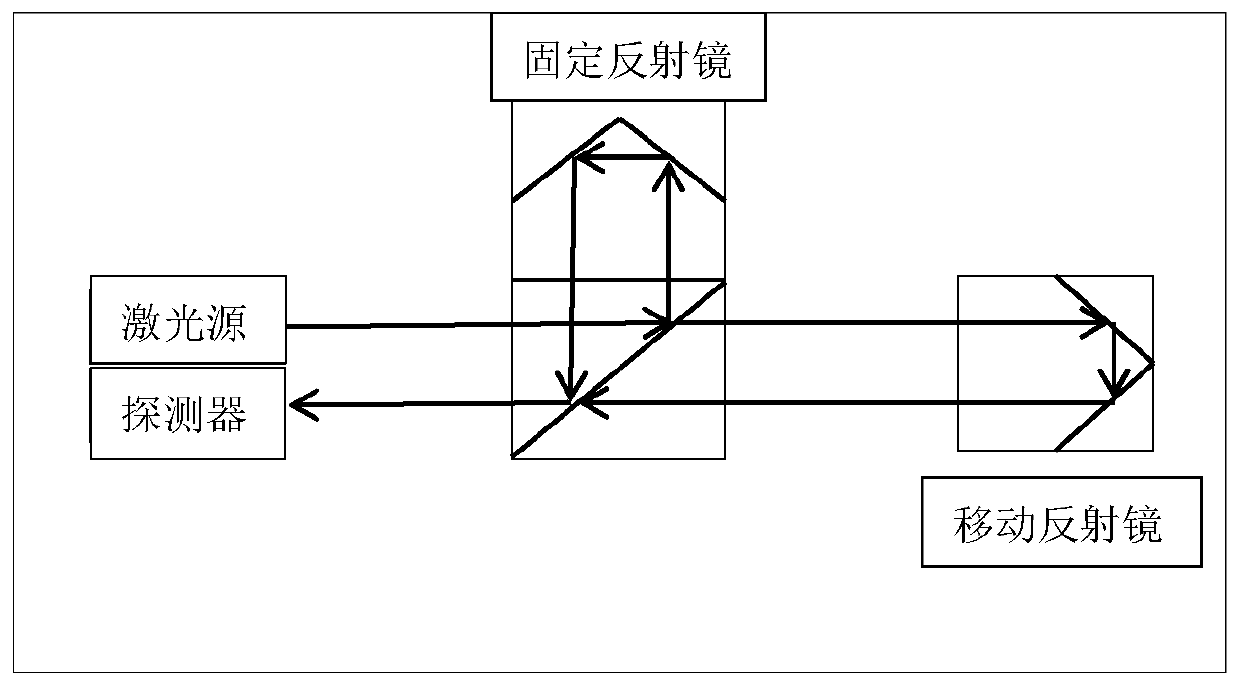

The invention discloses an online measurement method for the effective volume of a piston cylinder of a piston type gas flow standard device. Volume calibration needs to be carried out regularly in apiston type gas flow using period, a laser interferometer is used for measuring the movement distance of a piston, spectral confocal measurement technology measurement and outer diameter measurement are combined to obtain the inner diameter of a piston cylinder, and the effective volume of the piston cylinder is obtained. Therefore, periodic calibration of the volume of the piston cylinder can besimplified, on-line measurement of the volume of the piston cylinder is completed on the premise that the piston cylinder is not disassembled, and the online measurement method has the advantages of being high in measurement precision and convenient to calibrate.

Owner:NAT INST OF METROLOGY CHINA

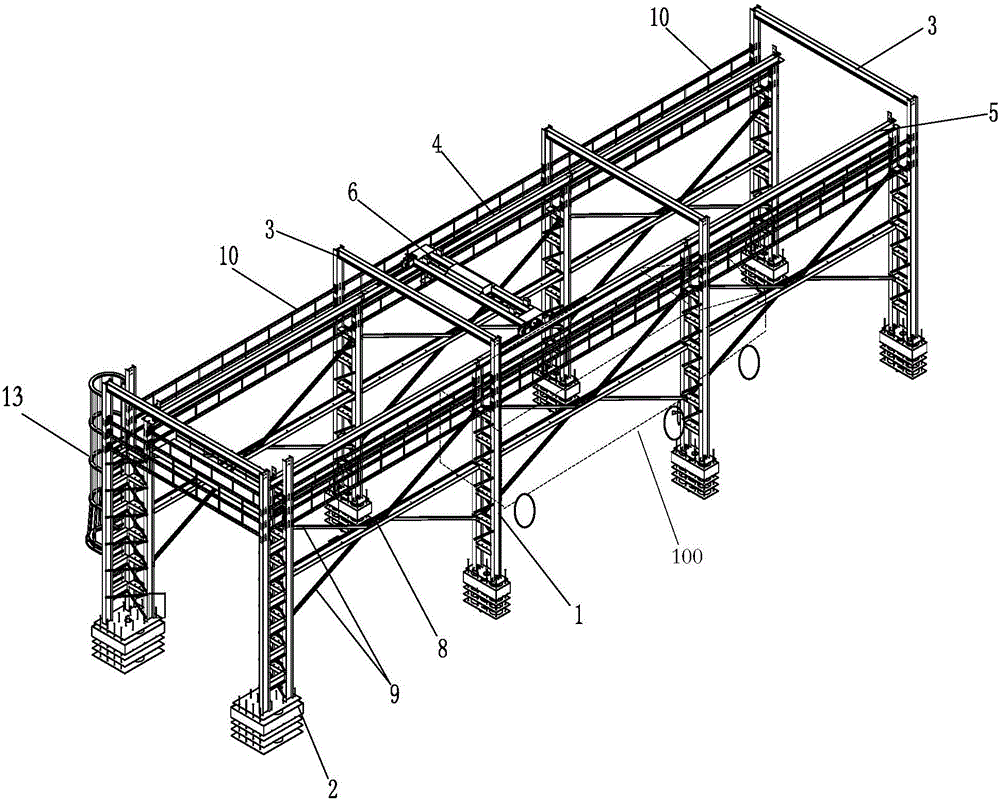

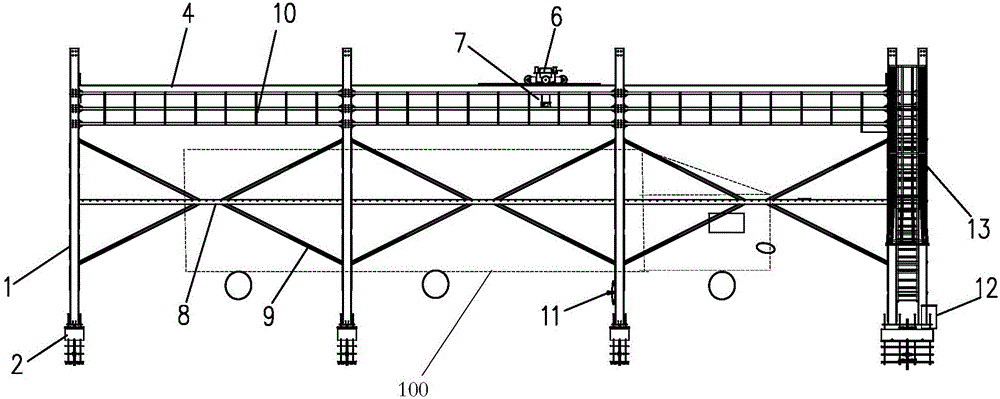

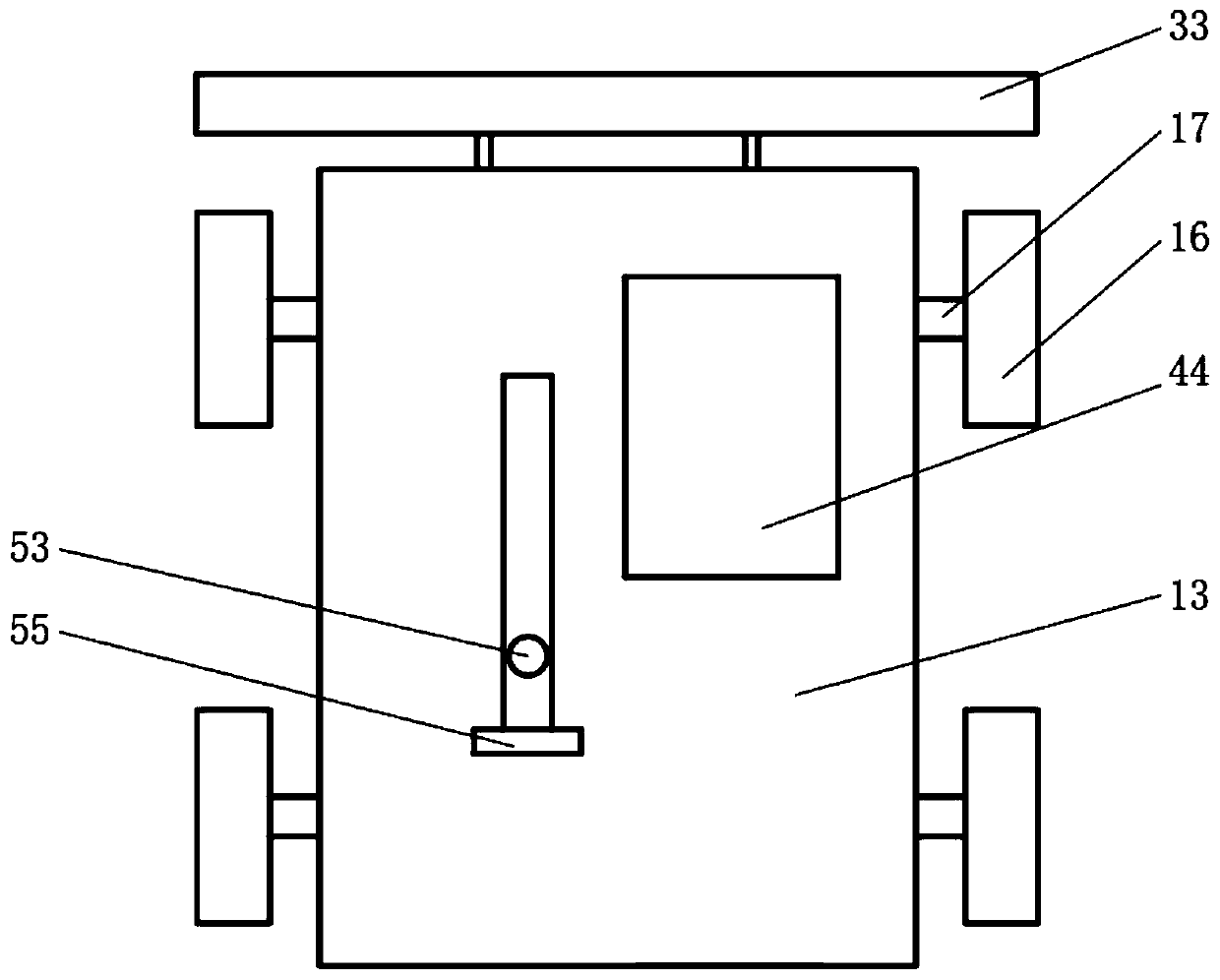

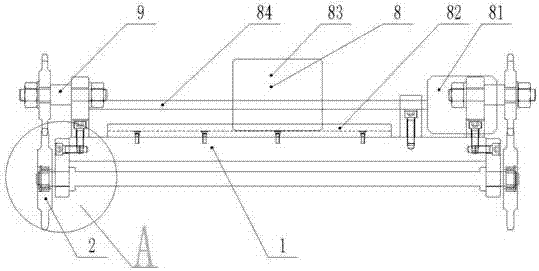

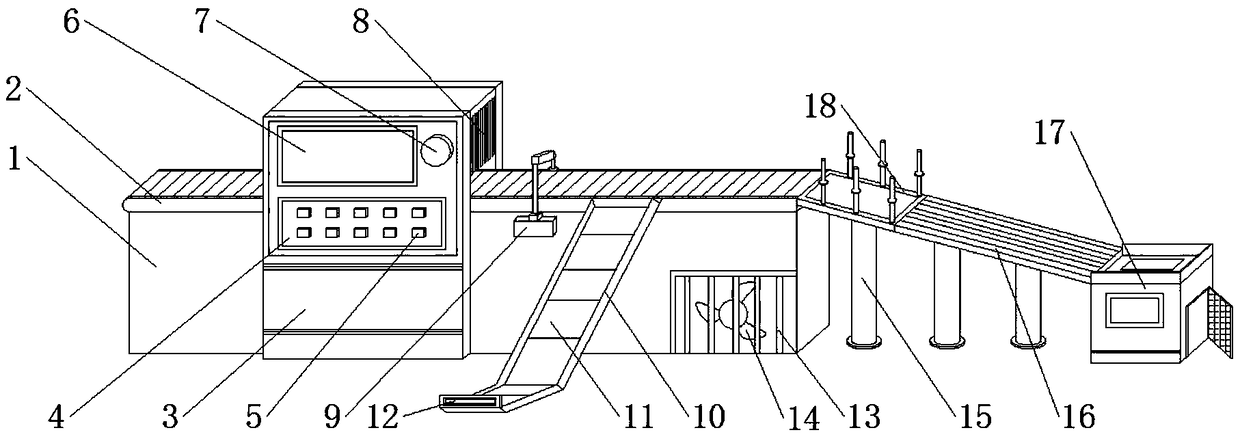

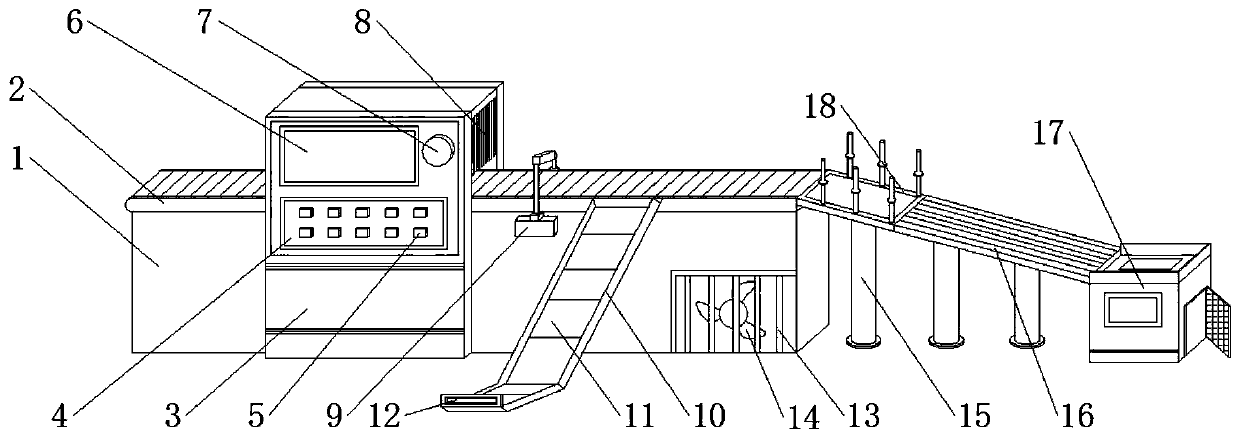

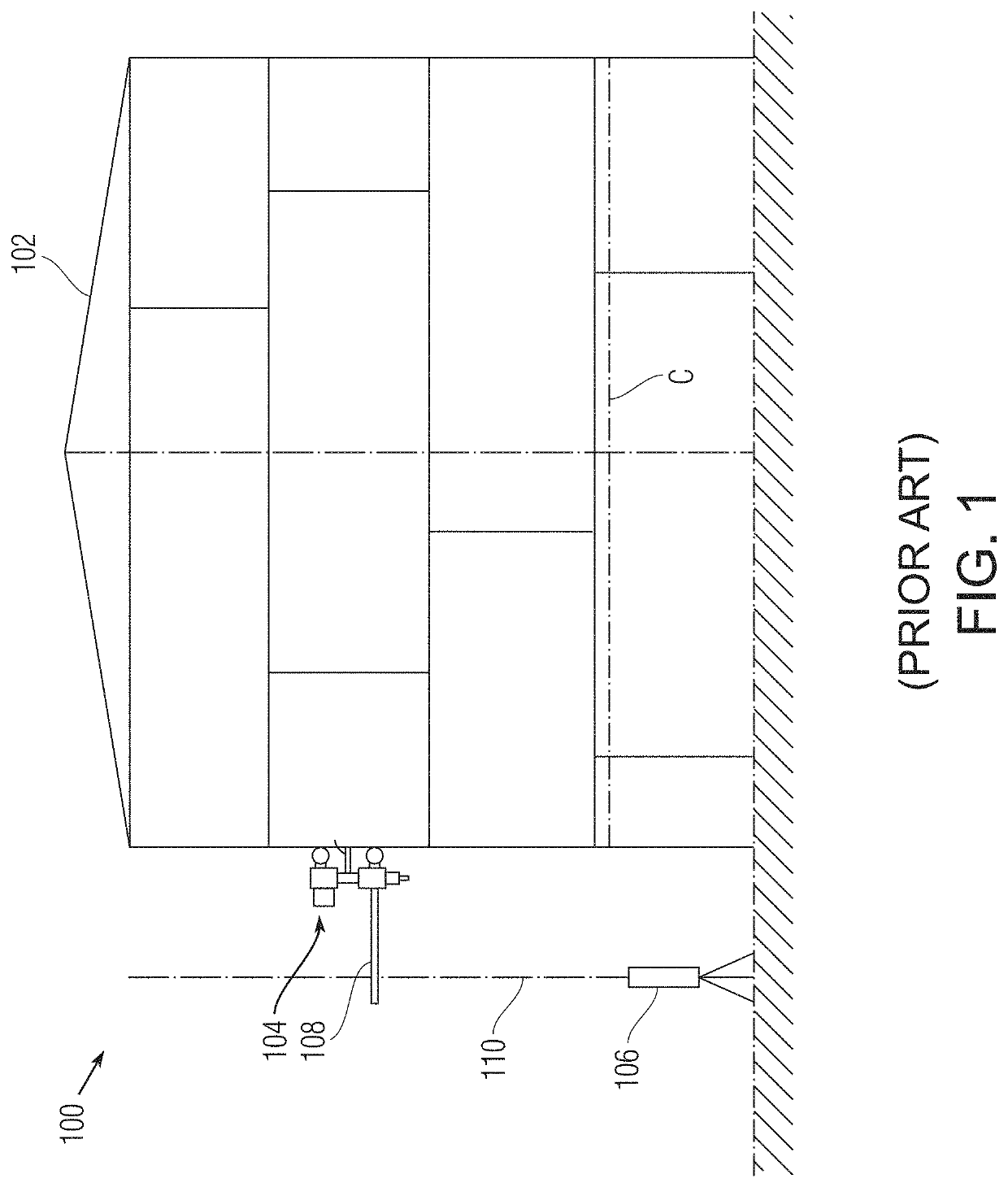

Rapid measuring mechanism of size of vehicle compartment and construction method thereof

ActiveCN106197277ASimple designEasy to operateUsing optical meansVolumetric dimension measurementsLaser scanningEngineering

The invention discloses a rapid measuring mechanism of the size of a vehicle compartment and a construction method thereof. The measuring mechanism comprises a fixing pier, a measuring control box and two rows of parallel and symmetric stand columns. The fixing pier comprises an embedded part and a positioning column arranged in the center of the embedded part. The positioning column and the embedded part are poured by cement concrete to form the fixing pier. The bottom ends of the stand columns are vertically fixed to the fixing pier. The inner sides of the top ends of every two adjacent stand columns on each row are sequentially connected and fixed through a first groove-type linear guide rail and a second groove-type linear guide rail. A walking mechanism is perpendicularly arranged between the first groove-type linear guide rail and the second groove-type linear guide rail. A first laser scanner is installed below the walking mechanism and is in communication connection with the measuring control box installed on the base through a data line. The mechanism can rapidly measure the size of goods inside the vehicle compartment, and is small in measured error and convenient to construct.

Owner:GUANGXI WODEKEJI TECH

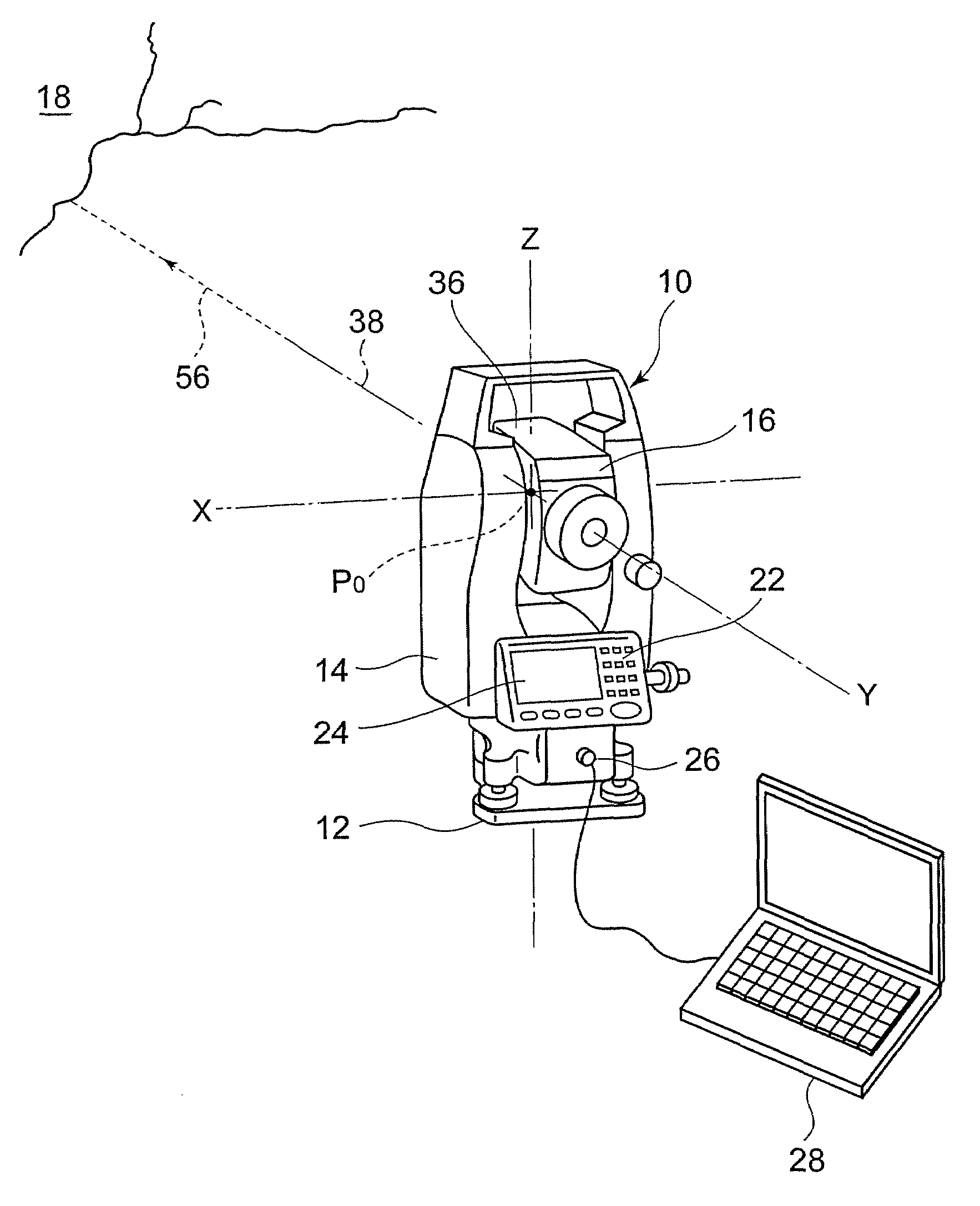

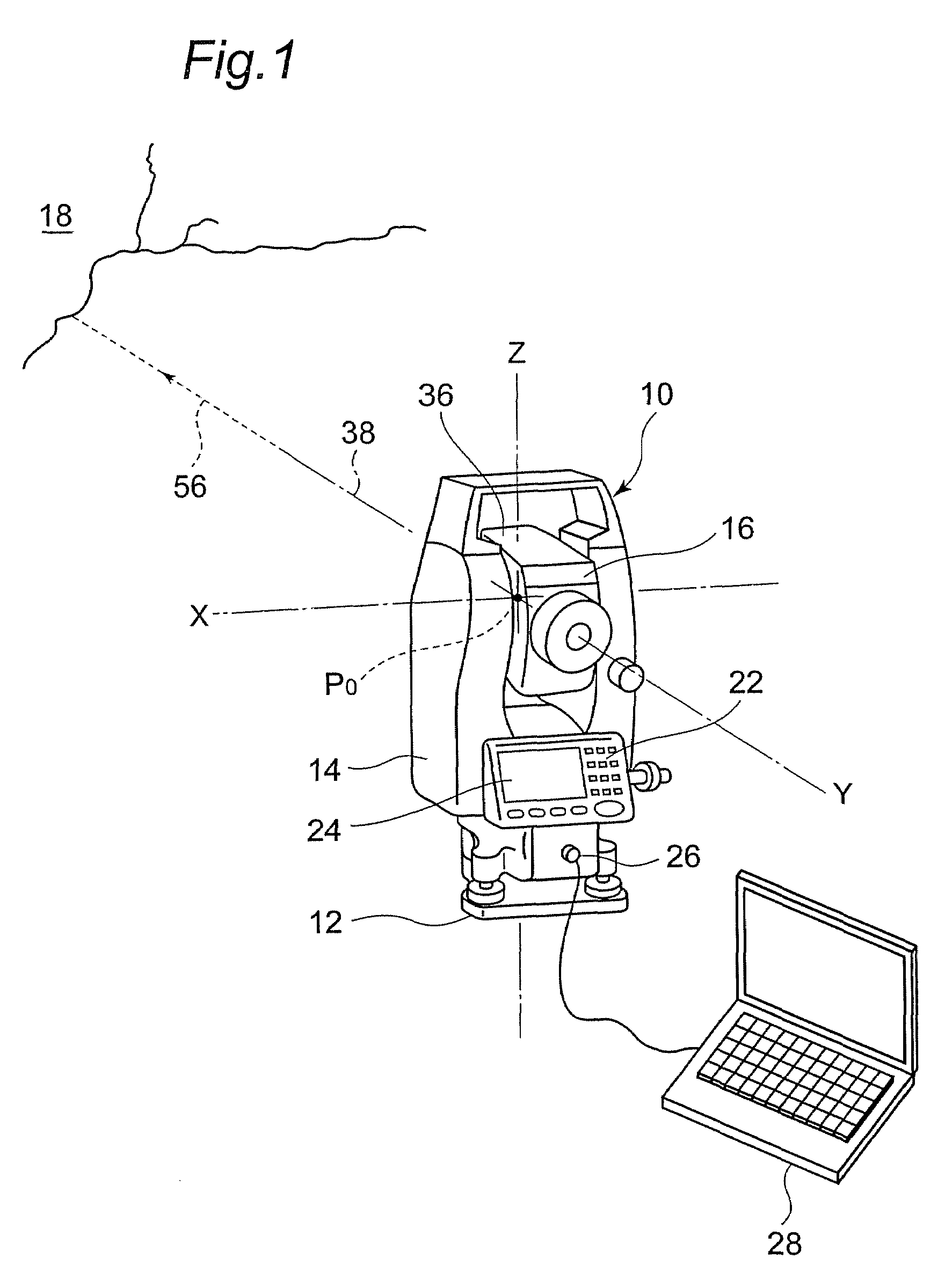

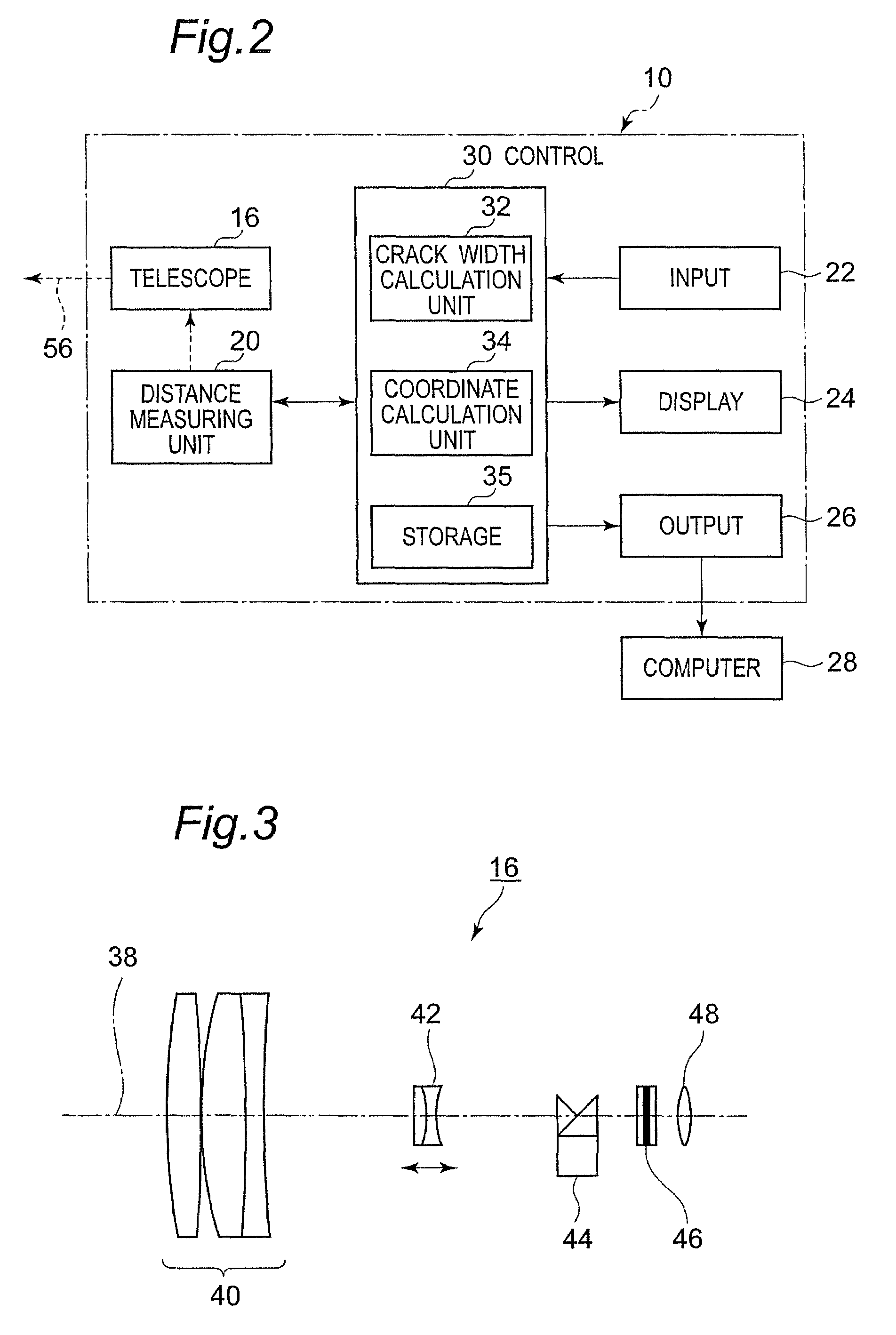

Optical device, and method of measuring the dimension of object using optical device

A device and a method for measuring the sizes of a remote object, for example, concrete crack, without using a high-place work vehicle or a ladder. An optical apparatus (e.g. a measuring device (10) ) used for this purpose is provided with a telescope (16) having a reticule plate (46) . The reticule plate (46) is provided with a plurality of reference scales (52) used for comparison with the size (W) of the image (C′) of an object (C) projected onto the reticule plate (46). The size of the object can be measured using the size of the object image measured with the reference scales (52) and a distance (a distance from a reference point P0 a to the object) measured with a distance measuring unit (20) of the optical apparatus.

Owner:KANSAI KOUJI SOKURYOU +1

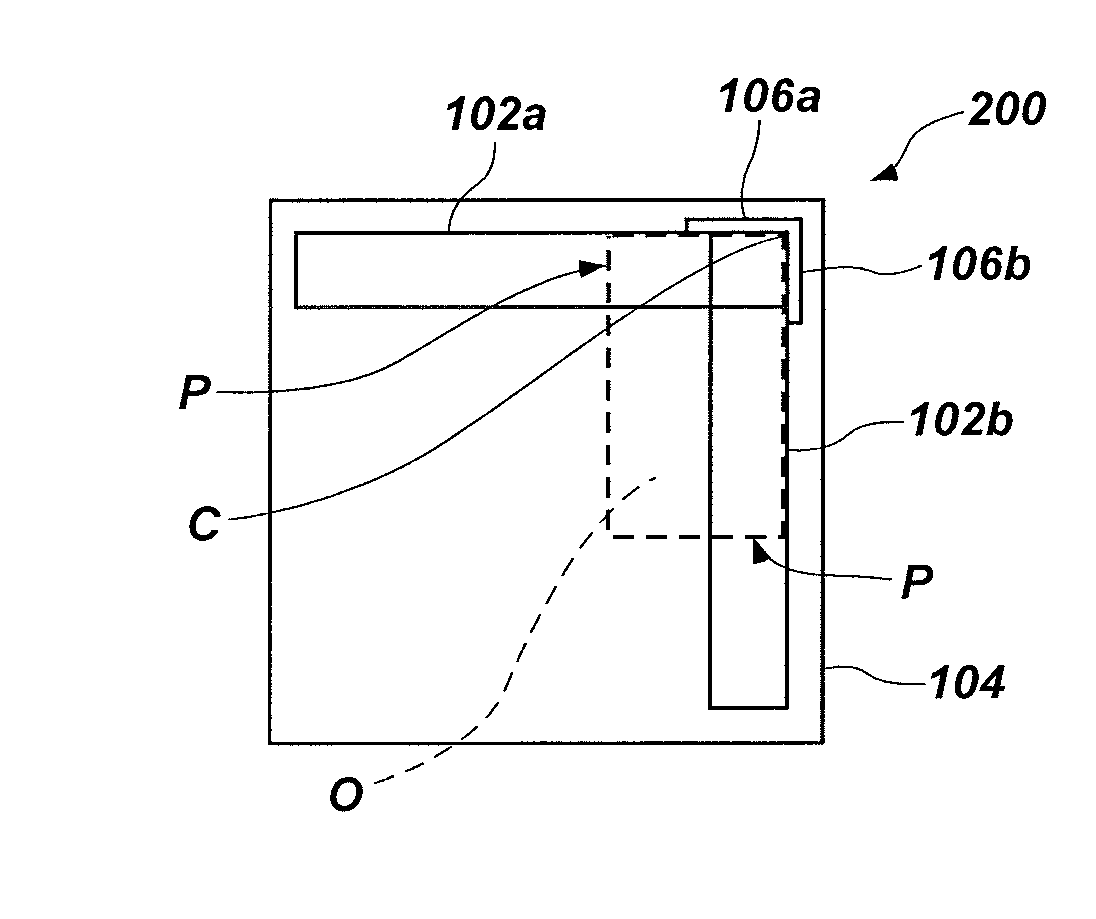

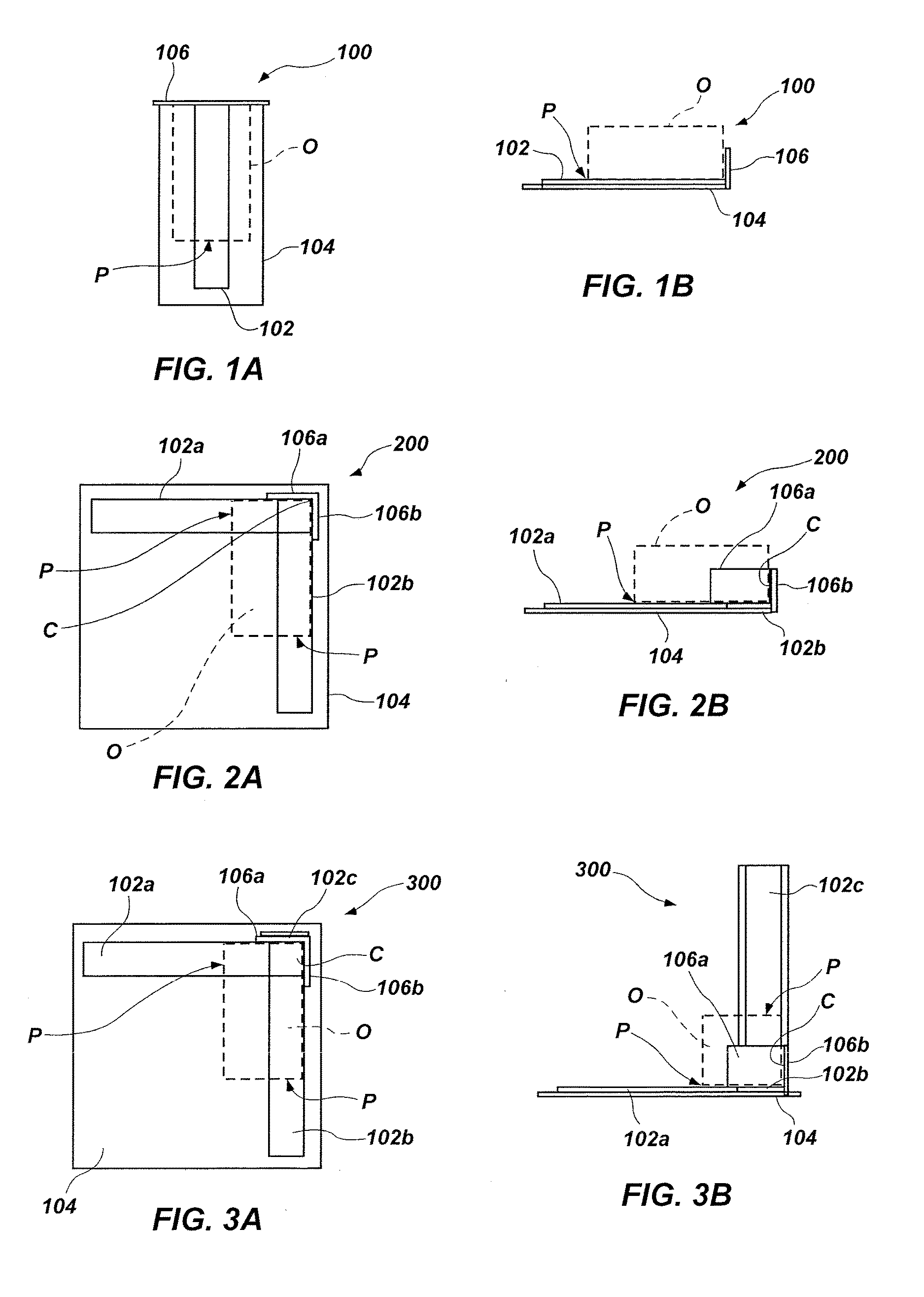

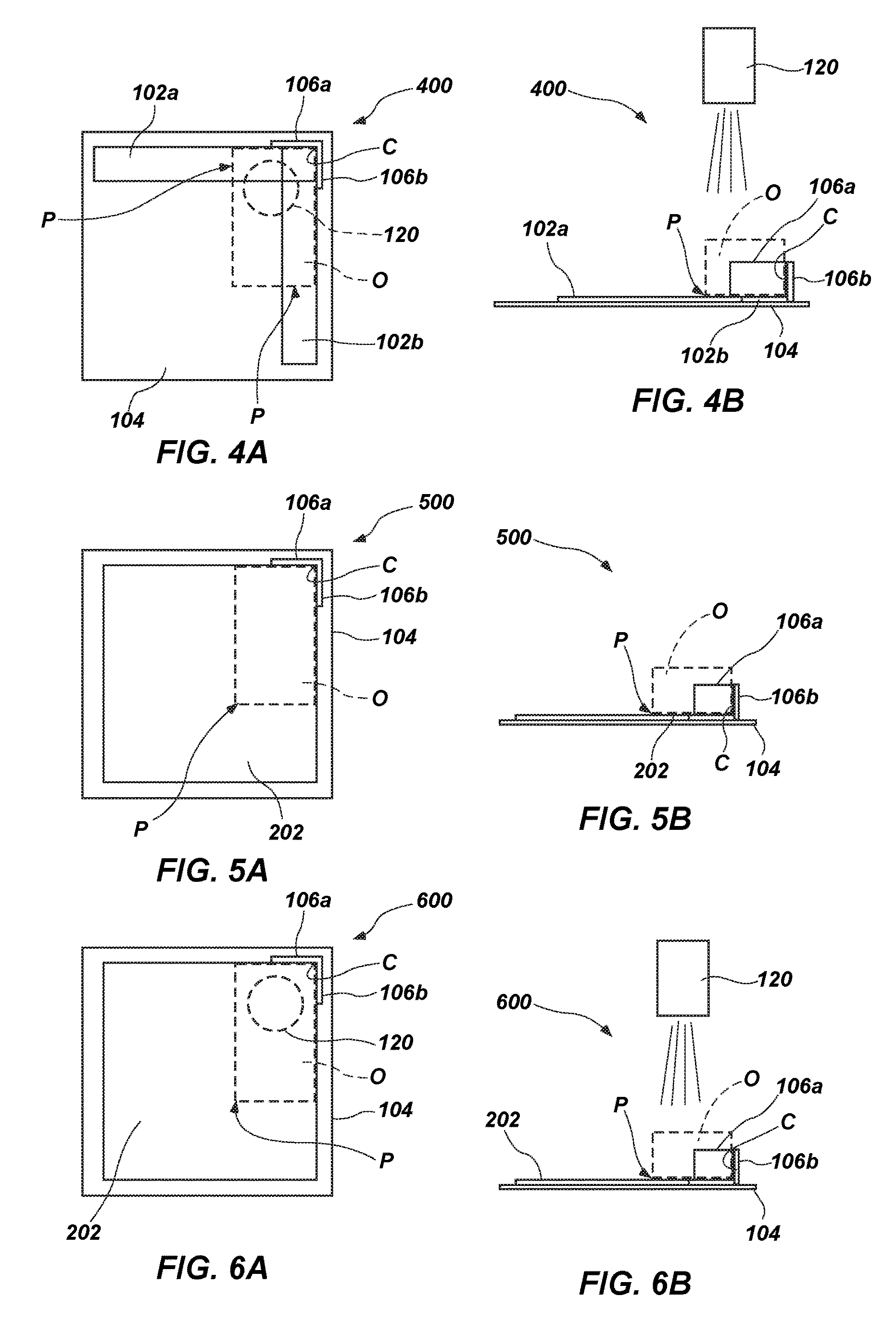

Object dimensioning apparatus, systems and related methods

ActiveUS20140373376A1Mechanical counters/curvatures measurementsUsing electrical meansComputer scienceCorrelation method

Owner:QUANTRONIX

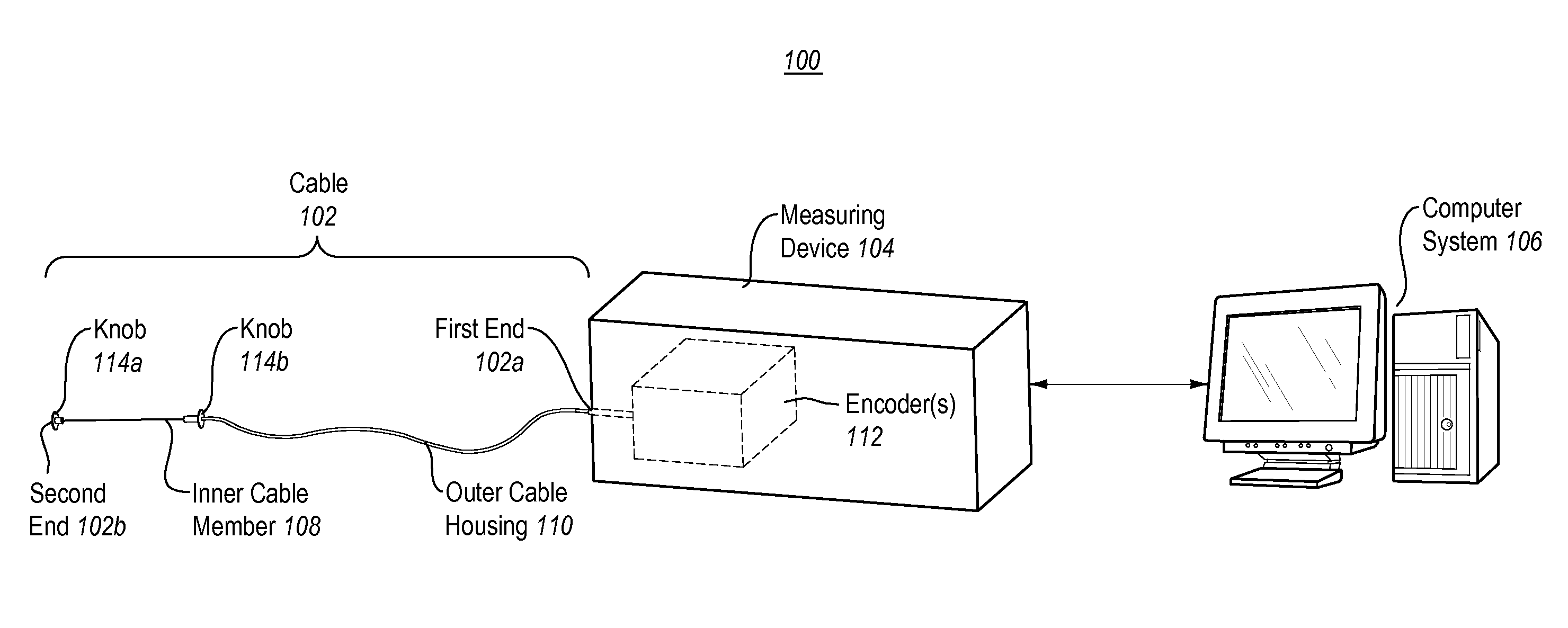

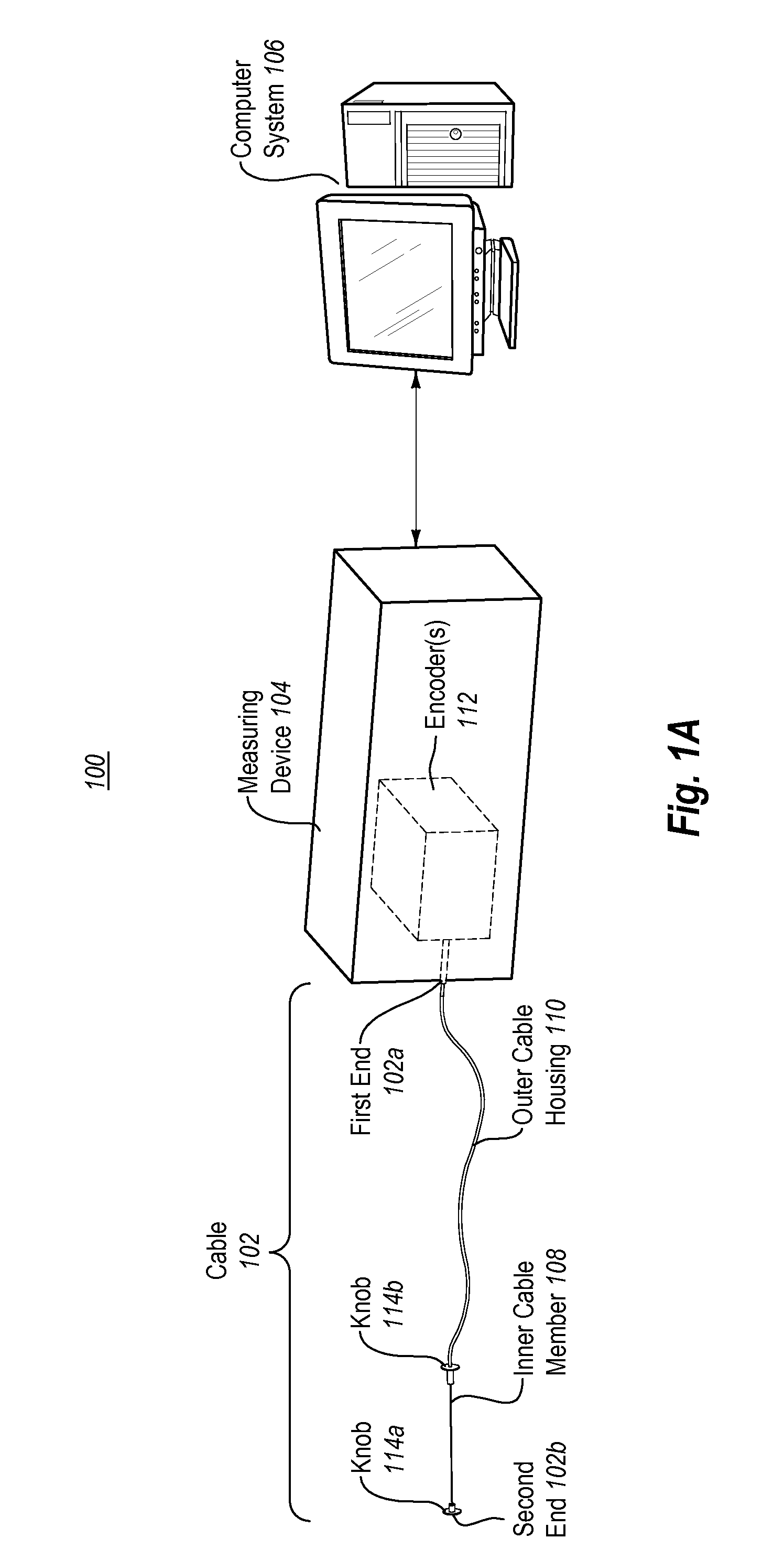

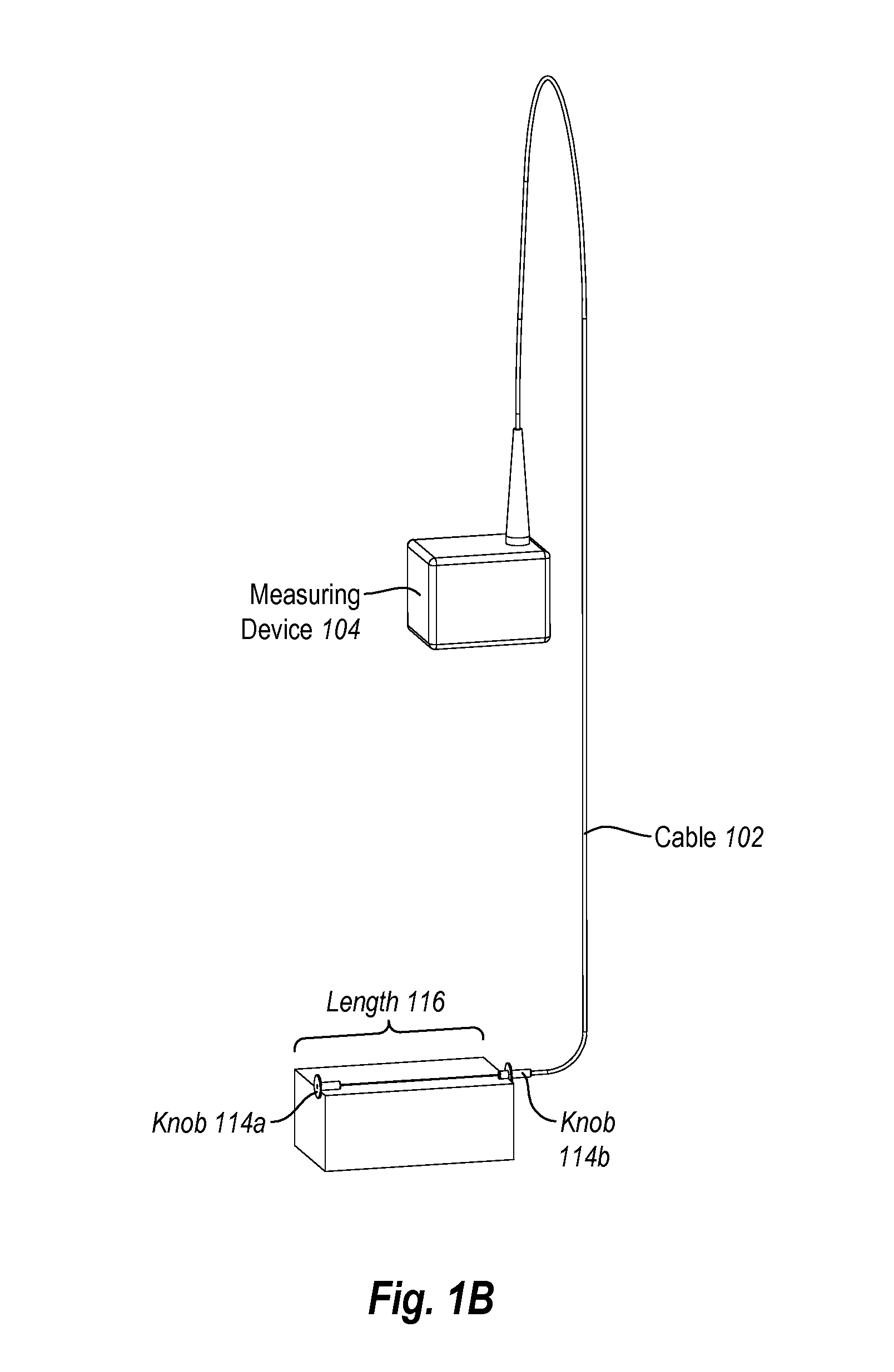

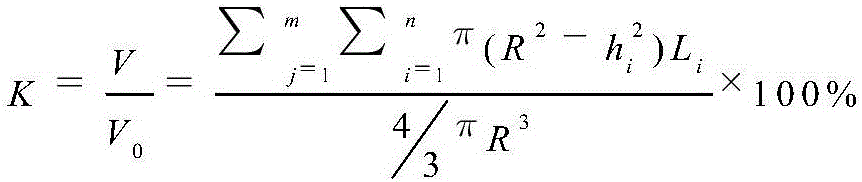

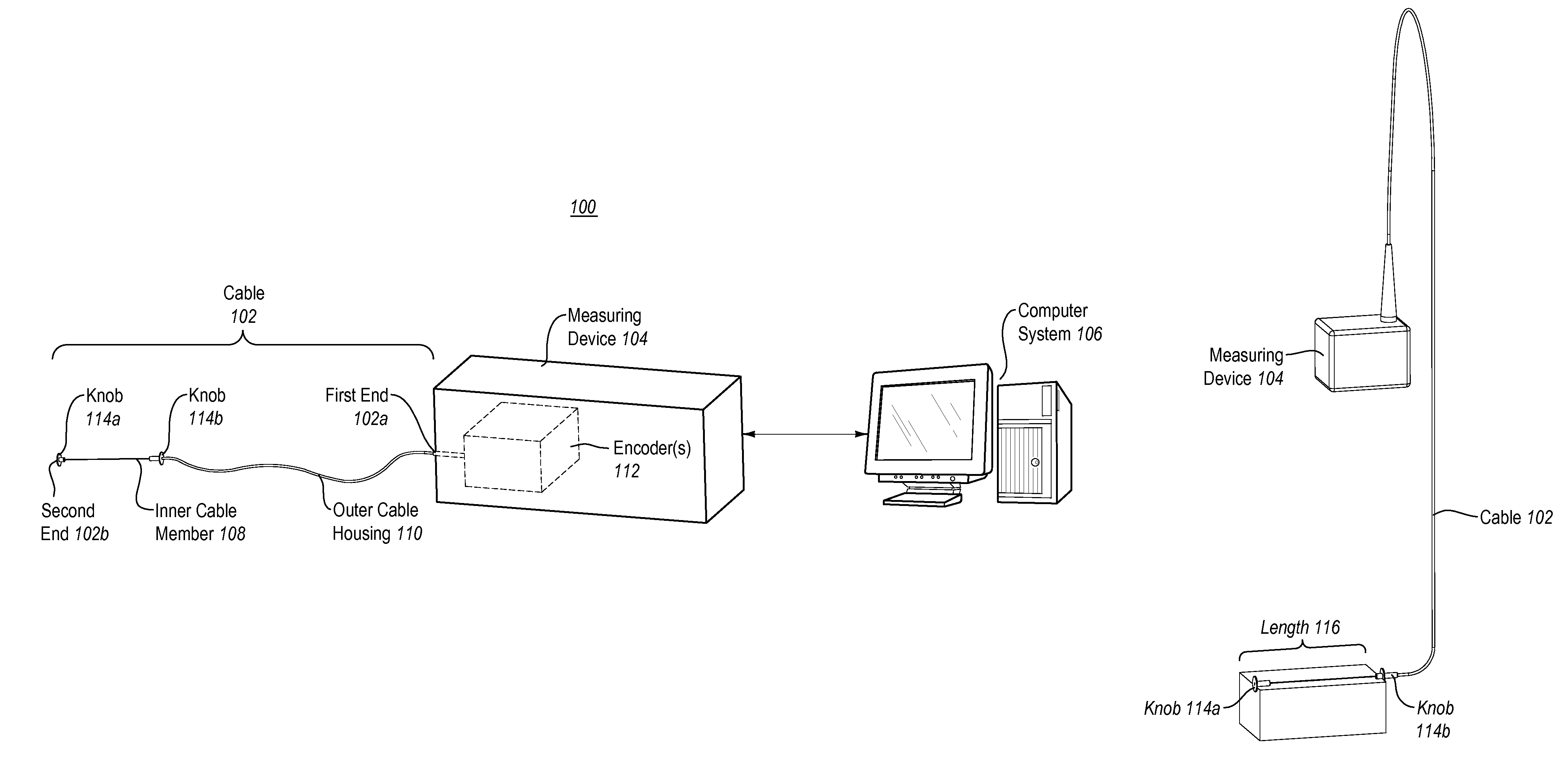

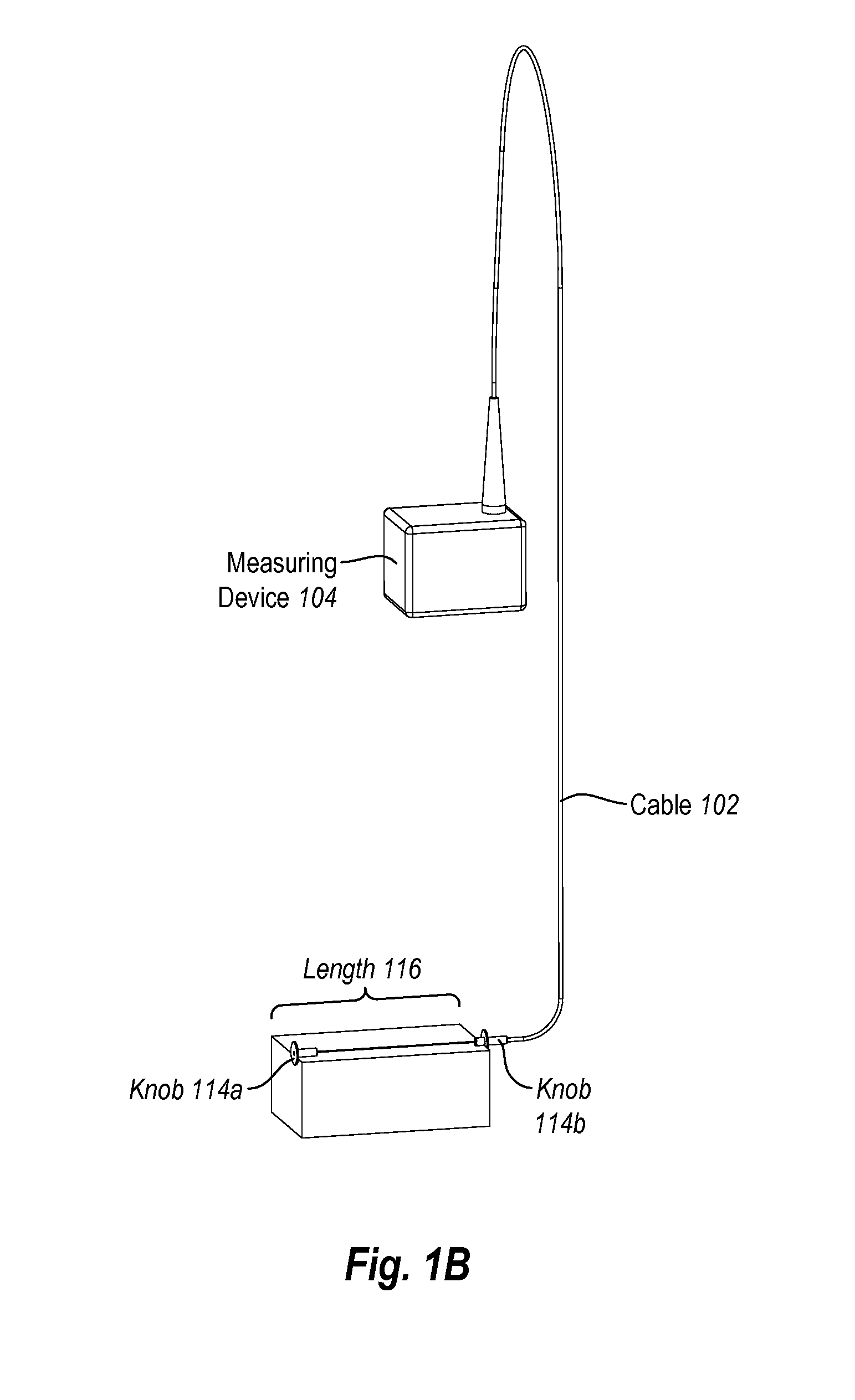

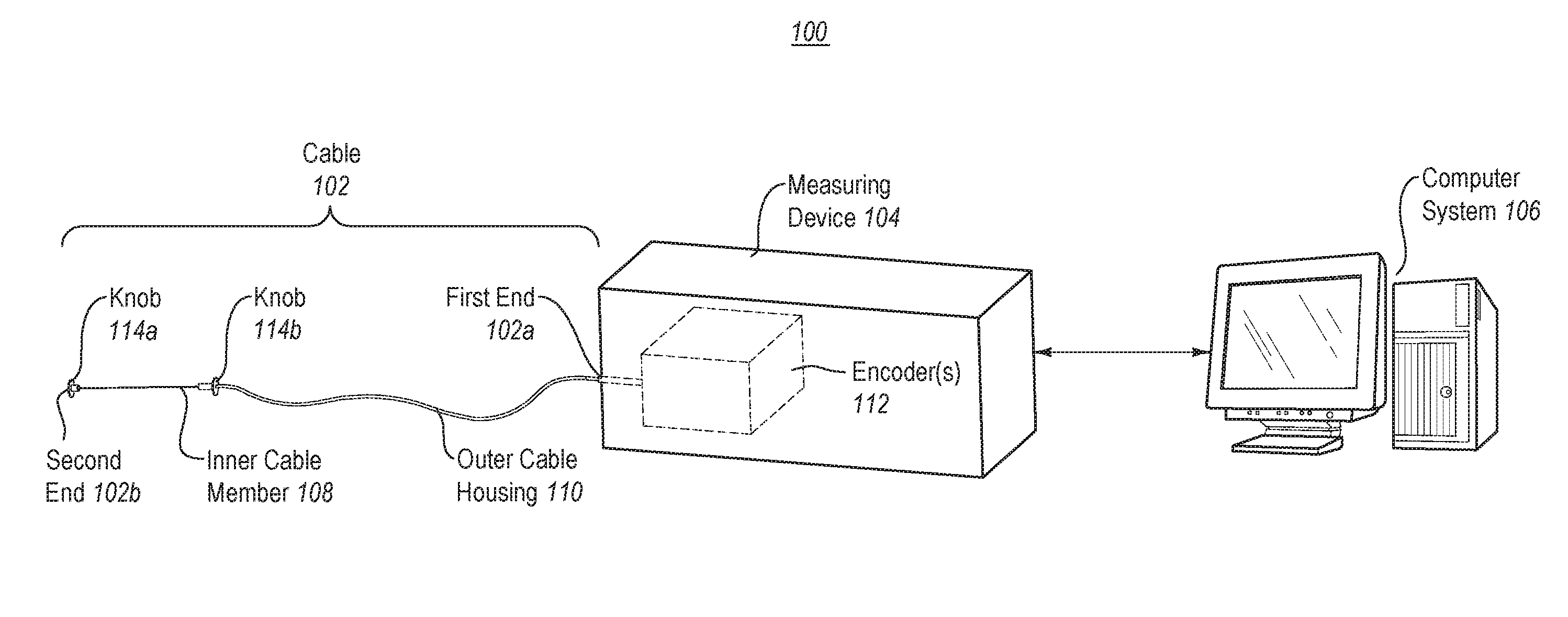

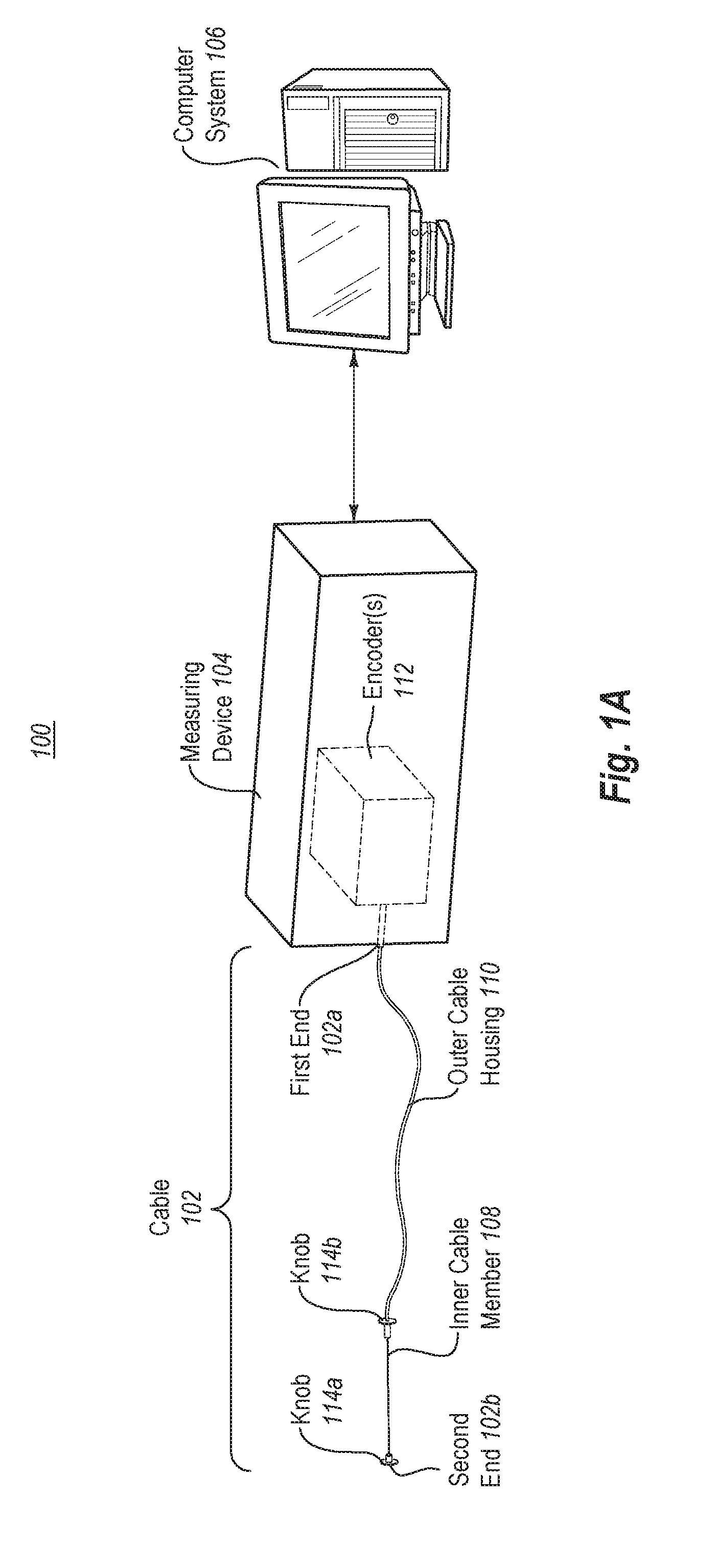

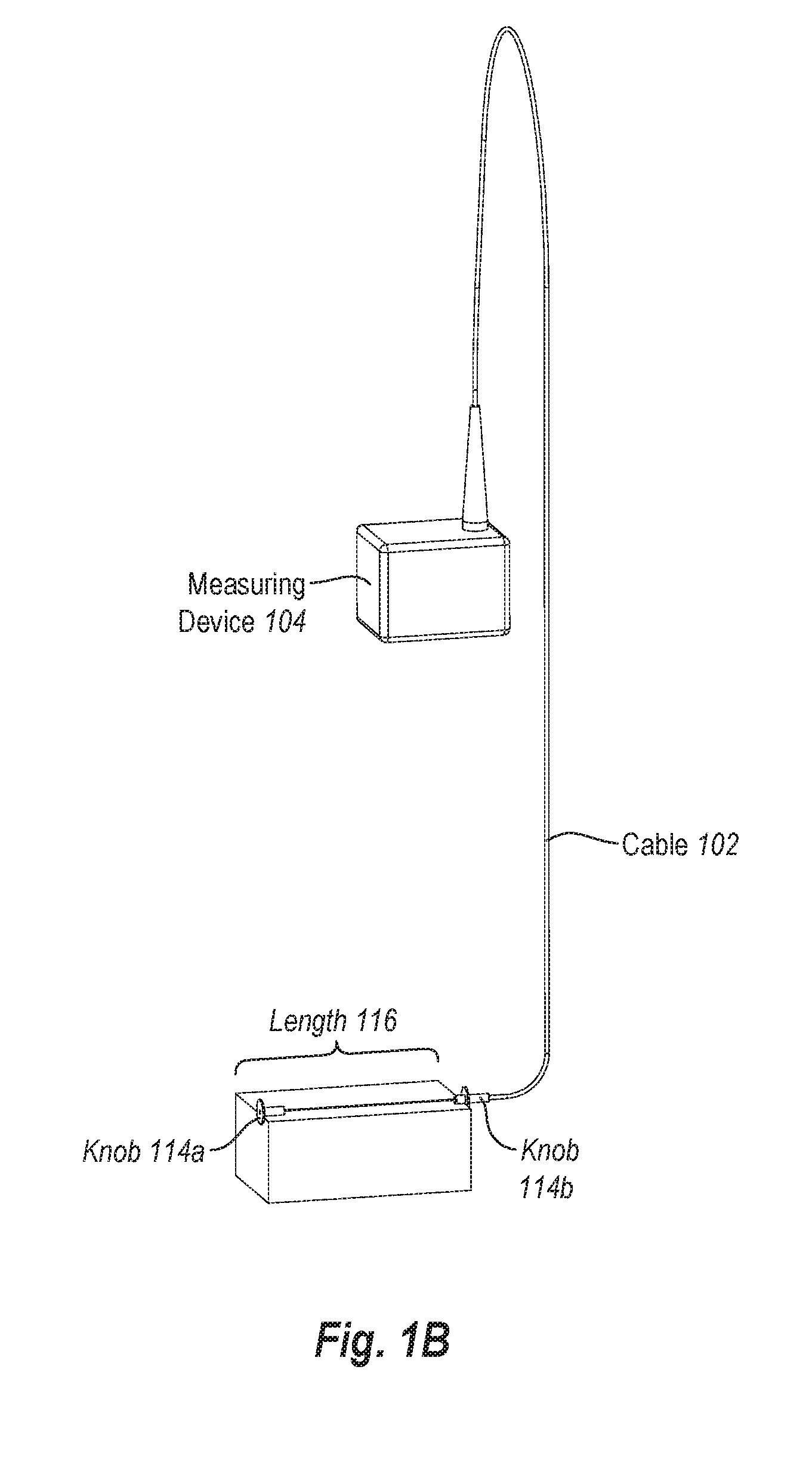

Cable-based measuring system

ActiveUS20150077765A1Length measurement chainsUsing electrical meansMeasurement deviceComputerized system

The present invention extends to methods, systems, apparatus, and computer program products related to a cable-based measuring system. The cable-based measuring system includes a cable, comprising an inner cable member configured to move linearly within an outer cable housing. The measuring system also includes a measuring device configured to generate measurement information regarding movement of the inner cable member relative to the outer cable housing using one or more encoders. A computer system receives the measurement information from the measuring device. The measurement information indicates length as a function of time, and represents three orthogonal dimensional measurements of a three-dimensional object. Based on the measurement information, the computer system identifies a length of each dimensional measurement, including a length, a width, and a height of the three-dimensional object. The computer system then initiates creation of a box template sized to accommodate the three-dimensional object and / or updates a database.

Owner:PACKSIZE

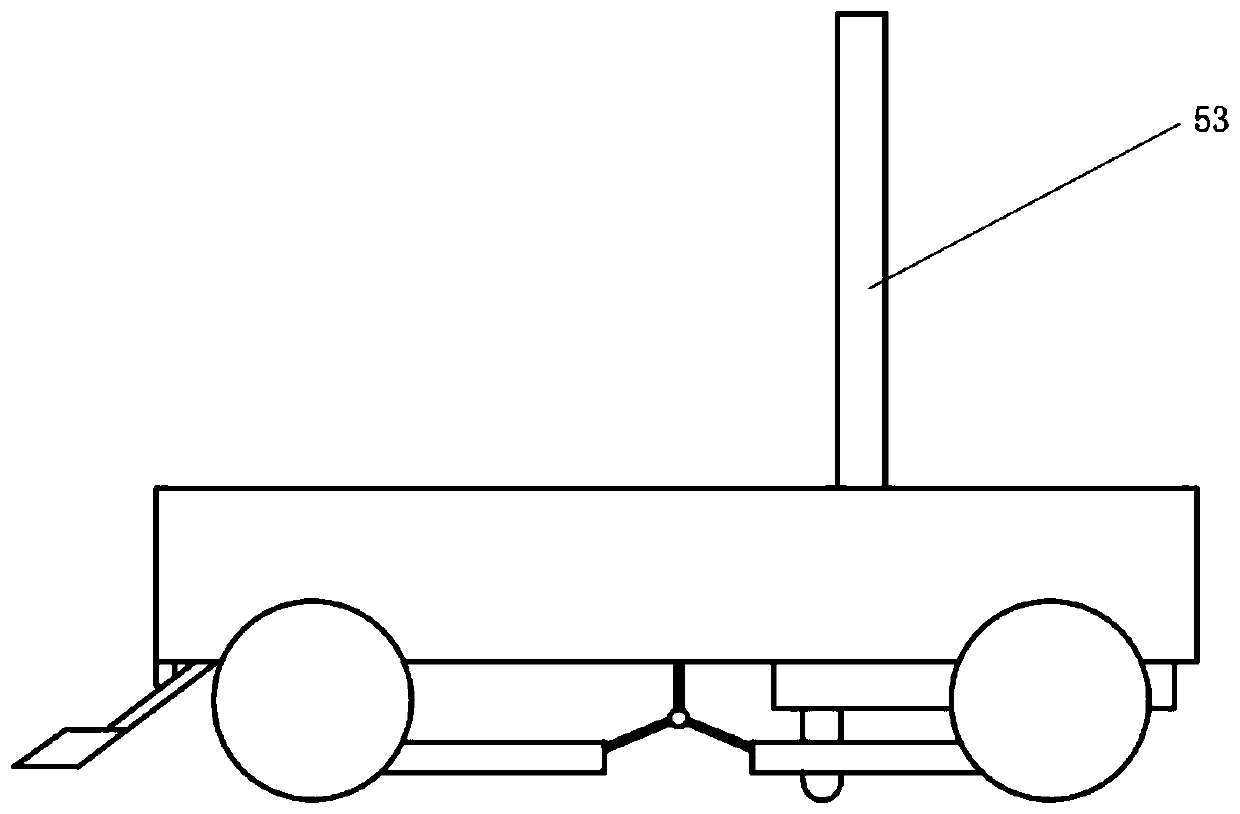

Wall-climbing robot used for capacity verification of vertical metal tank

The invention discloses a wall-climbing robot for the capacity verification of a vertical metal tank, and belongs to the technical field of volume measurement of a large metal container. The wall-climbing robot comprises a robot body, and the robot body comprises a chassis and a housing, wherein driving wheels are arranged on two sides of the chassis. The robot body is provided with an adsorptionunit, a measuring unit, a derusting unit and a control unit. The adsorption unit comprises a plurality of magnets used for adsorbing the wall of the metal tank, and the magnets are connected into a mesh through a connector and are movably arranged at the bottom of the chassis; the measuring unit comprises a folding ruler arranged on the chassis and exposed out of the top of the housing; the derusting unit comprises a derusting bucket arranged at the front end of the robot body and a driver for driving the derusting bucket to lift up and down; and the control unit comprises a microcontroller, aposture detector, an obstacle detector, a suction detector used for detecting the adsorption force of the magnets, a distance sensor used for measuring the distance between the top of the housing andthe metal tank wall, and a communication device. According to the wall-climbing robot, the problem of leaving indentations on the surface of the metal tank is avoided and also the problem that the robot is affected by the rust on the wall of the metal tank is avoided.

Owner:ZHOUSHAN INST OF CALIBRATION & TESTING FOR QUALITY & TECHNICAL SUPERVISION +1

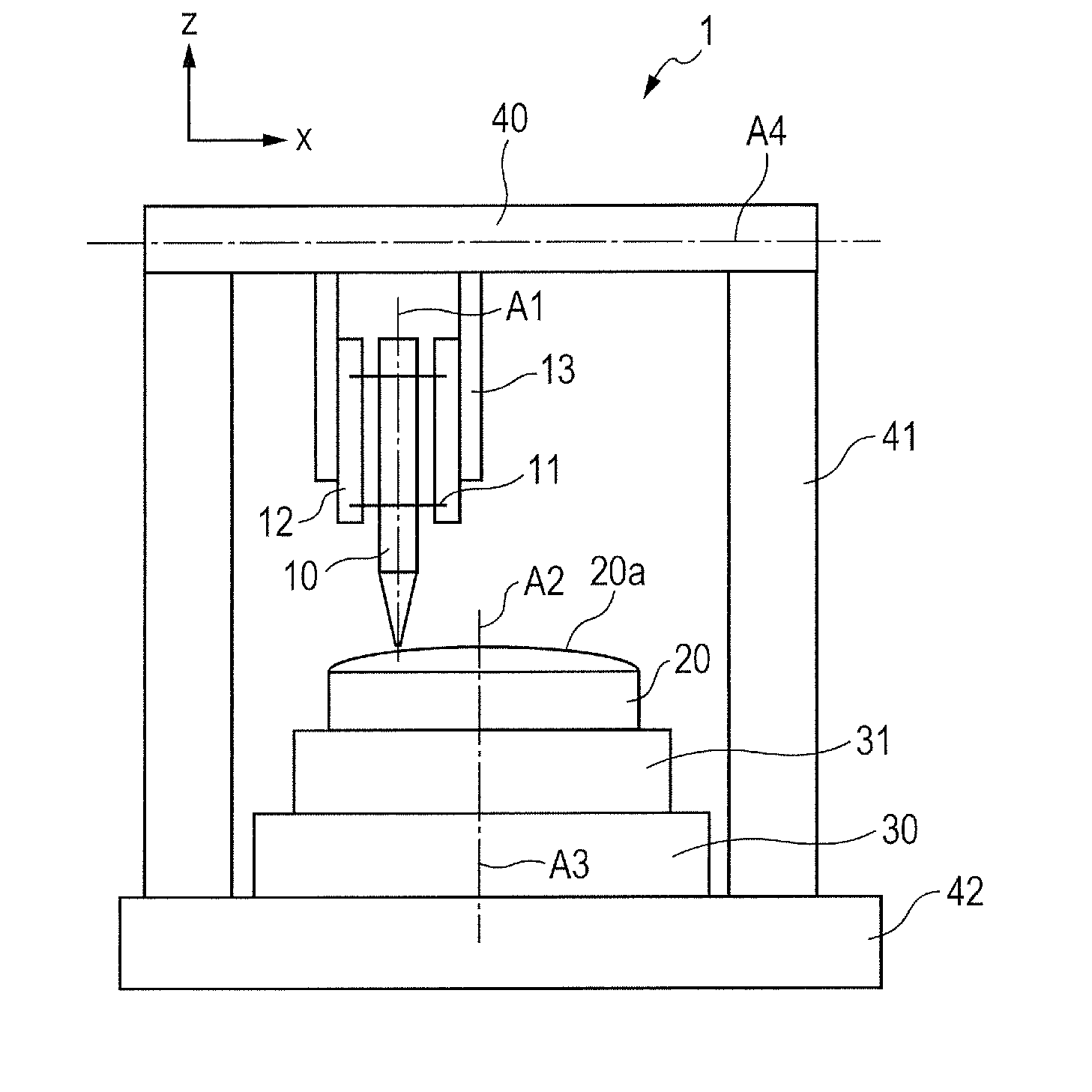

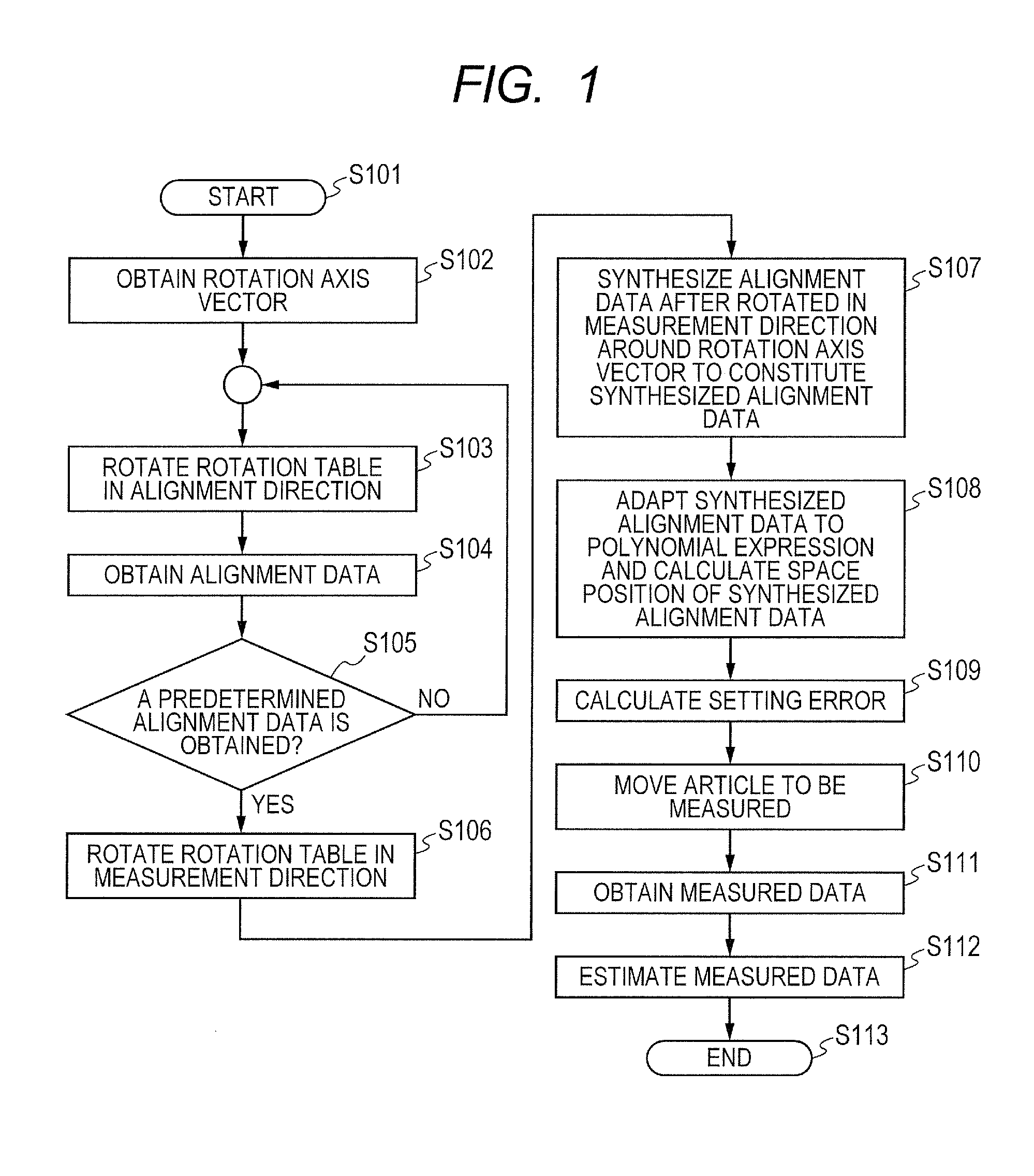

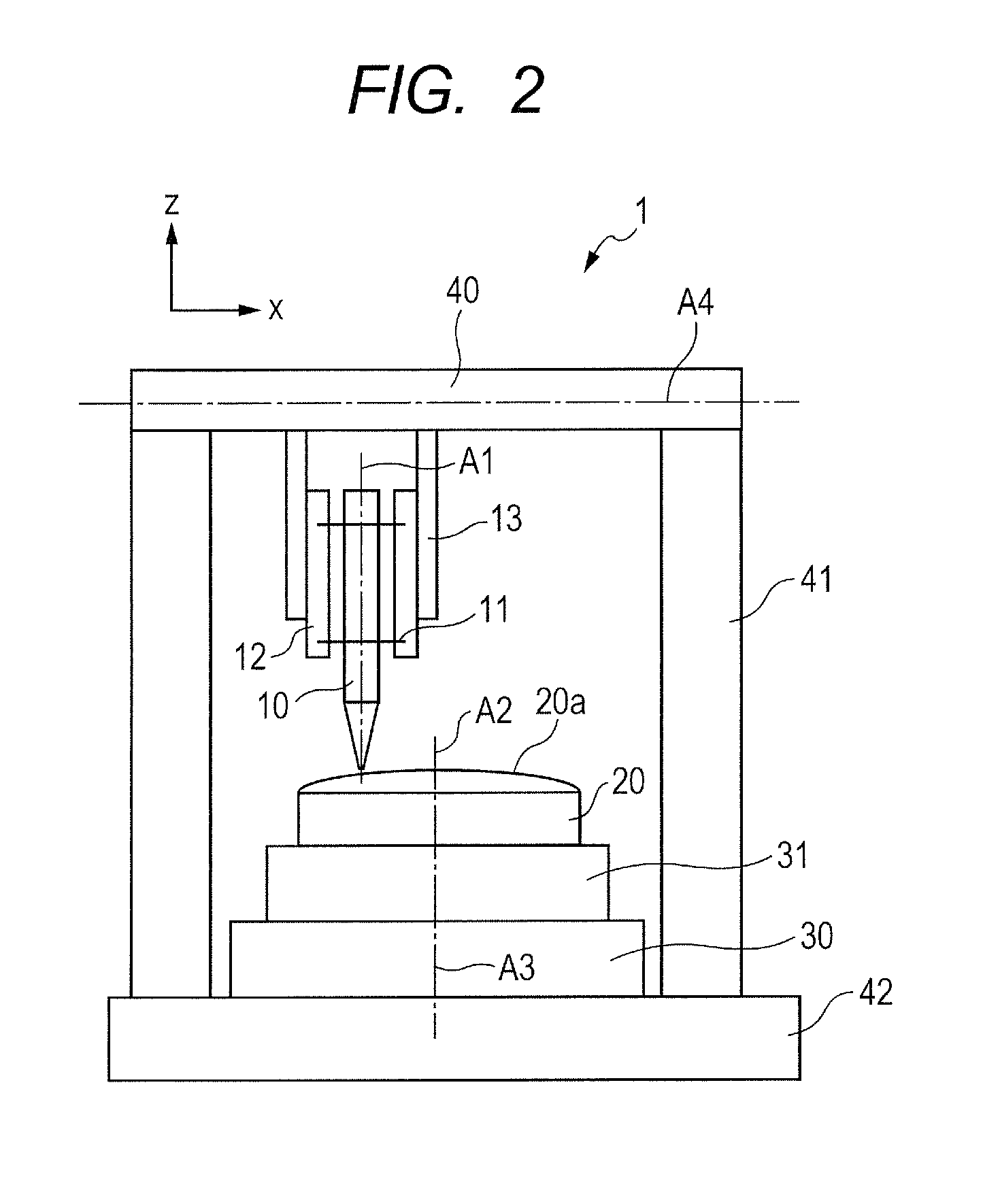

Contour shape measurement method

ActiveUS20140157564A1Reduce setting errorsAngles/taper measurementsMechanical counters/curvatures measurementsPhysicsThree dimensional data

Owner:CANON KK

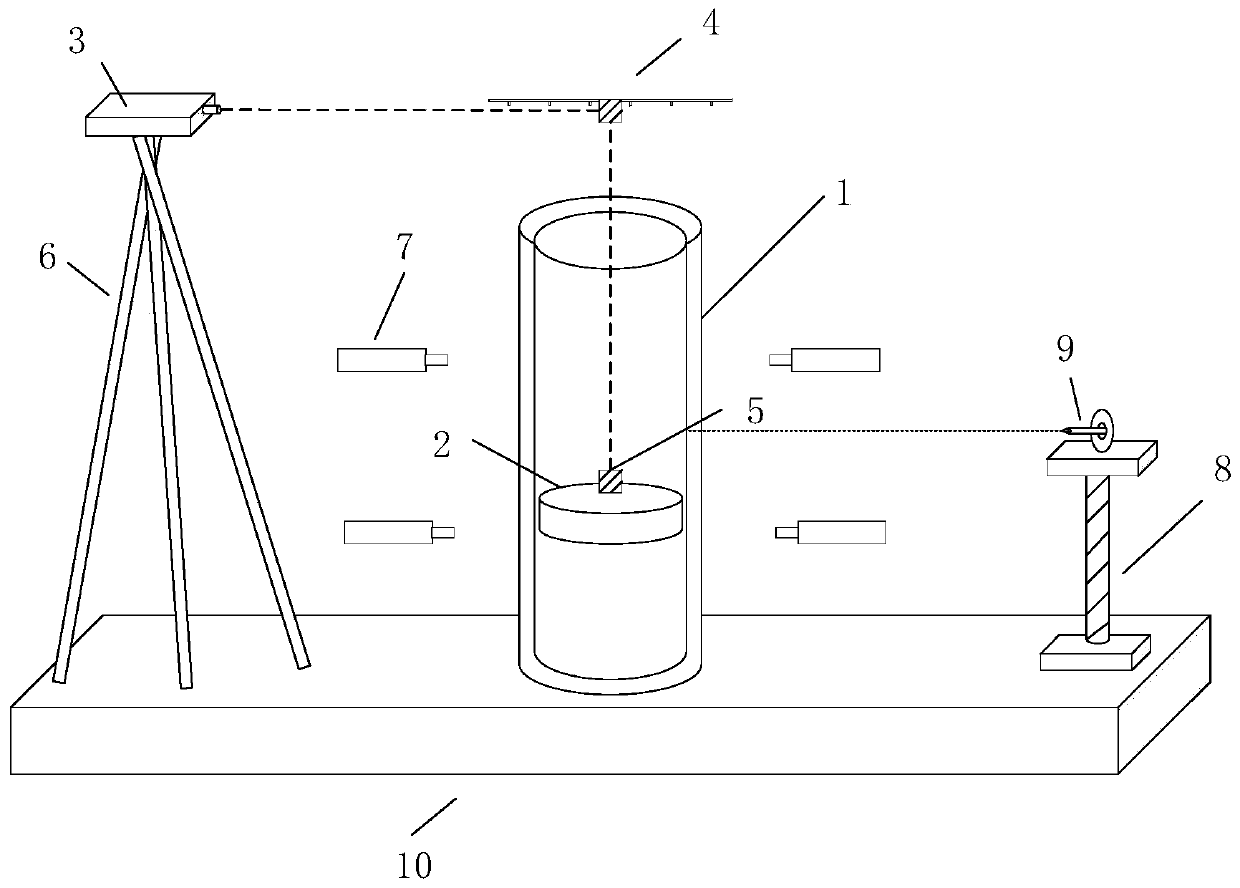

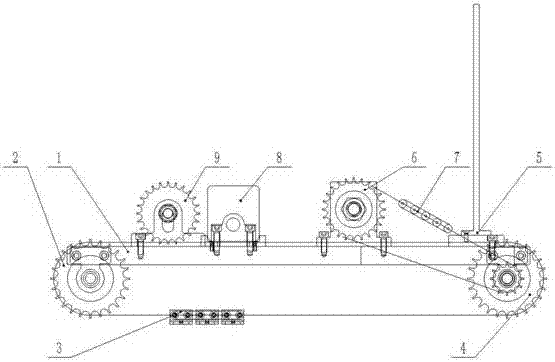

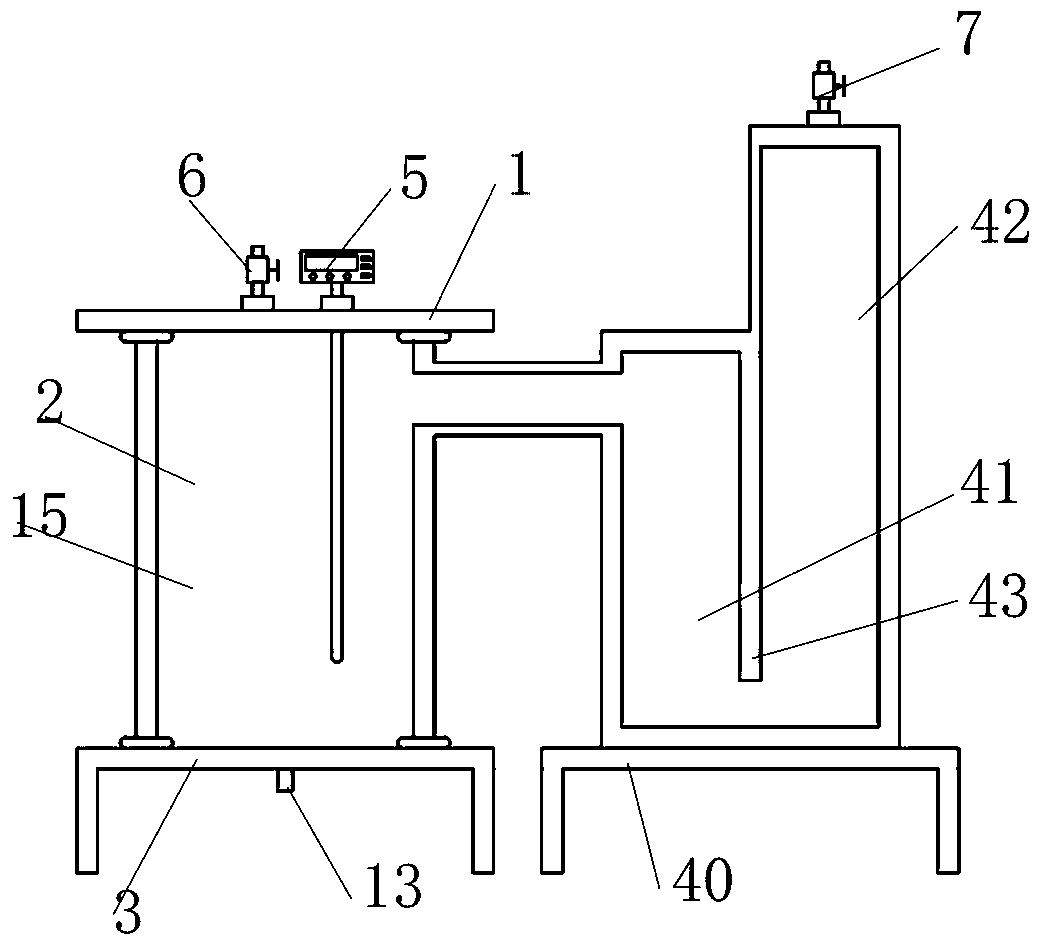

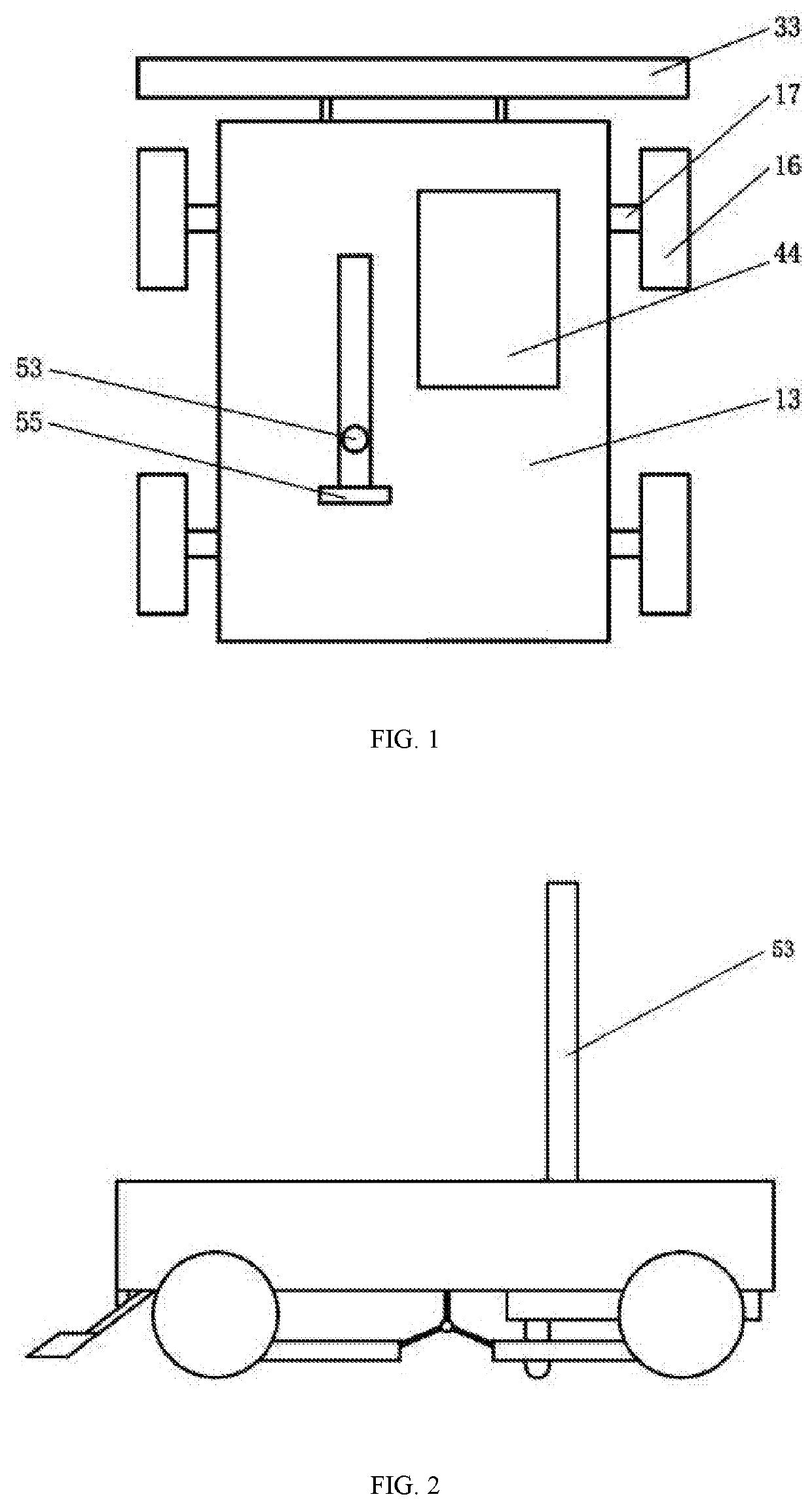

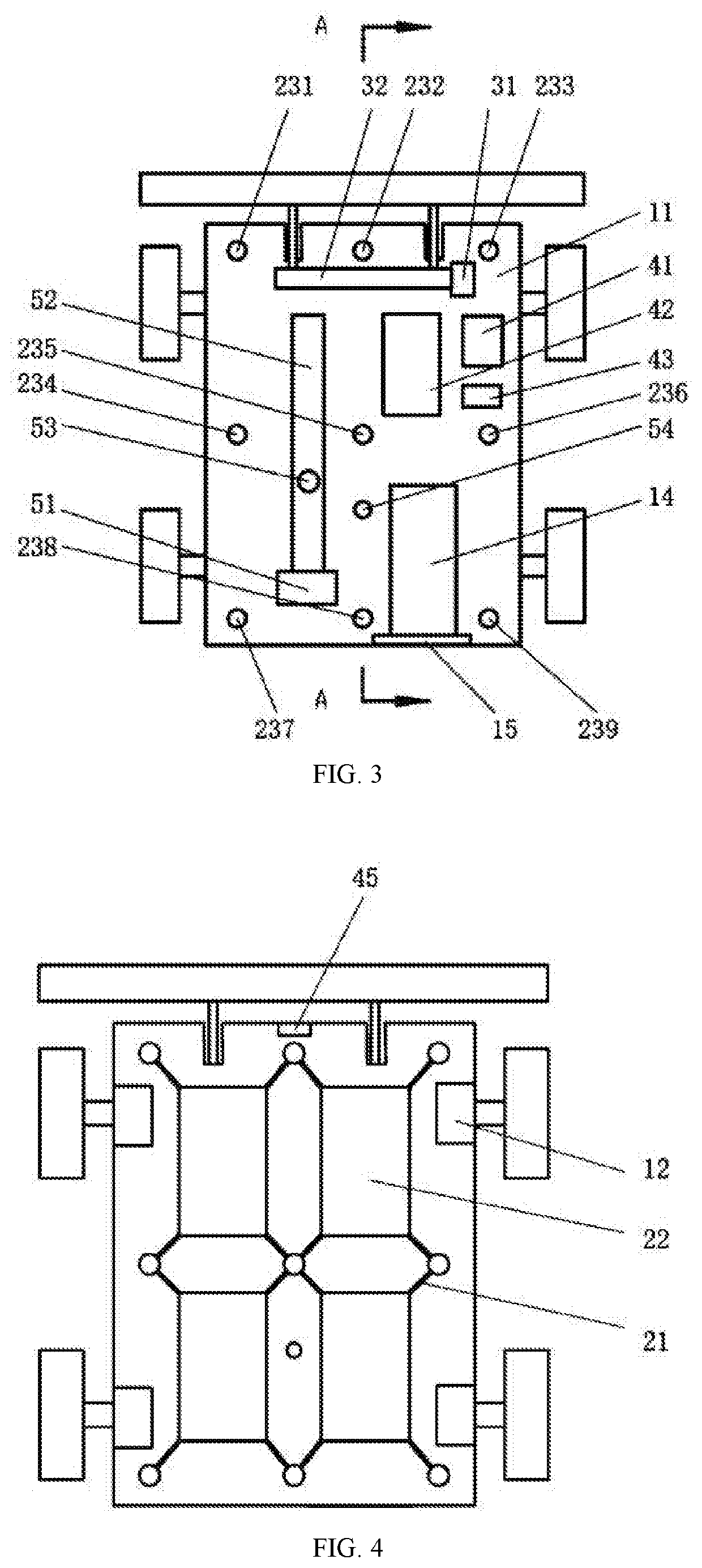

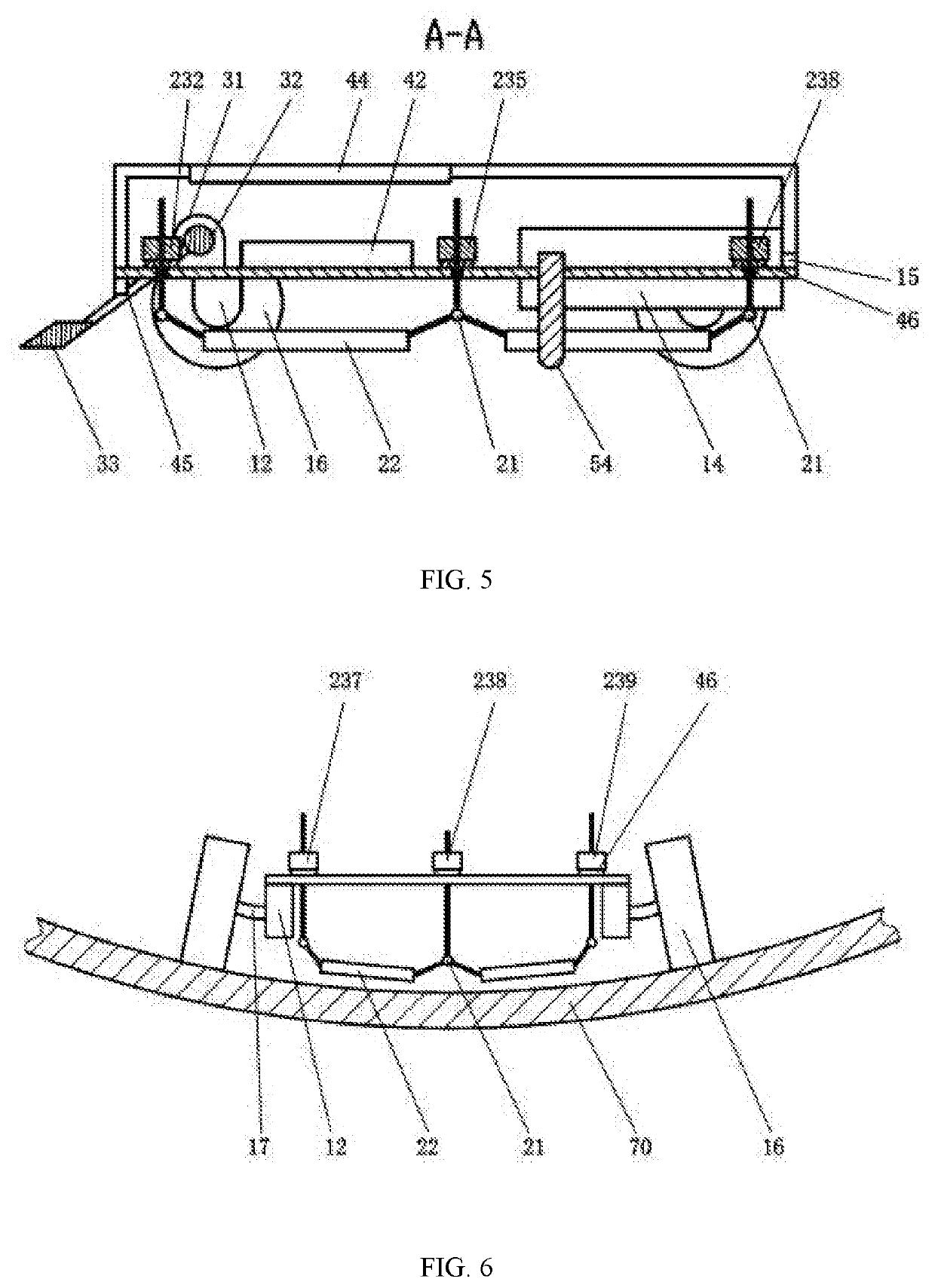

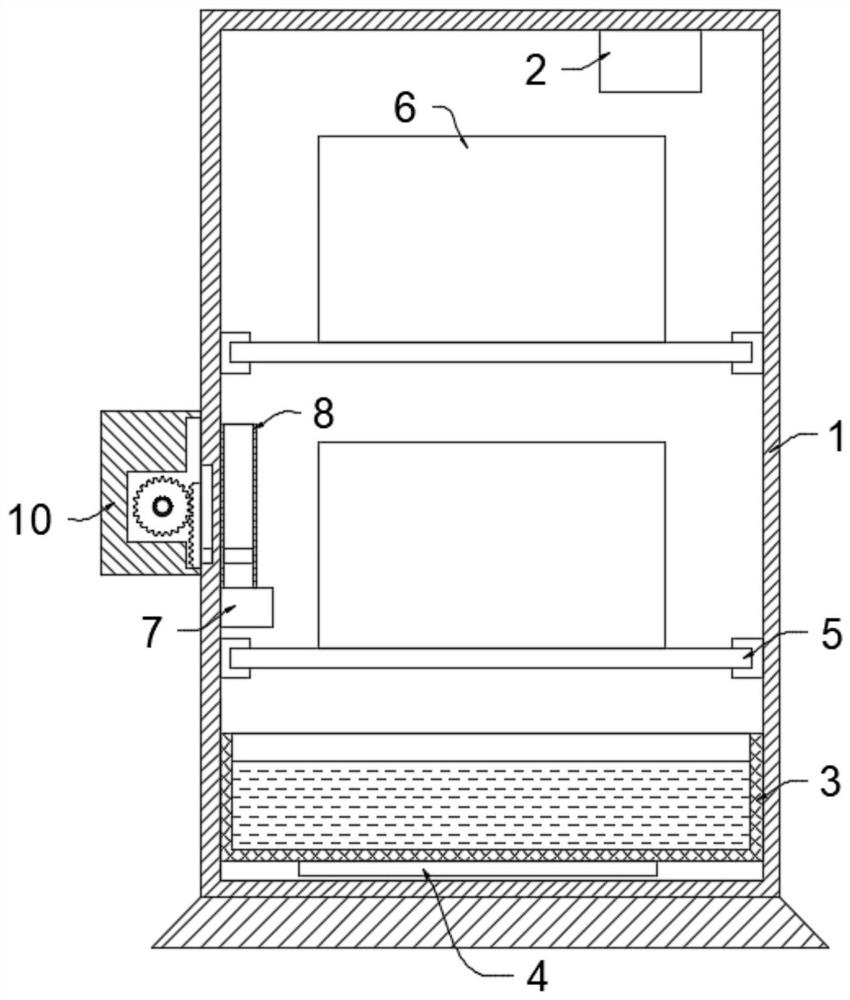

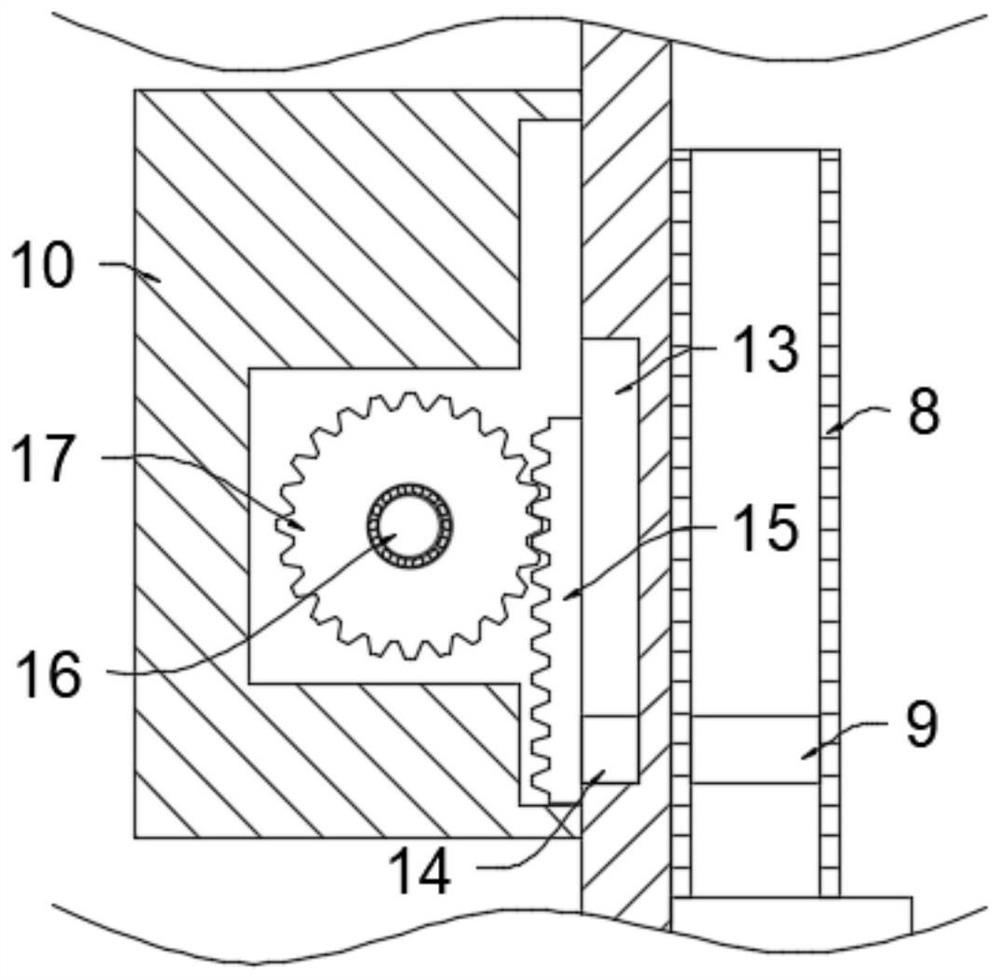

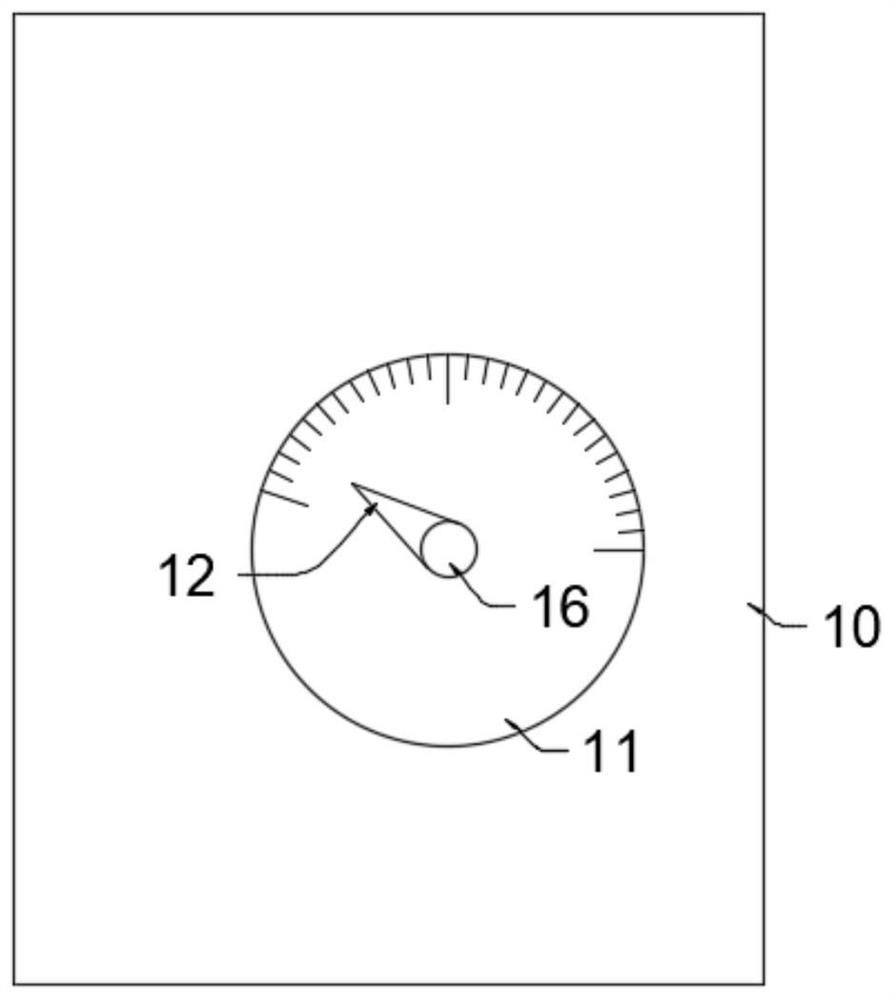

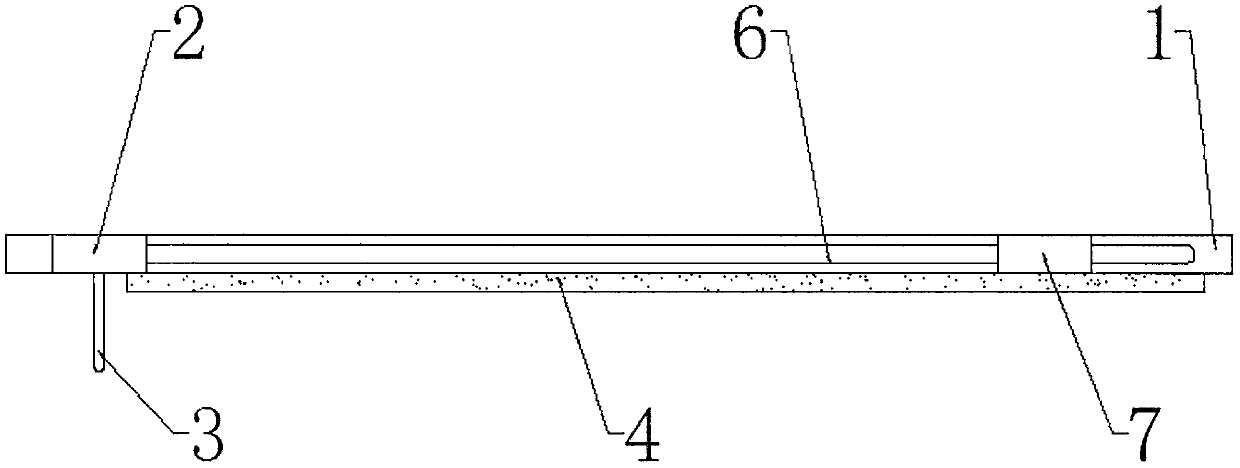

Apparatus for vertical metal can capacity measurement

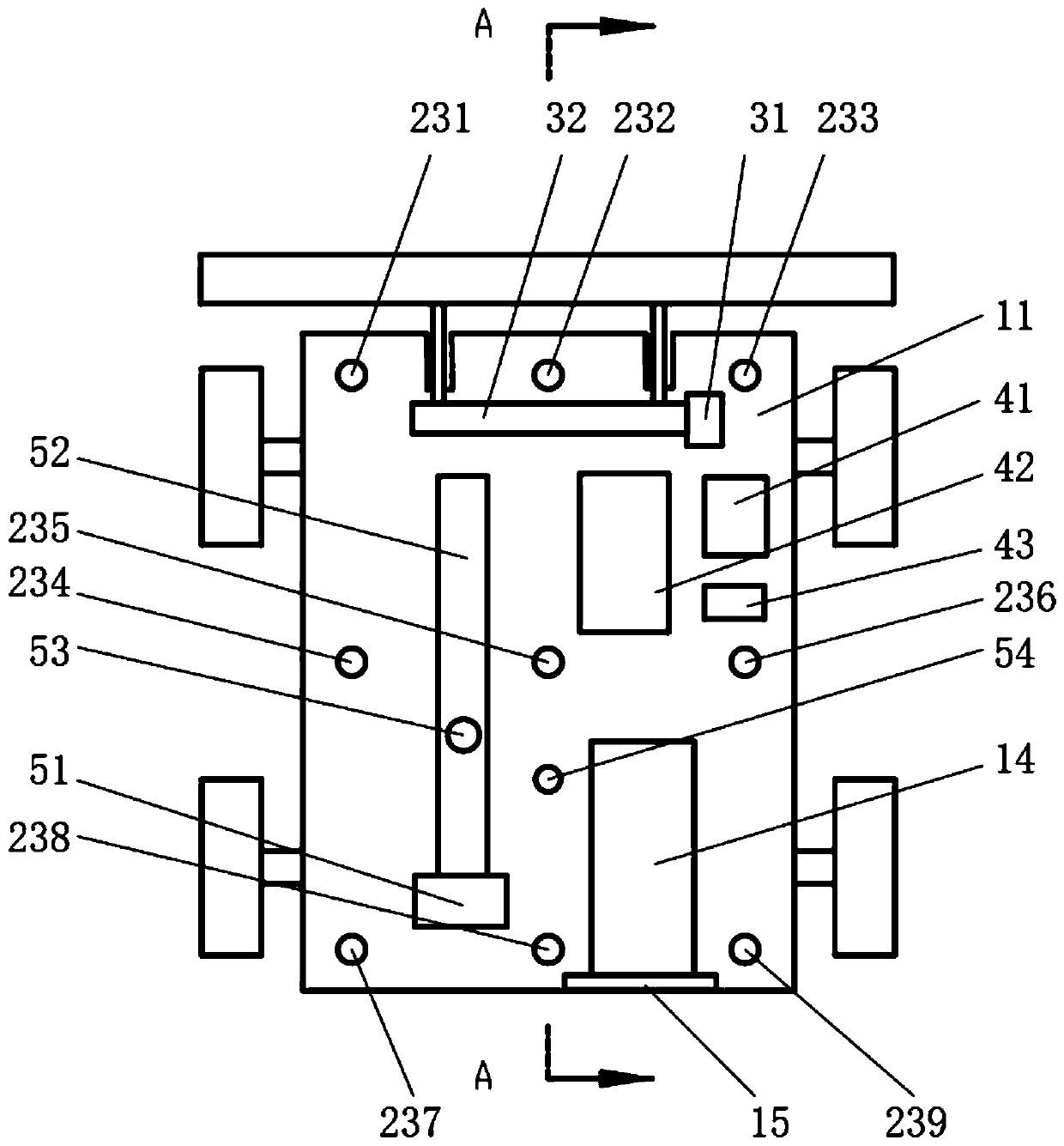

ActiveCN106949804AFully contactedAccurate measurementVolumetric dimension measurementsStructural engineeringSprocket

Provided is an apparatus for vertical metal can capacity measurement. The apparatus includes a table plate, a driven mechanism and a driving mechanism are respectively arranged at the left and right sides of the table plate, an adsorption mechanism is connected with the driven mechanism and the driving mechanism and is tensioned by a tensioning mechanism, the table plate is further provided with a sliding adjustment mechanism and a power mechanism, the power mechanism is connected with the driving mechanism via a power sprocket wheel, and the table plate nearby the driving mechanism is further provided with a scale. The apparatus works as follows: the apparatus is absorbed by the adsorption mechanism to the wall of the metal can with the capacity to be measured, and the action of the power mechanism is controlled via signals, the power mechanism drives the driving mechanism through the power sprocket wheel so that the apparatus climbs along the wall of the metal can to be measured, when the apparatus does not climb in the vertical direction, the sliding adjustment mechanism is controlled by the signals to slightly adjust the device back to the vertical trajectory, and when the apparatus reaches the measuring point, a control unit stops and observes and records the reading of the scale. The apparatus is simple in operation, can realize the continuous measurement of the wall of the vertical metal can, and is practical to use.

Owner:ZHOUSHAN INST OF CALIBRATION & TESTING FOR QUALITY & TECHNICAL SUPERVISION

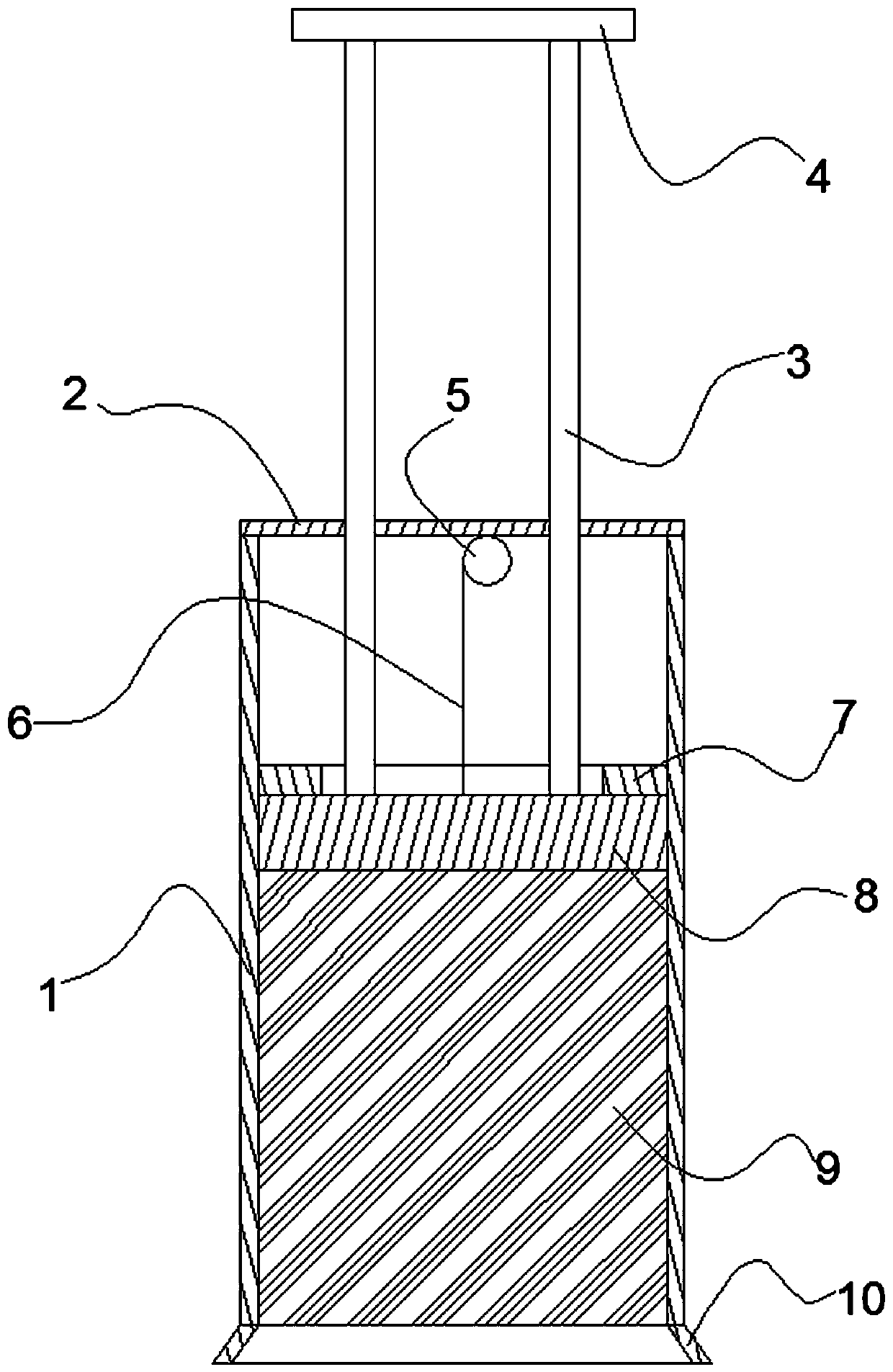

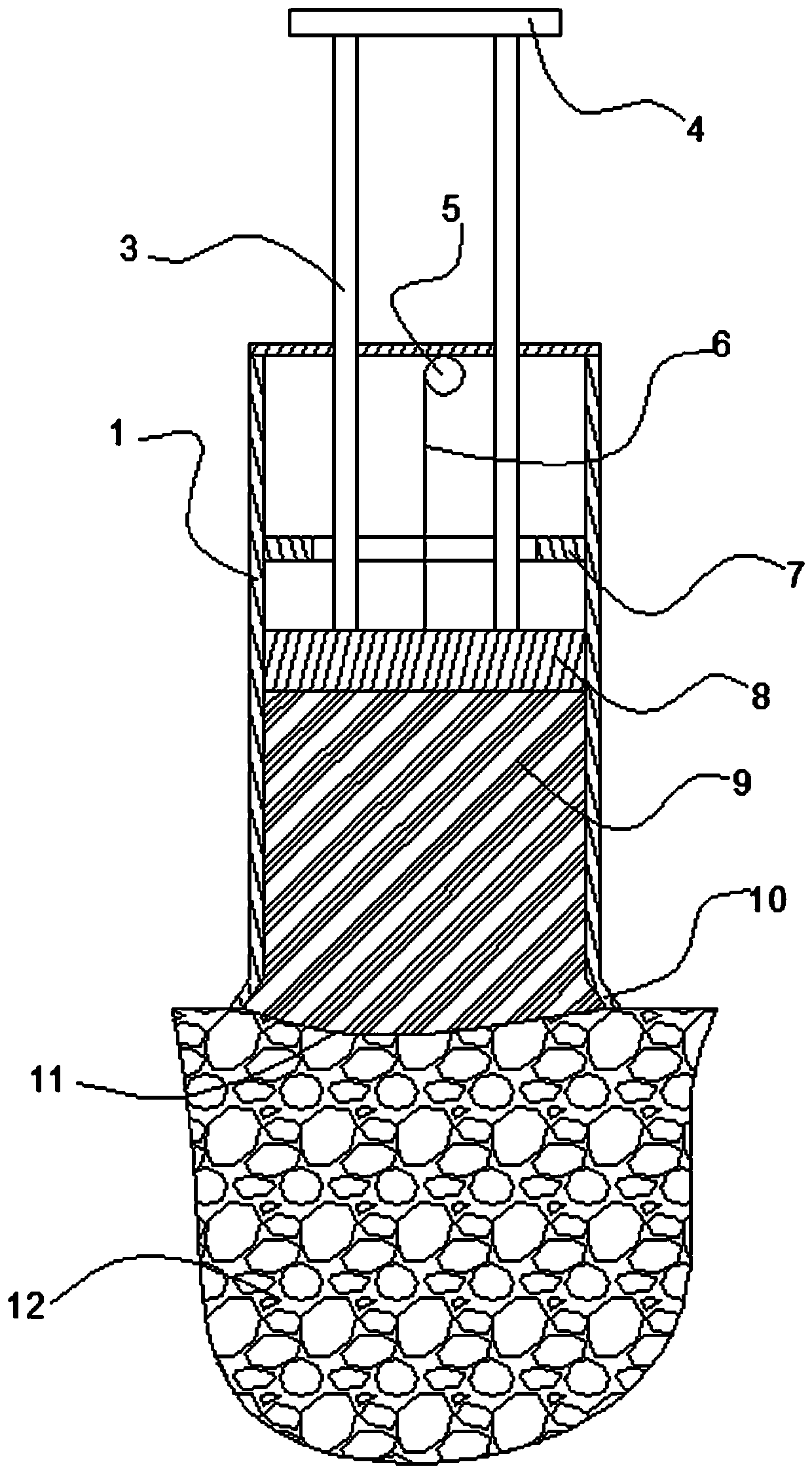

Pit-digging volume detection device and method for detecting subgrade compaction degree by pit-digging method

PendingCN110749262AReduce labor intensityUsing optical meansVolumetric dimension measurementsPistonPiston cylinder

The invention relates to a pit-digging volume detection device and method for detecting the subgrade compaction degree of a pit-digging method. The pit-digging volume detection device comprises a piston cylinder, and a piston is assembled in the piston cylinder in a guide mode. A piston push rod is connected to one side of the piston, a solid flexible body for filling the corresponding to-be-drilled road surface or detection hole by being ejected and pushed by the piston is arranged at the other end of the piston. The solid flexible body is of a cylindrical structure with the outer diameter same as the inner diameter of the piston cylinder. The pit-digging volume detection device further comprises a stroke detection structure for measuring the movement stroke of the piston. The pit-diggingvolume detection device and method solve the technical problem of high work intensity caused by sand recovery due to the fact that sand filling is used for performing pit-digging volume detection inthe prior art.

Owner:HENAN VOCATIONAL & TECHN COLLEGE OF COMM +1

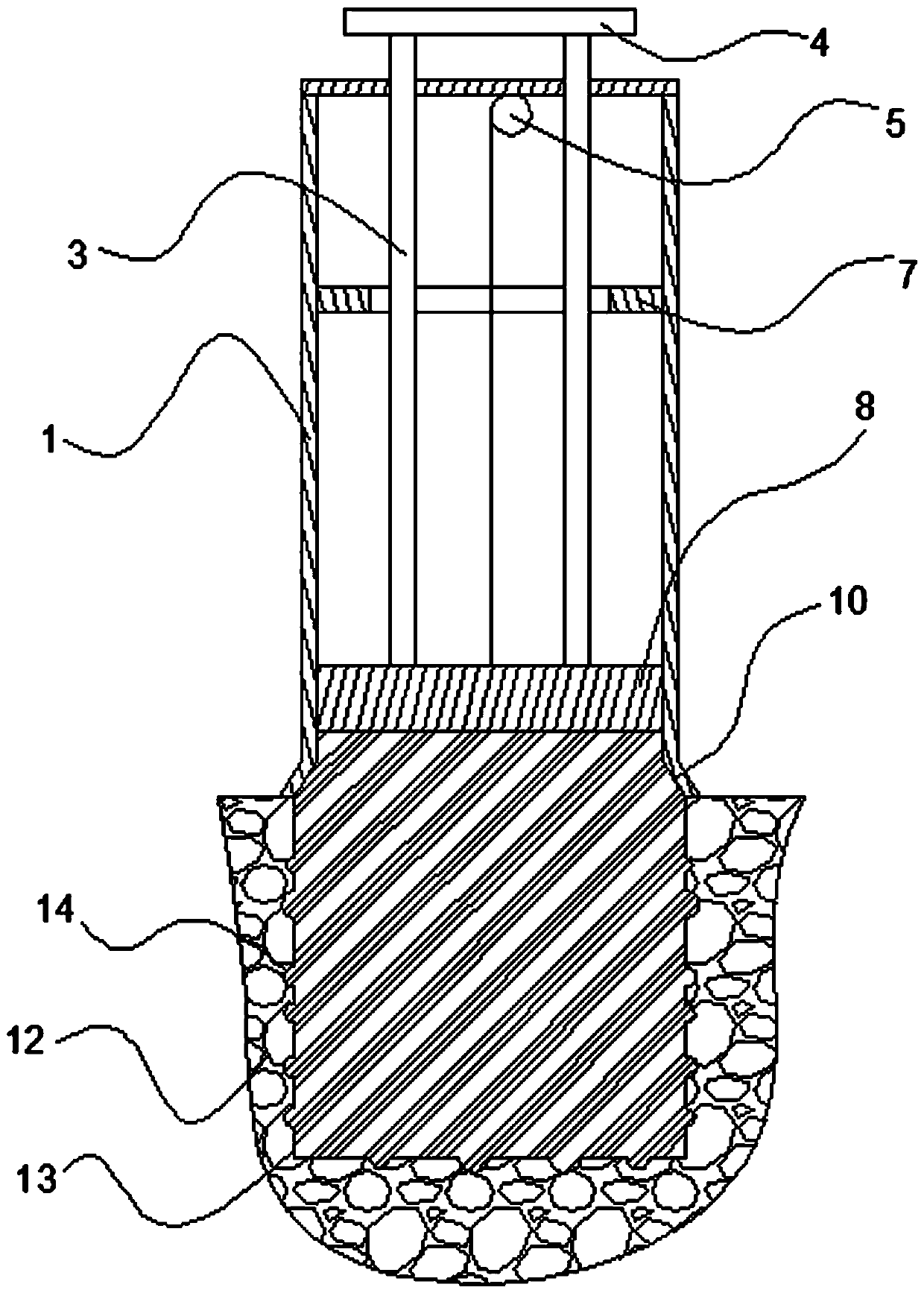

Calibration device for volume expansion measurement instrument of solid

ActiveCN107843176ARealize metrological traceabilityAdjustable lengthNuclear energy generationVolumetric dimension measurementsRatchetReciprocating motion

The invention relates to a calibration device for a volume expansion measurement instrument of solid, and the device is provided with a hollow pedestal which is fixed on a front wall of a testing cavity of the expansion measurement instrument. The joint of the pedestal with the wall of the testing cavity of the expansion measurement instrument is sealed in a form of a static sealing structure through a second annular sealing ring. The cavity of the pedestal is provided with a first annular sealing ring in a sleeved manner. A rear screw of a pair of spiral micrometer heads is inserted into thecavity of the pedestal in a form of a moving sealing structure through the first annular sealing ring, and then the rear end of the screw is enabled to enter the testing cavity of the expansion measurement instrument in a threaded manner. The front parts of the spiral micrometer heads are provided with ratchet wheels, and the rotation of the ratchet wheels can drive the rear screw of the spiral micrometer heads to make reciprocating motion in the axial direction of the cavity of the pedestal. According to the invention, the internal environment of the testing cavity of the expansion measurement instrument is not changed before and after calibration, and the volume calibration can be carried out according to the needs. The device achieves the repeated calibration, and controls the random error. The device also has the capabilities of increasing the volume and reducing the calibration.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

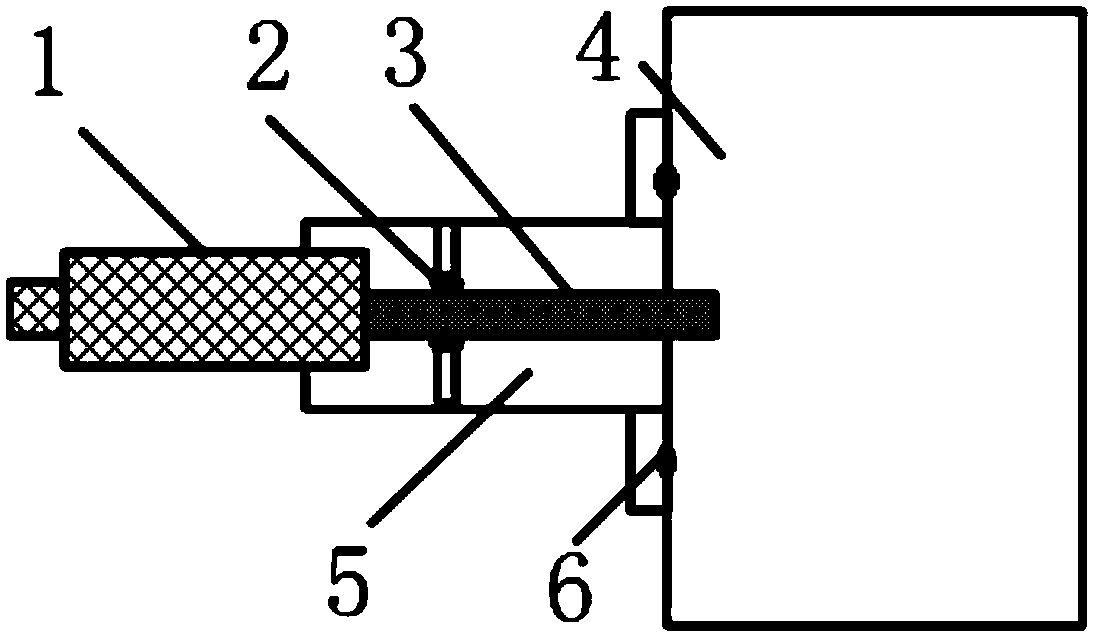

Device and method for measuring volume expansion characteristics of material under tensile load

PendingCN111198131AGuaranteed accuracyGuaranteed identityMaterial strength using tensile/compressive forcesContainer/cavity capacity measurementPhysicsMicrometer

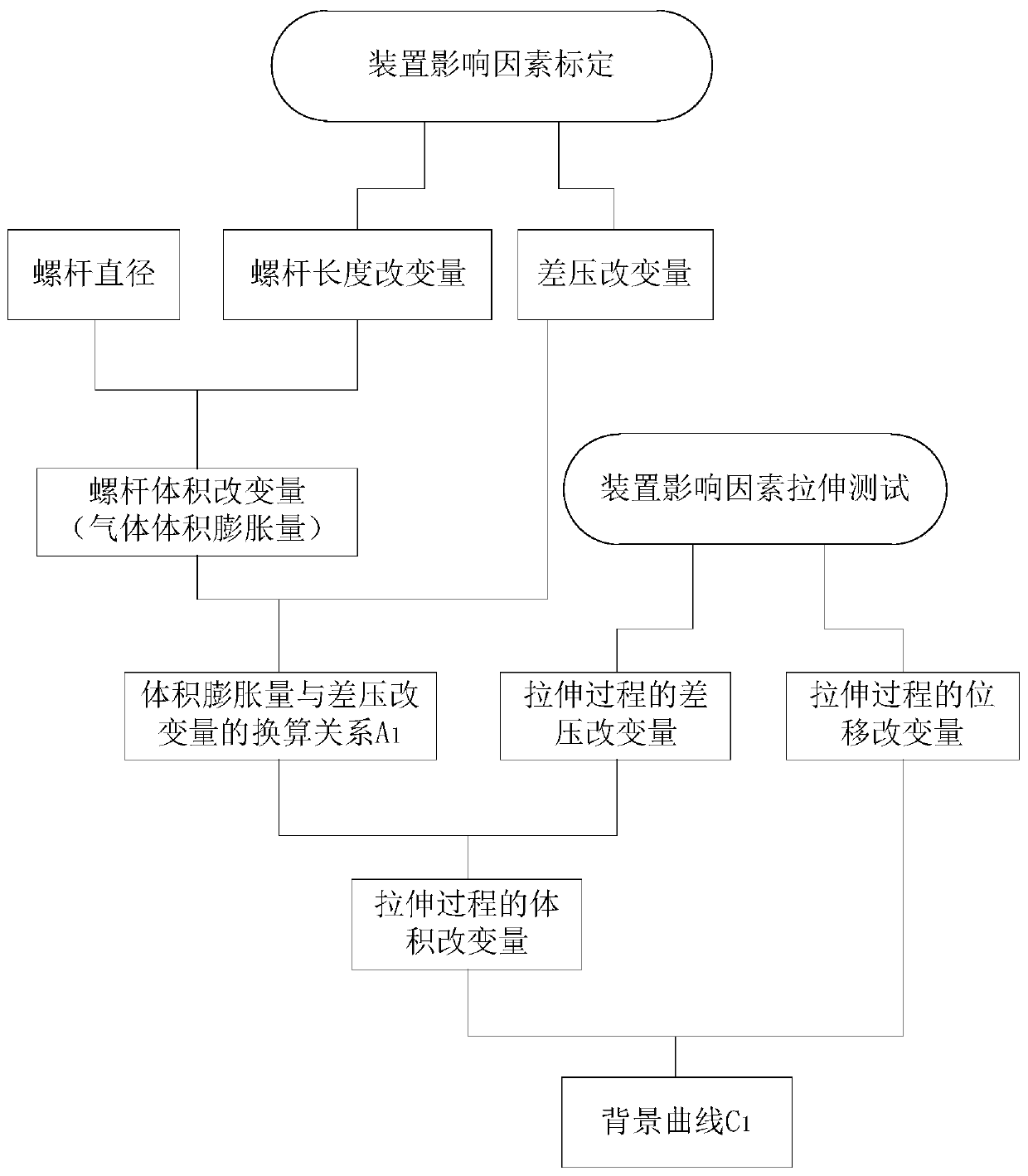

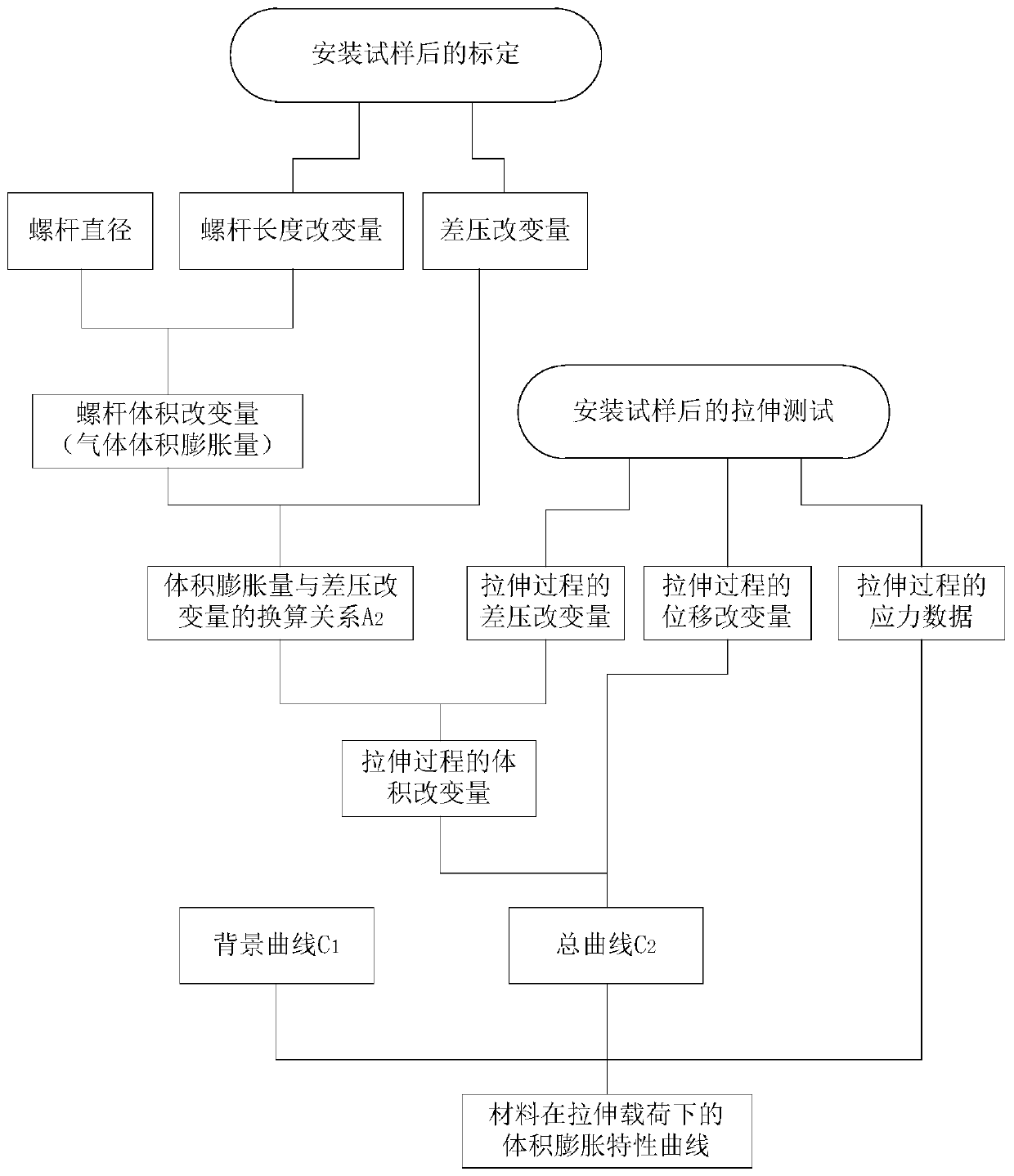

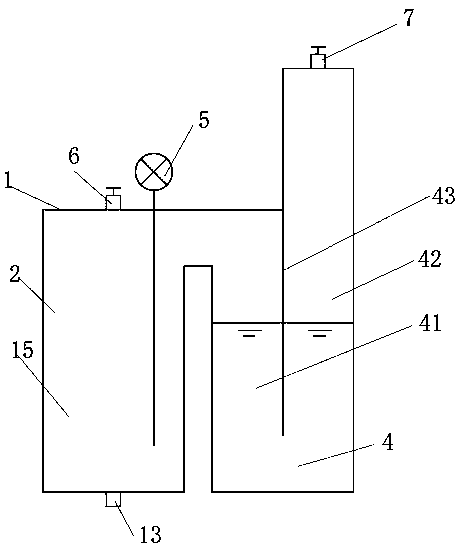

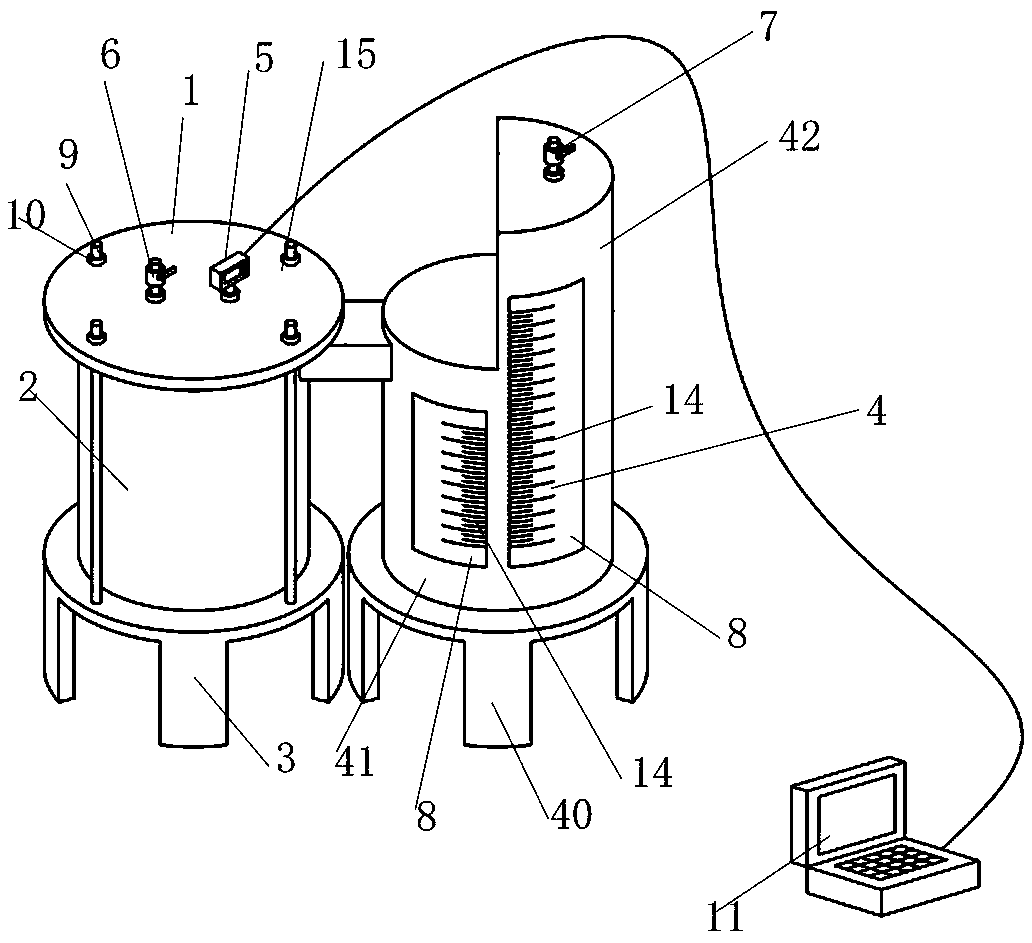

The invention discloses a device and a method for measuring the volume expansion characteristic of a material under a tensile load. The device comprises a stretching rod, a compensation rod, a reference cavity, a differential pressure gauge and a micrometer caliper. Screws of the stretching rod, the compensation rod and the micrometer caliper respectively extend into a test cavity through specificmounting seats, the stretching rod and the compensation rod are the same in material size specification and are fixedly connected in the test cavity, and the moving directions are opposite in the stretching process. The measurement process is divided into three stages of background curve measurement, total curve measurement and data comprehensive processing. In the background curve determinationstage, a background curve representing the relationship between volume change data and displacement data caused by device factors in the stretching process is obtained through calibration and stretching test under the condition of no sample; in the total curve determination stage, a total curve representing the relationship between total volume change data and displacement data in the stretching process is obtained through calibration and stretching test after sample installation; in the data comprehensive processing stage, the inflection point of the force curve is used for determining starting point displacement in the stretching process, and a volume expansion characteristic curve is obtained in combination with the background curve and the total curve.

Owner:西安航天三沃机电设备有限责任公司

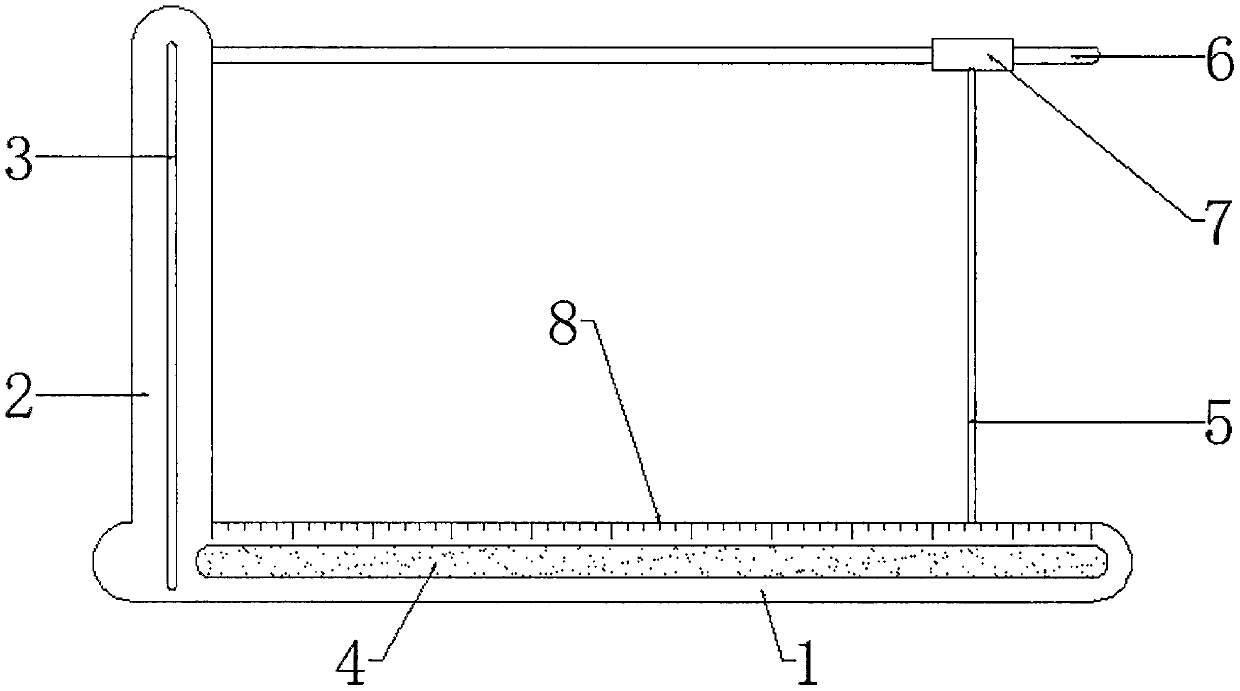

Test device and test method for measuring free expansion volume of high polymer

PendingCN110501375AIntuitive and clear measurementMaterial thermal coefficient of expansionVolumetric dimension measurementsExhaust valveCommunicating vessels

The invention provides a test device and a test method for measuring the free expansion volume of a high polymer. The test device for measuring the free expansion volume of the high polymer comprisesa test chamber and a measurement chamber, and the test chamber and the measurement chamber are communicated. The test chamber is provided with a temperature measurement device. The test chamber is further provided with a grouting head and an exhaust valve. A partition plate which divides the measurement chamber into a measurement chamber A and a measurement chamber B is arranged in the measurementchamber. Only the lower ends of the measurement chamber A and the measurement chamber B are communicated, and the measurement chamber A and the measurement chamber B form a communicating vessel. Themeasurement chamber A is communicated with the test chamber A. The measurement chamber B is communicated with the test chamber through the measurement chamber A. Observation windows are arranged on the measurement chamber A and the measurement chamber B respectively. Scales are arranged on the observation windows. The upper end of measurement chamber B is open or provided with a valve communicatedwith the outside. A more complete device is provided for the study of the free expansion characteristic of the high polymer. The acquired test result can provide a basis for the study of the groutingrepair of an infrastructure safety protection high polymer.

Owner:ZHENGZHOU UNIV +1

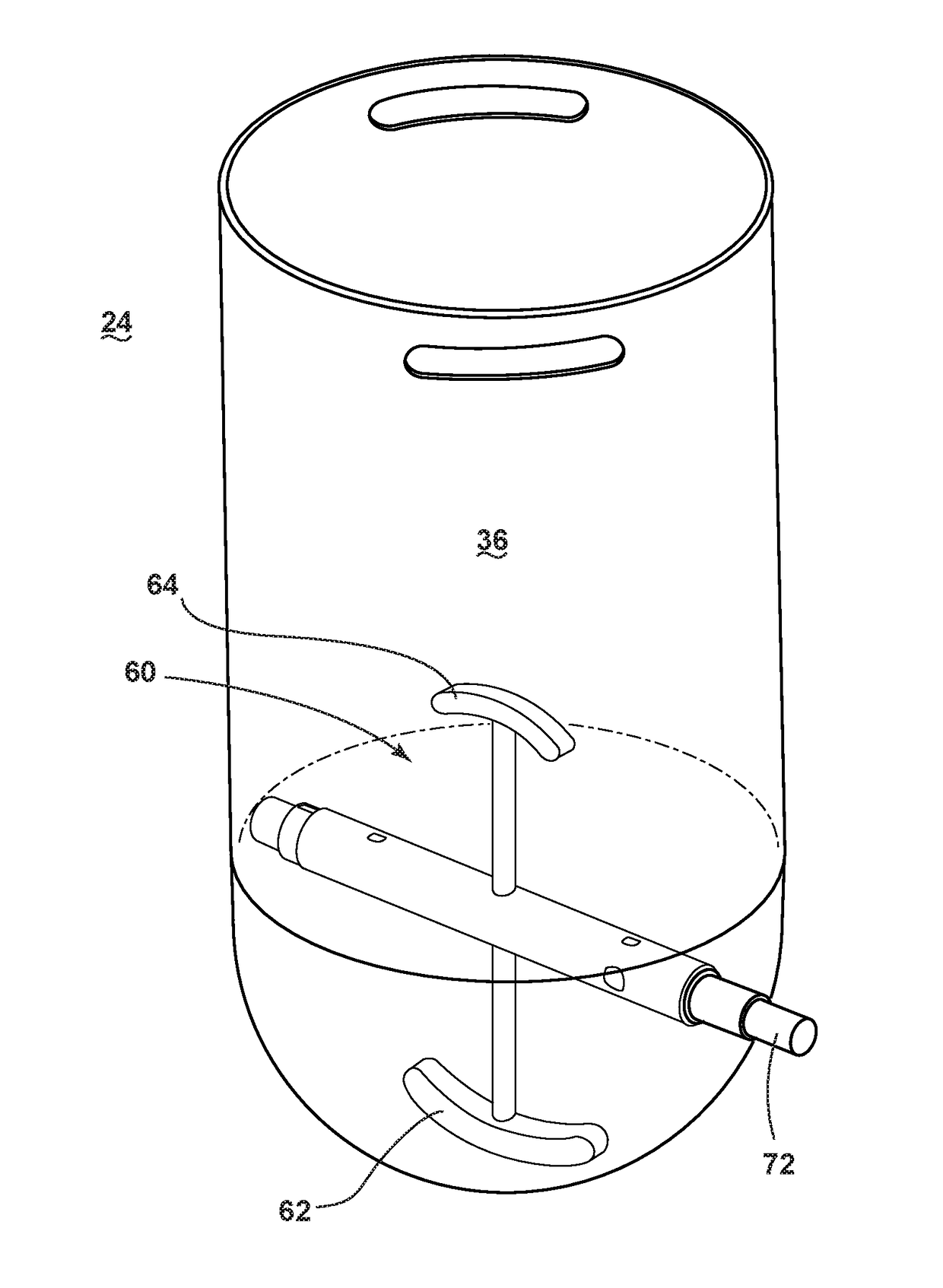

Composting device

A method of determining the volume of organic material in a composting device includes rotating a mixing paddle in a composting bin that stores the organic material; monitoring the torque from a motor that rotates the mixing paddle as the mixing paddle rotates; and determining the height of the organic material in the composting bin based on the motor torque and the angular displacement of the mixing paddle. The resulting height can be used to determine the volume of the organic material.

Owner:WHIRLPOOL CORP

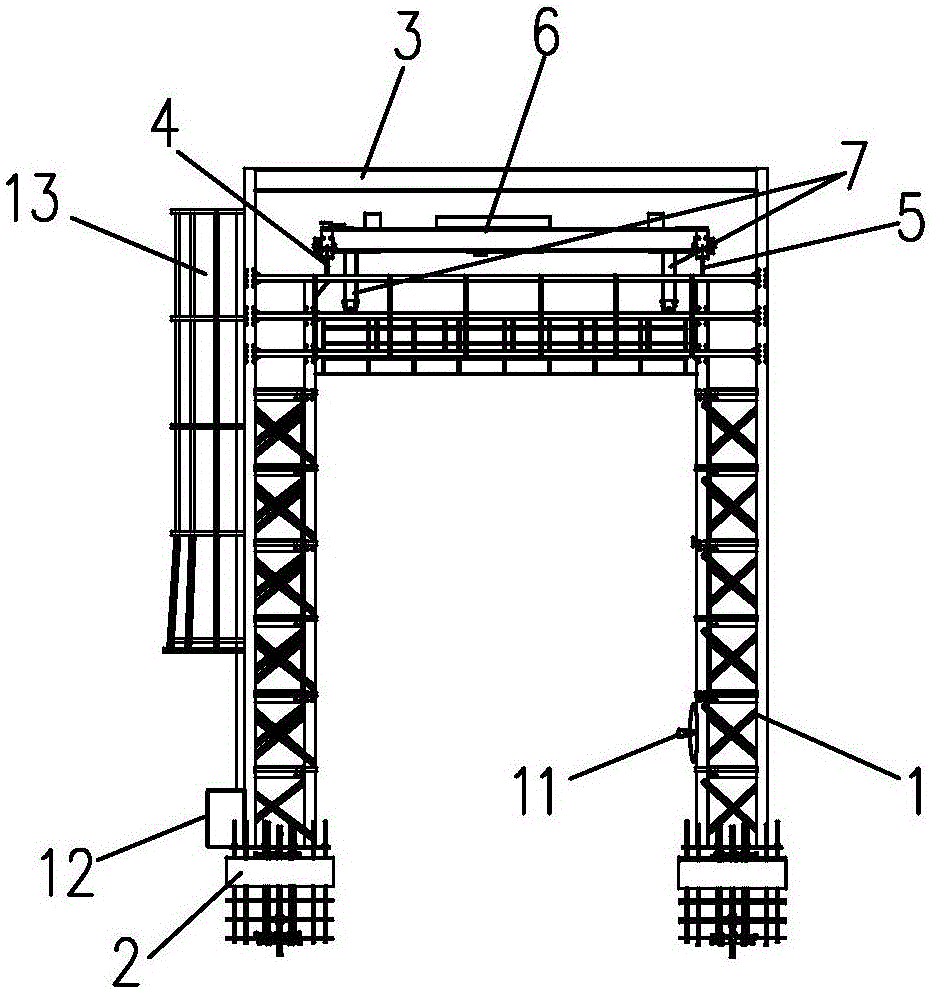

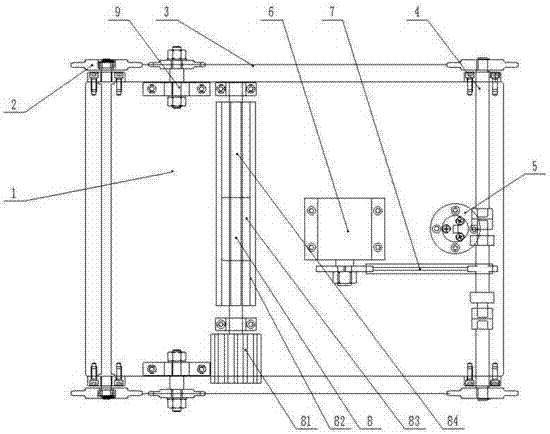

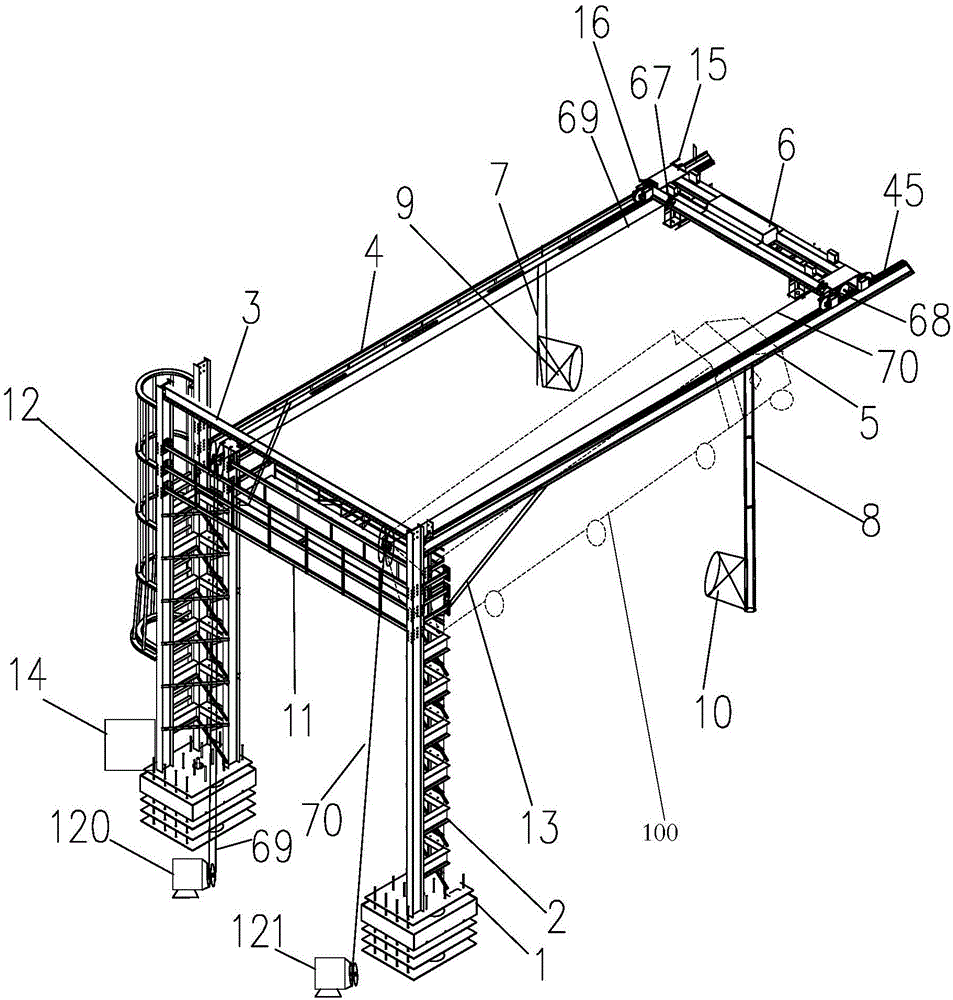

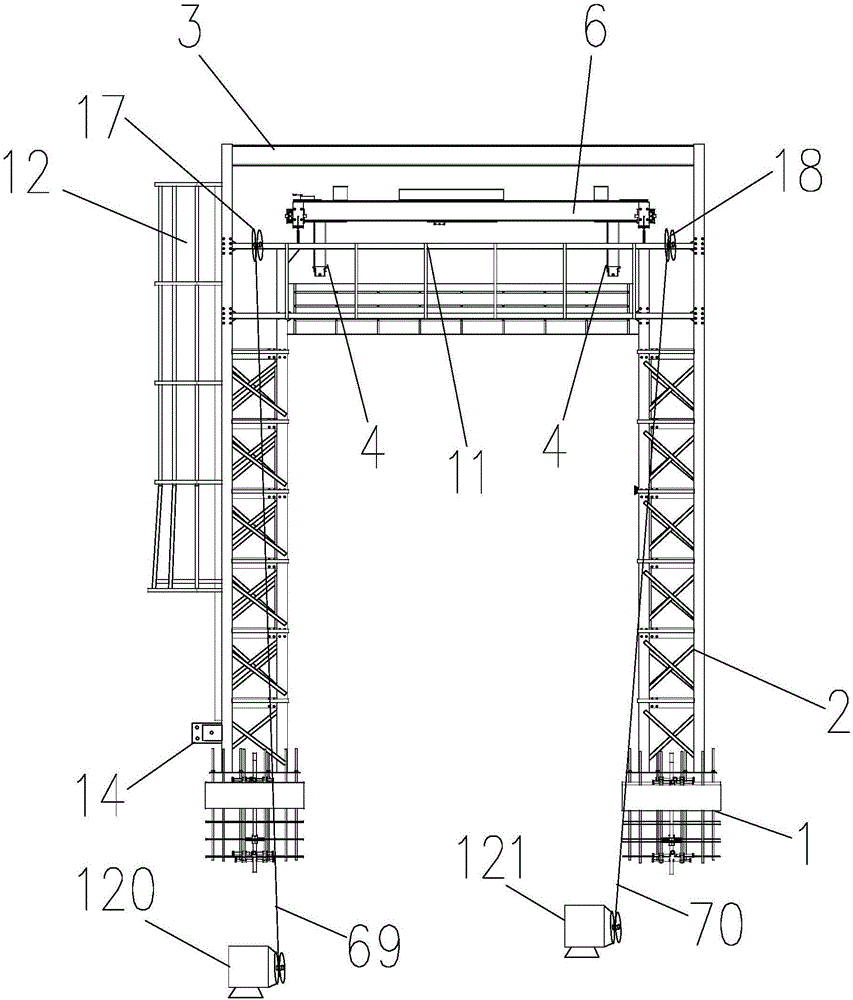

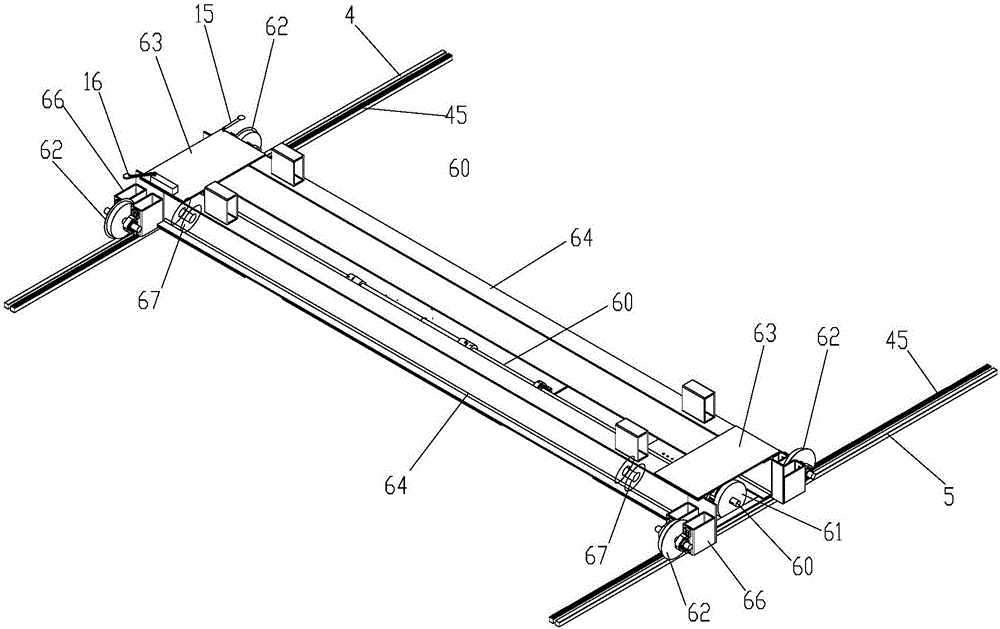

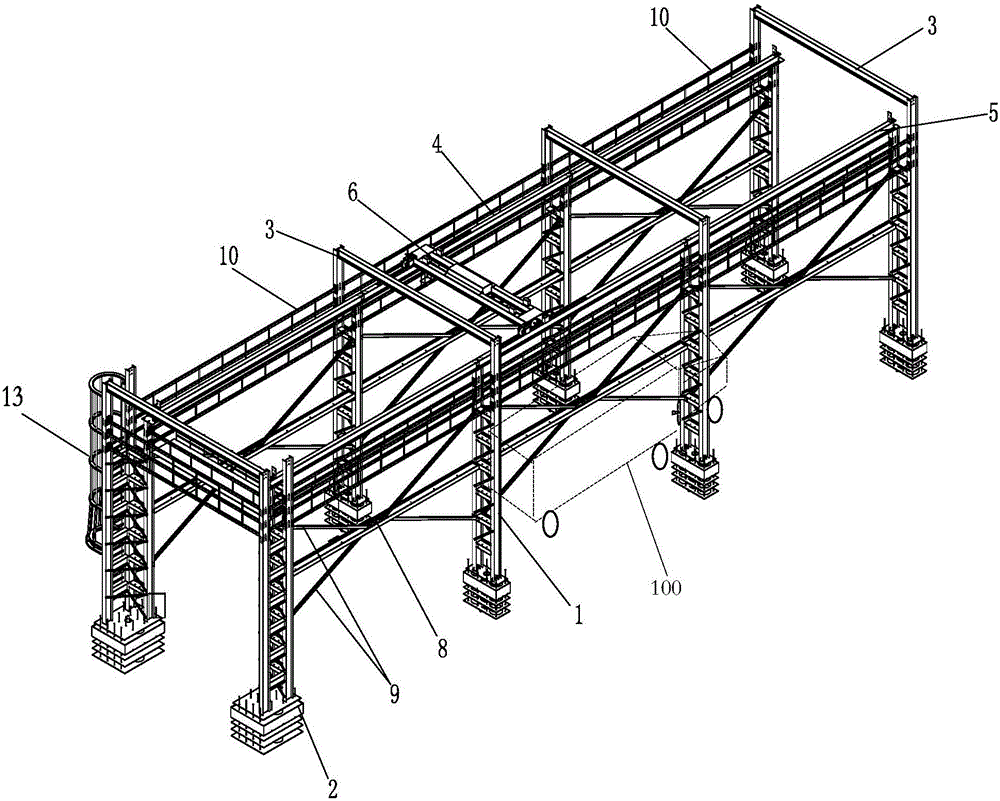

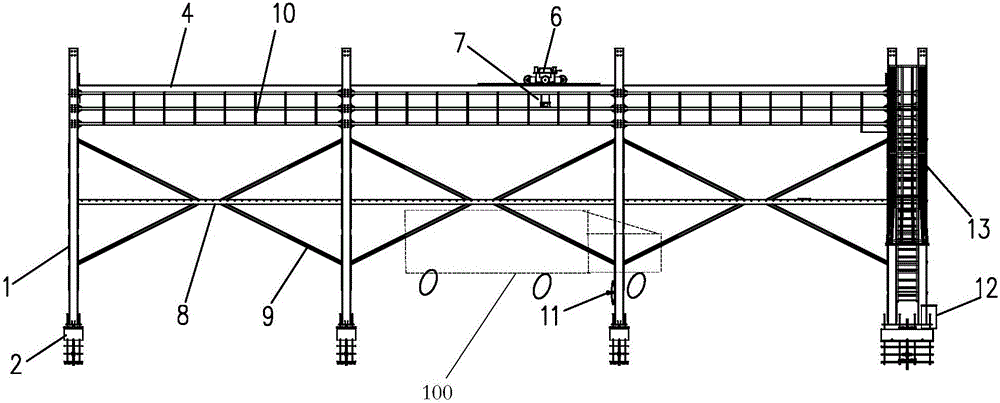

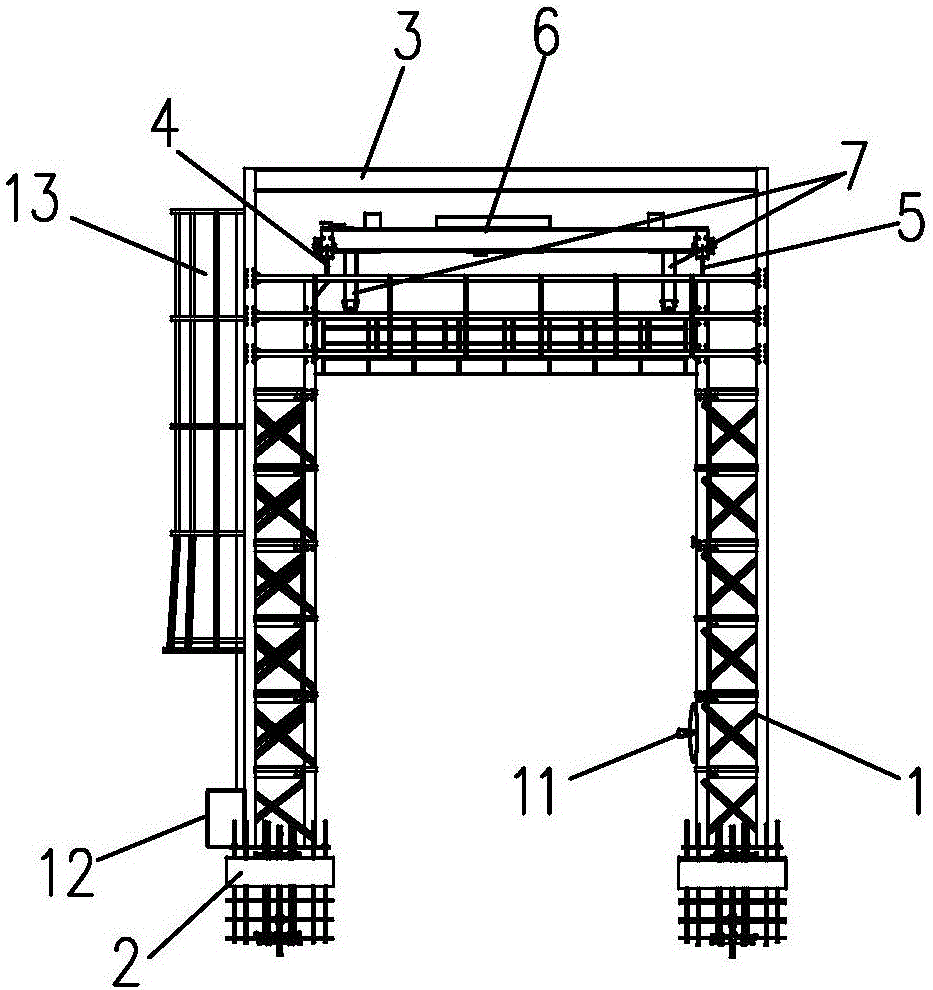

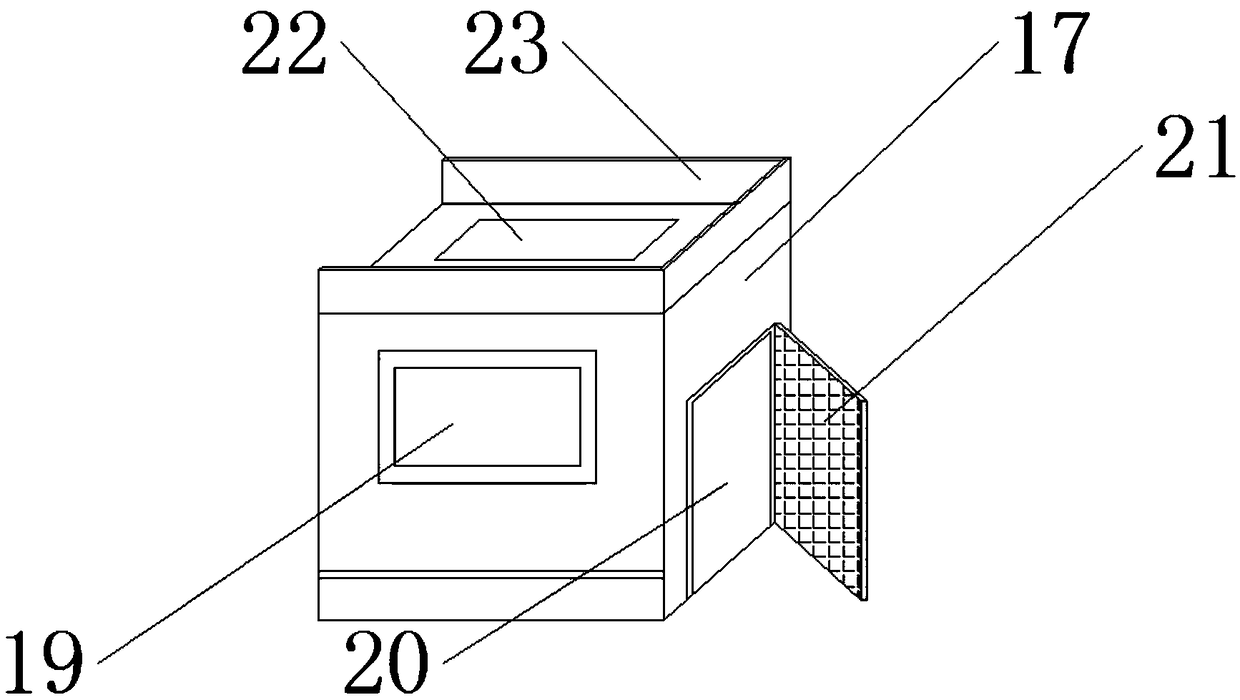

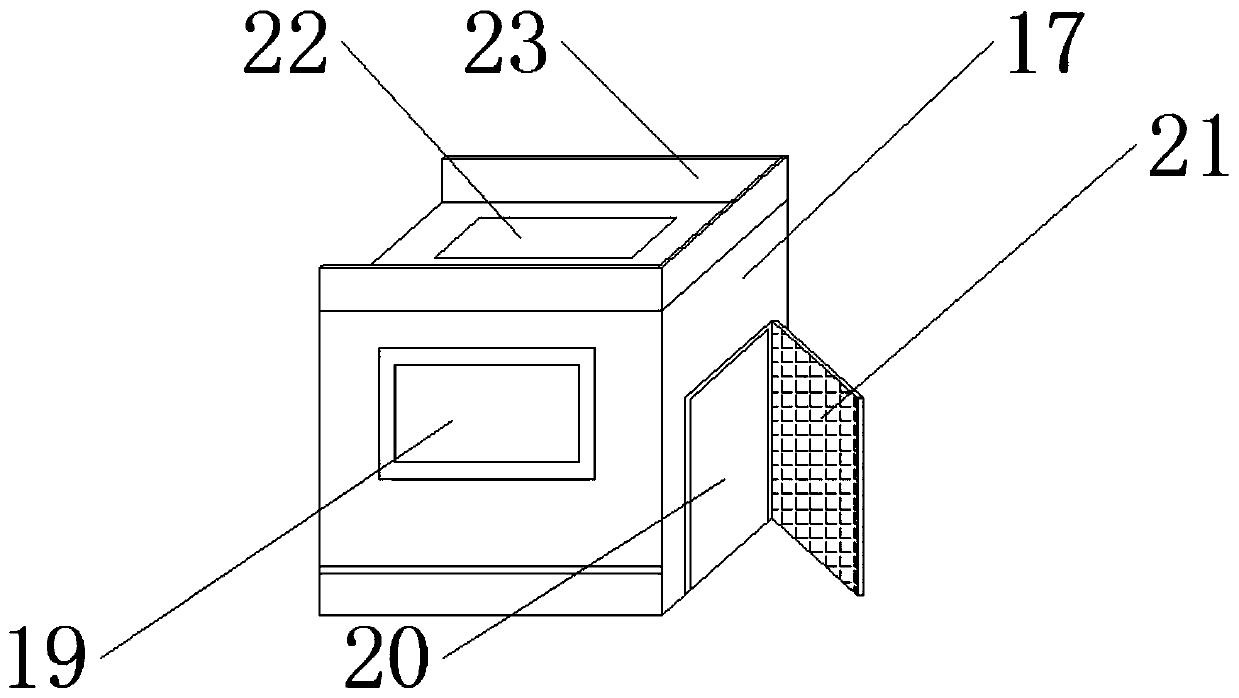

Vehicle carriage volume measurement mechanism based on portal frame

ActiveCN106197278ASimple designOptimal Design StructureUsing optical meansVolumetric dimension measurementsControl systemData acquisition

The invention discloses a vehicle carriage volume measurement mechanism based on a portal frame, and the mechanism comprises an electrical box control system, the portal frame, a first groove-type linear guide rail and a second groove-type guide rail, wherein the first groove-type linear guide rail and the second groove-type guide rail are arranged in parallel. One end of the first groove-type linear guide rail and one end of the second groove-type guide rail are respectively disposed on the portal frame. The other end of the first groove-type linear guide rail and the other end of the second groove-type guide rail are suspended. The portal frame comprises a substrate, a cross beam, and two vertical frames which are set oppositely. The cross beam is fixed at the tops of the two vertical frames, and the bottoms of the two vertical frames are fixed on the substrate. A walking mechanism is connected between the first groove-type linear guide rail and the second groove-type guide rail in a bridging manner. A first data collection device is disposed below the walking mechanism, and is in communication connection with the installed electrical box control system through a data line. The mechanism can quickly measure the size of goods in a vehicle carriage, is small in measurement error, and is convenient to control.

Owner:GUANGXI WODEKEJI TECH

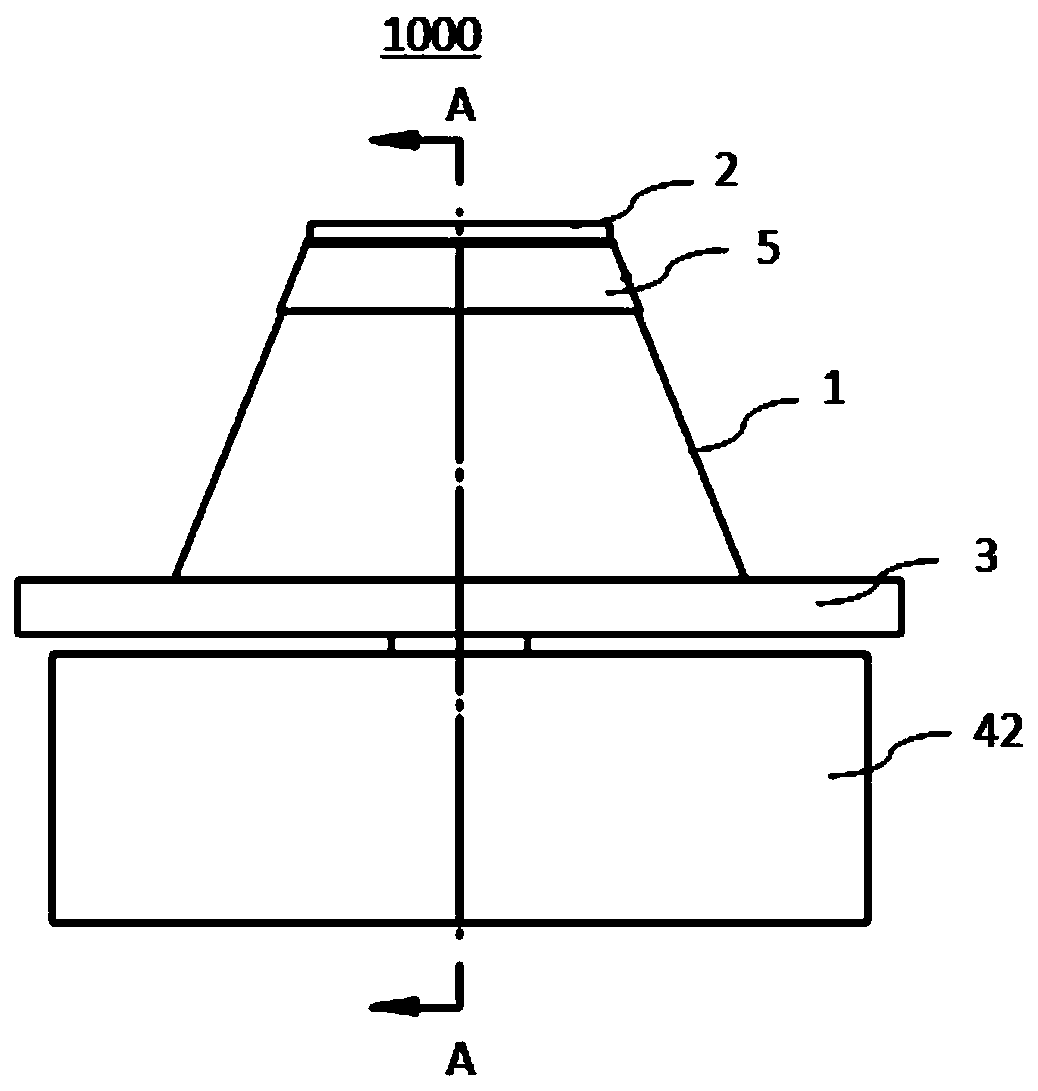

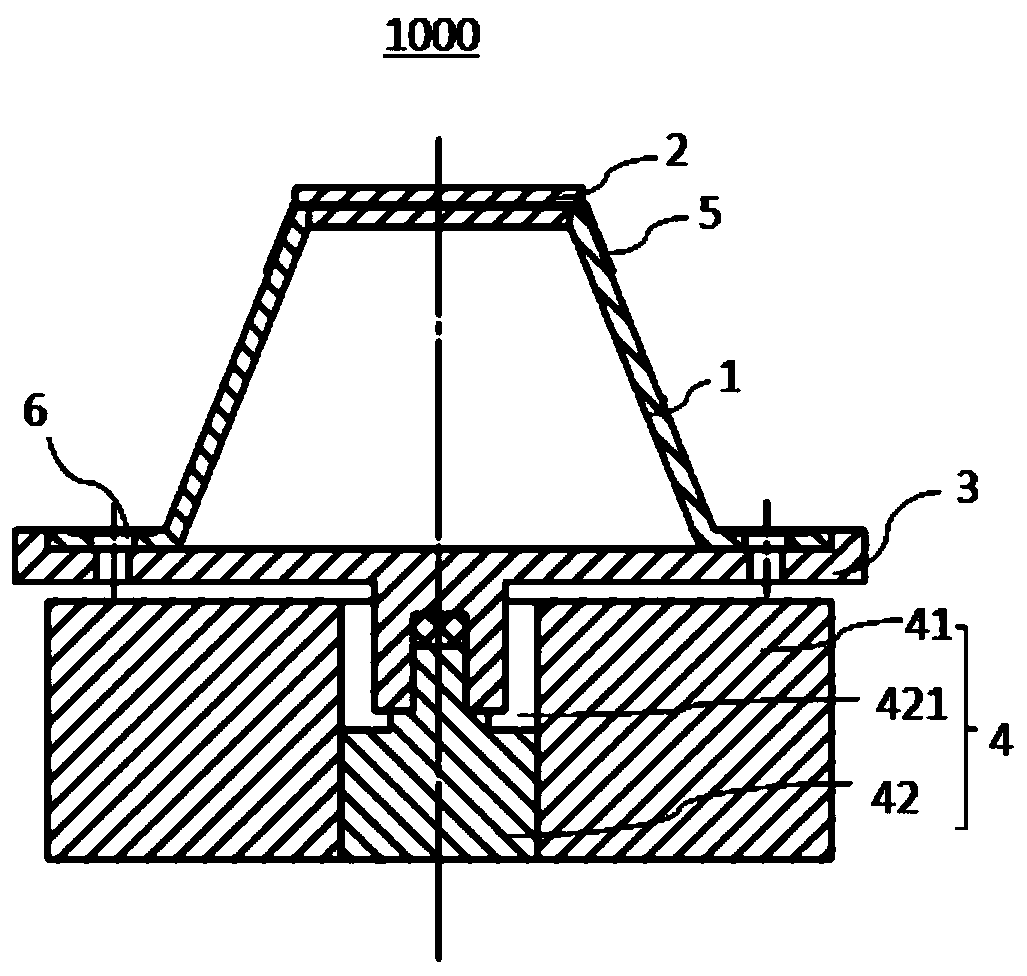

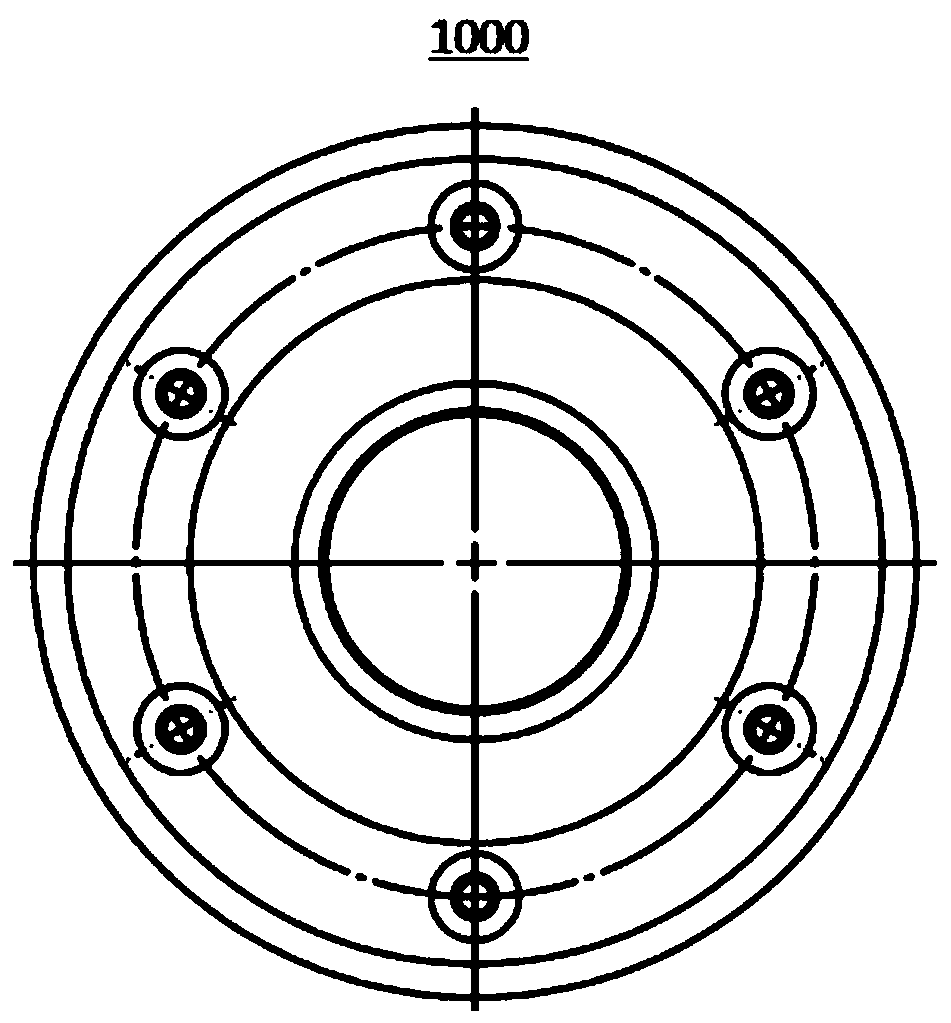

Test device and test method for gelation curing volume shrinkage

PendingCN109975531ATest accurateMeet measurement needsMaterial testing goodsVolumetric dimension measurementsMeasurement deviceEngineering

The invention discloses a measurement device and a test method for gelation curing volume shrinkage. The measurement device comprises a truncated cone-shaped container, a top cover, a platform and a uniform curing assembly, wherein the truncated cone-shaped container is provided with an upper opening and a lower opening, and the side wall of the truncated cone-shaped container is marked with a first volume shrinkage scale and a calibration scale of the initial addition amount of resin; the top cover is covered on the upper opening of the truncated cone-shaped container; the platform is locatedbelow the truncated cone-shaped container, the lower opening of the truncated cone-shaped container is located on the upper surface of the platform, and the truncated cone-shaped container is detachably fixed on the platform; and the uniform curing assembly is arranged below the platform to ensure that the resin added to the truncated cone-shaped container is uniformly cured. The measurement device is accurate in resin curing volume shrinkage test, can directly read the resin curing volume shrinkage, and is simple and convenient to test.

Owner:TSINGHUA UNIV

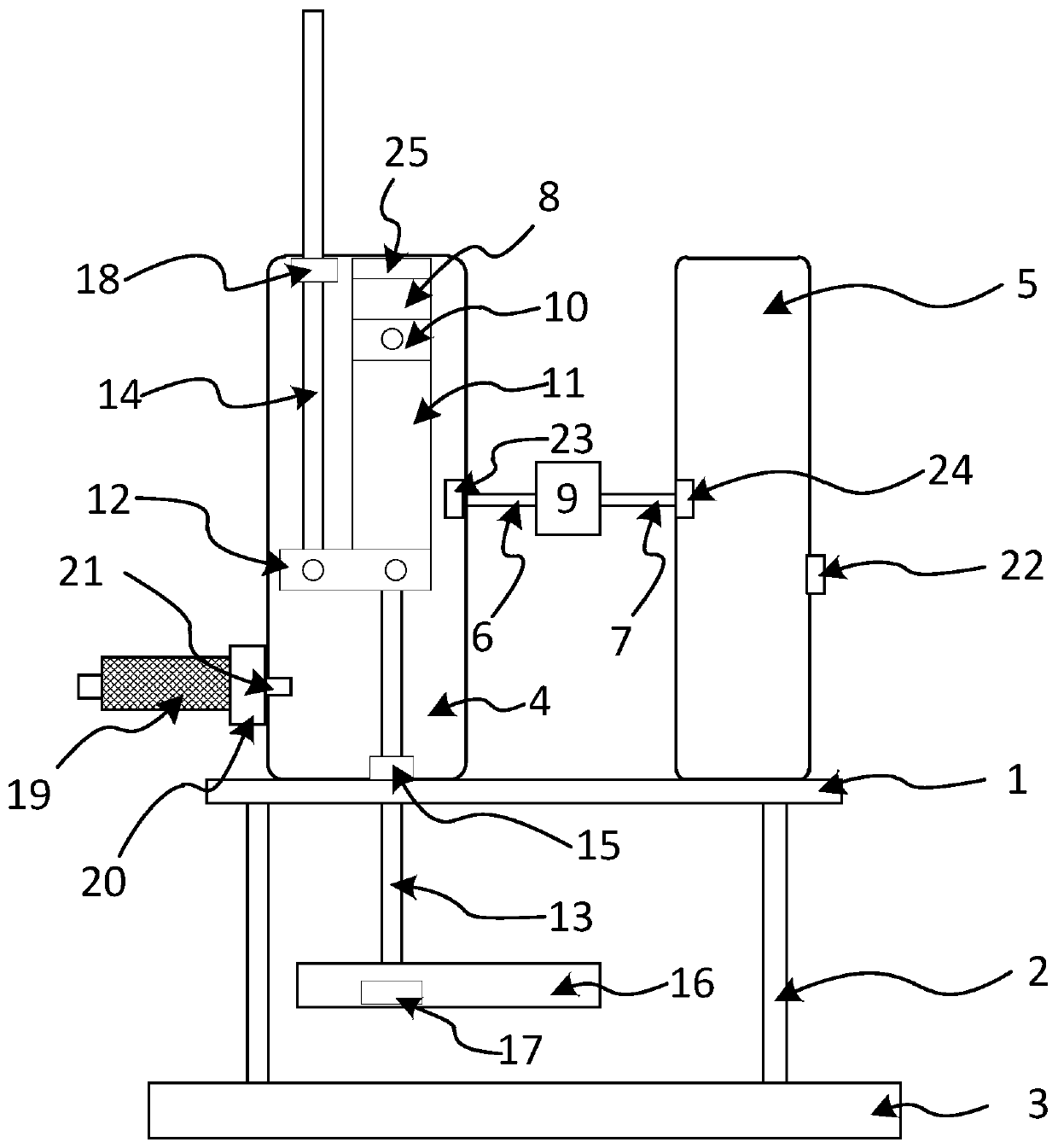

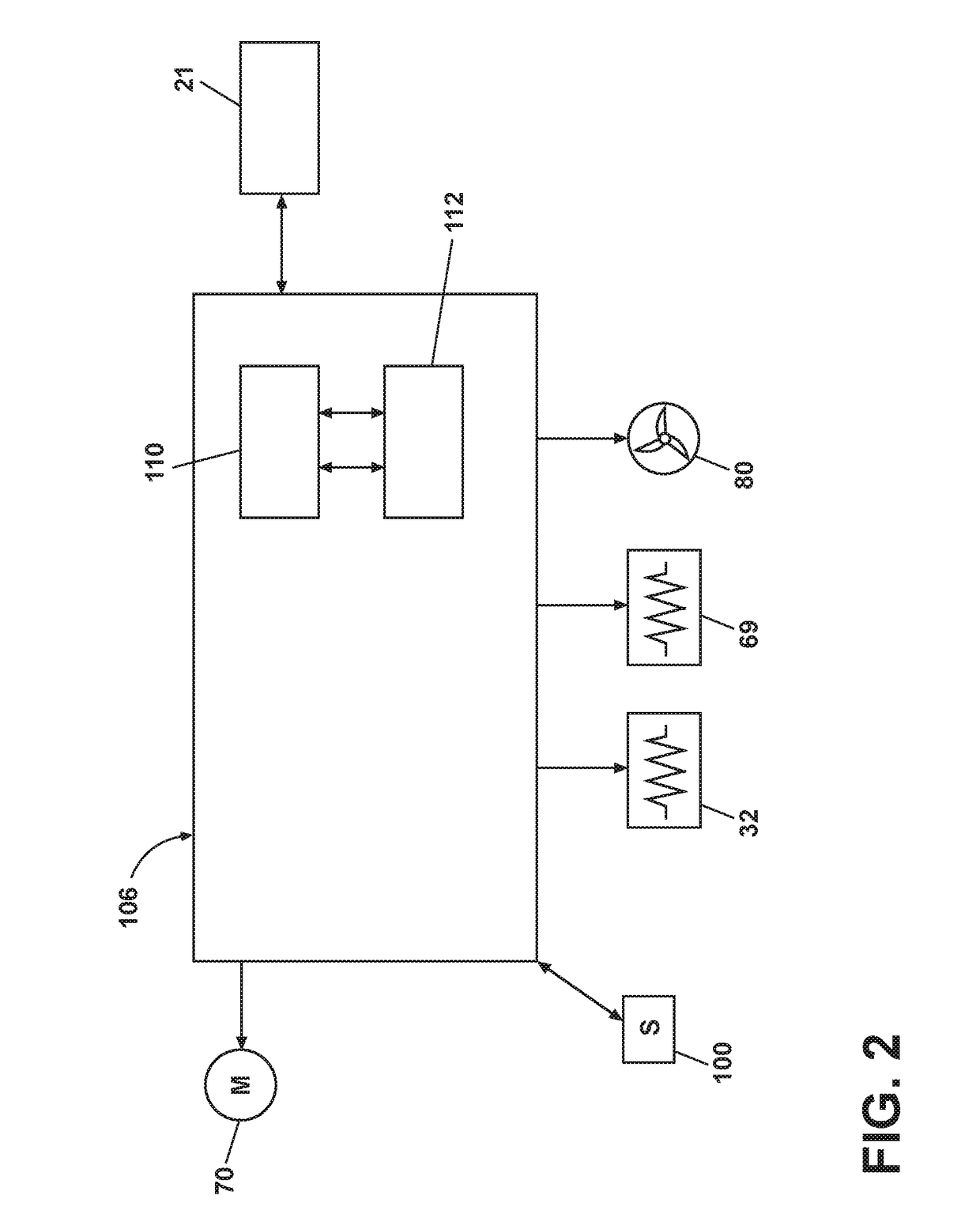

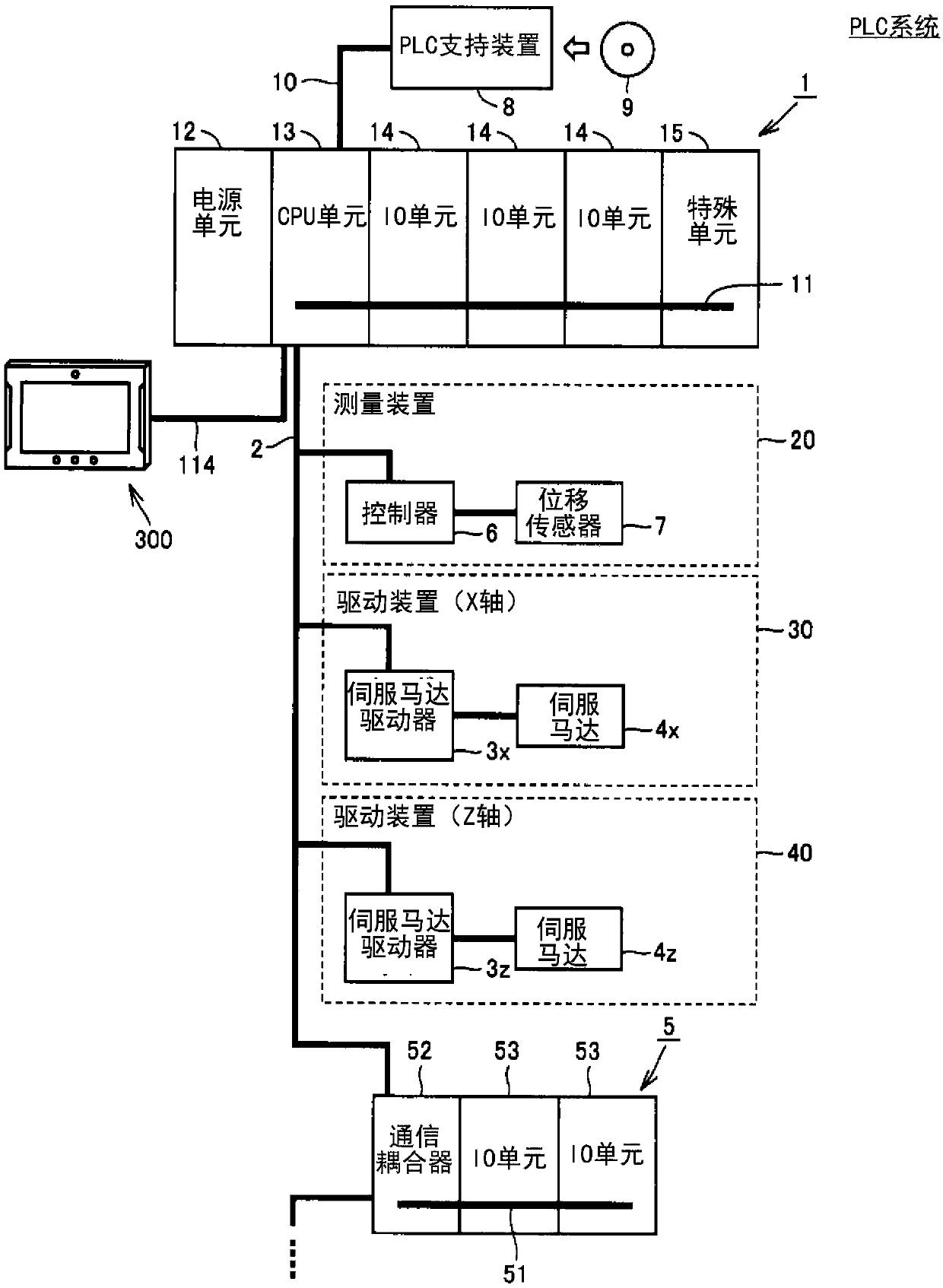

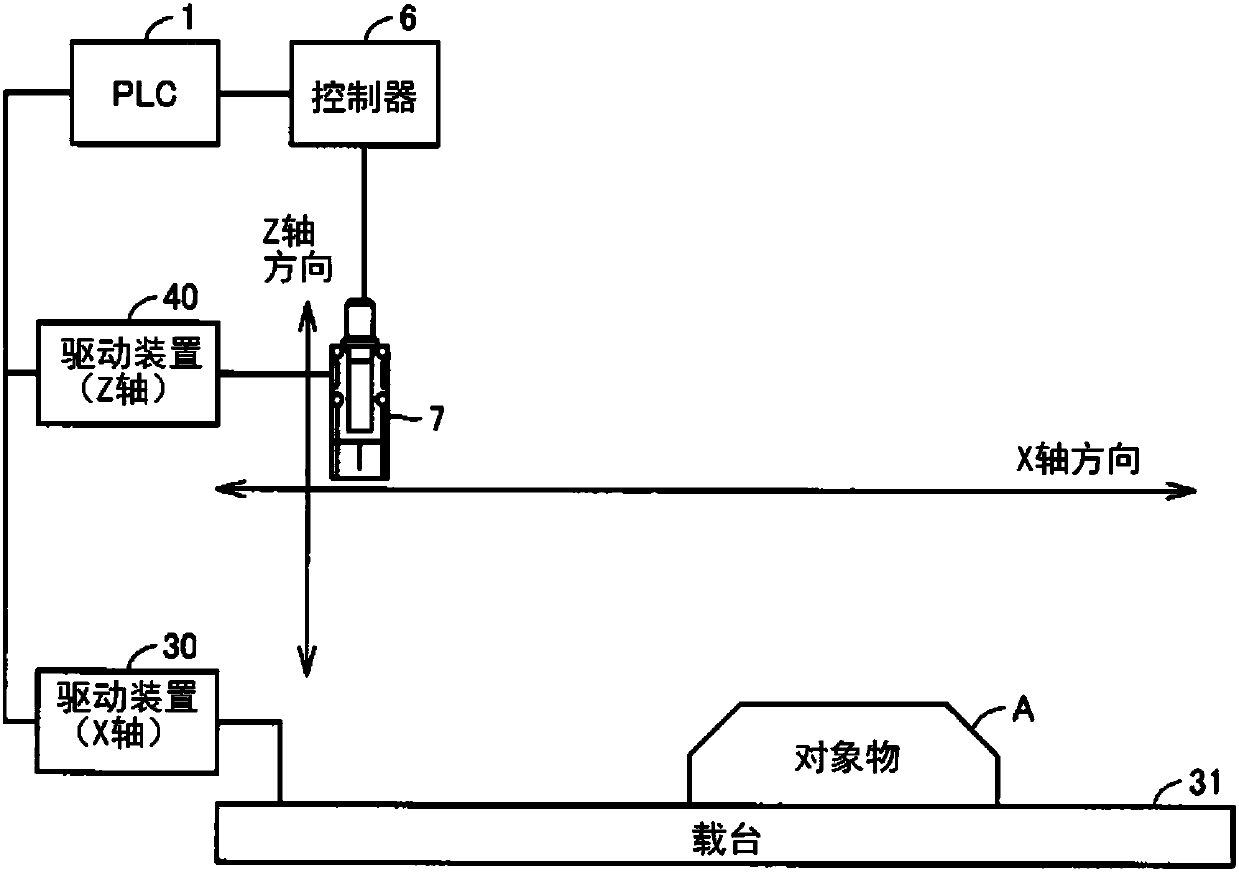

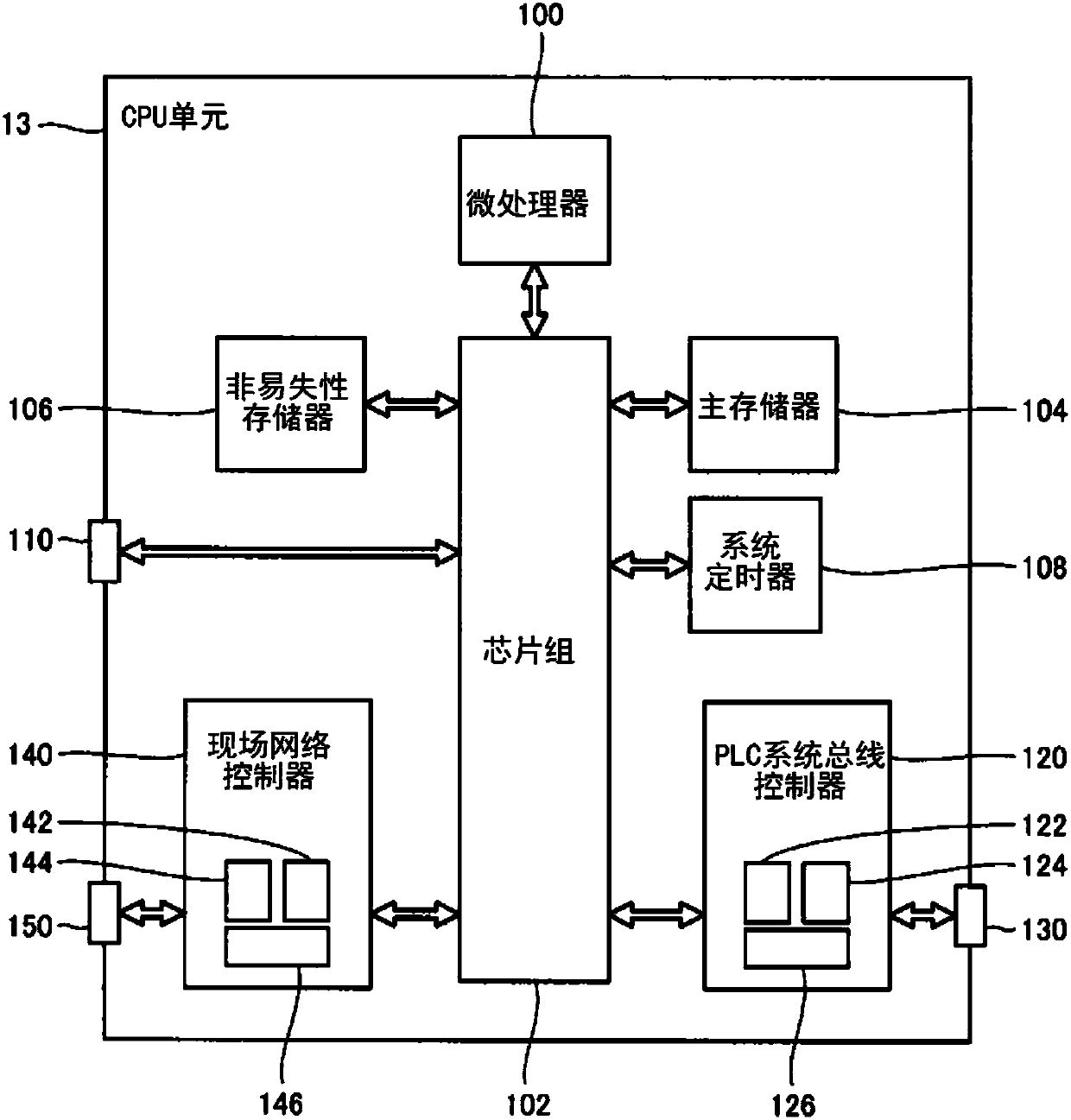

Control system, and control method and computer readable storage medium

ActiveCN108021089AReduce vibrationShorten takt timeAngles/taper measurementsMeasurement/indication equipmentsControl systemComputer science

A control system, a method, and a computer readable storage medium reduce oscillations in trace control and shorten the tact time in measurement. A PLC system (SYS) includes a displacement sensor (7),drives (30, 40), and a PLC (1). In the PLC system (SYS), the trace control unit (162) calculates a target position at which a distance between the displacement sensor (7) and the object (A) is constant based on measurement information (1D information) from which measurement noise (noise information) has been removed by the filter (162c) and positional information from the drives (30, 40).

Owner:ORMON CORP

Wall-climbing robot for measuring capacity of vertical metal tanks

PendingUS20210048327A1Labor intensiveHigh riskGripping headsHollow article cleaningMicrocontrollerControl engineering

A wall-climbing robot for measuring capacity of vertical metal tanks includes a robot body including a chassis, a casing, and wheels. The robot body further includes: an attraction unit including a plurality of magnets; a measurement unit including a bendable ruler provided on the chassis and protruding from a top of the casing; the rust removal unit including a rust removing bucket provided at a front side of the robot body, and a driver for the lifting and lowering of the rust removing bucket; and a control unit including a microcontroller, a posture detector, an obstacle detector, an attraction detector, and a distance sensor. The wall-climbing robot of the present invention leaves no indentation on a surface of the metal tank, and is not affected by the rusts formed on the surface.

Owner:ZHOUSHAN INST OF CALIBRATION & TESTING FOR QUALITY & TECHNICAL SUPERVISION

Food fermentation box with fermentation volume monitoring function

InactiveCN112042704AImprove filtration efficiencyReduce cumbersome stepsContainer/cavity capacity measurementVolumetric dimension measurementsBiotechnologyTemperature control

The invention discloses a food fermentation box with a fermentation volume monitoring function. The food fermentation box comprises a box body; a temperature controller is installed in the box body; awater tank is arranged at the bottom of the box body; an electric heating tube is arranged at the bottom of the water tank; two trays are also movably arranged in the box body; furthermore, a fermentation vessel is arranged at the upper end of each tray; a fixed base is welded on the inner wall of the box body; a contrast test tube is inserted into the upper surface of the fixed base; furthermore, the tube wall of the contrast test tube is attached to the inner wall of the box body; and a magnetic ring is further connected into the contrast test tube in a sliding manner. The food fermentationbox in the invention has the advantages that: the expansion progress of the dough volume can be fed back in real time; a tedious step that a research and development person repeatedly opens the box body to check the fermentation progress is omitted; data errors caused by the fact that the temperature and humidity in the box body are changed due to opening of the box body can be effectively avoided; meanwhile, the dough fermentation efficiency is relatively higher; therefore, the research and development efficiency is improved; and use is more convenient.

Owner:德清县海杰包装有限公司

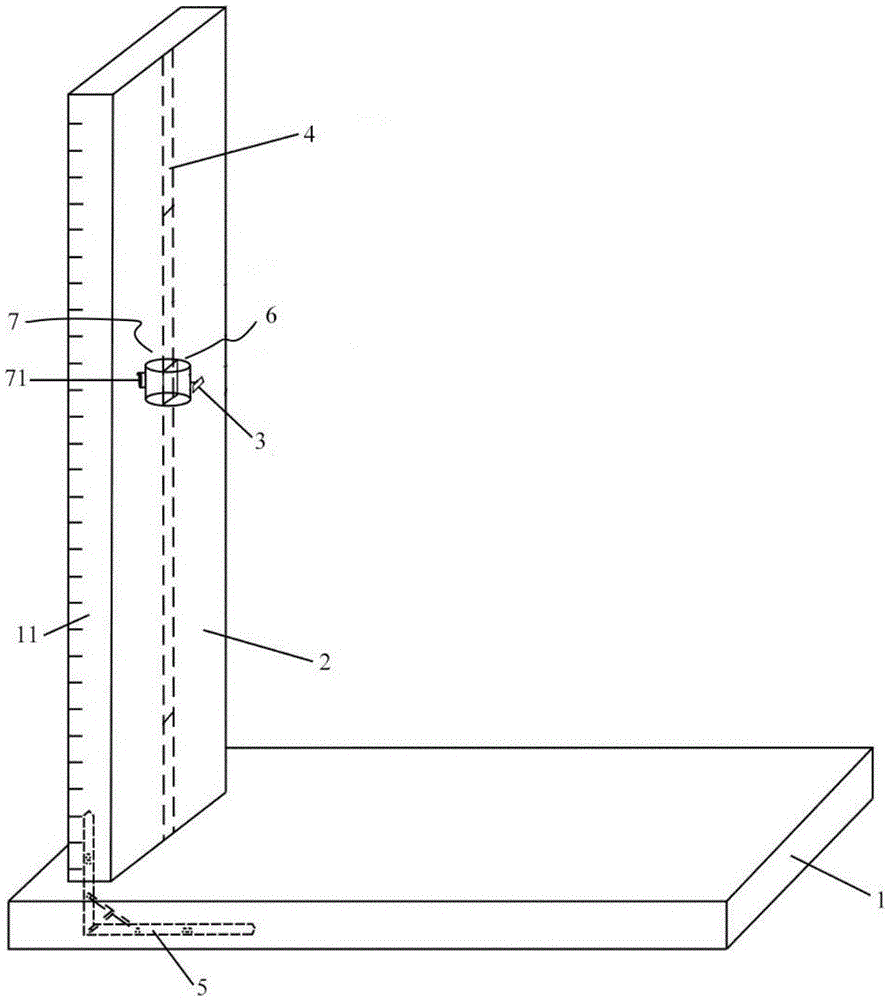

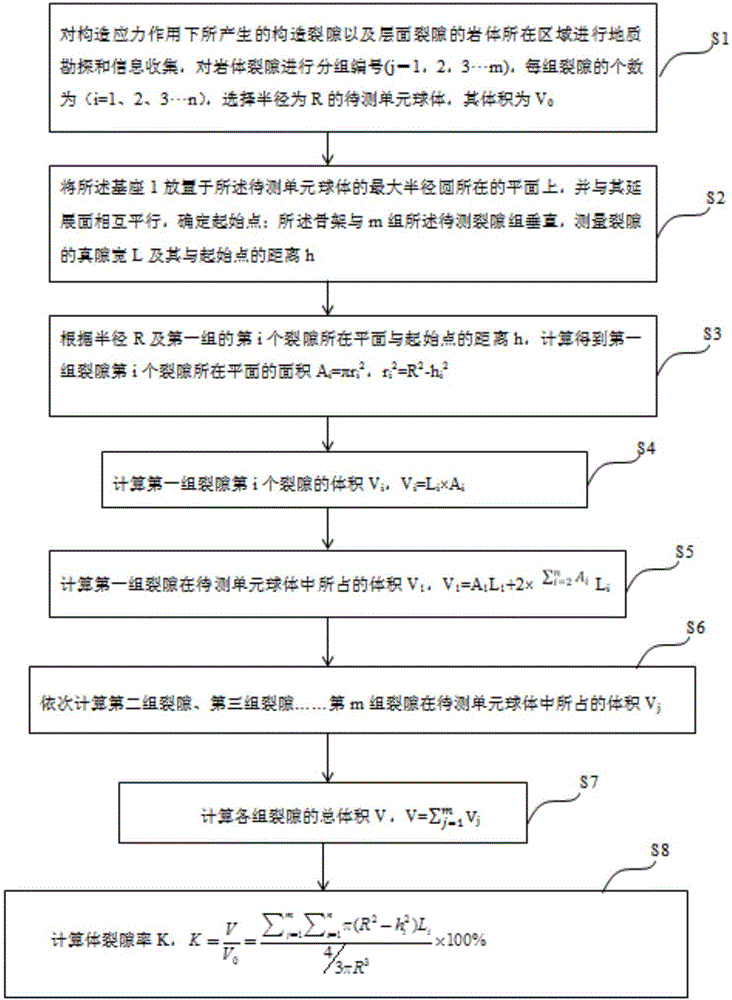

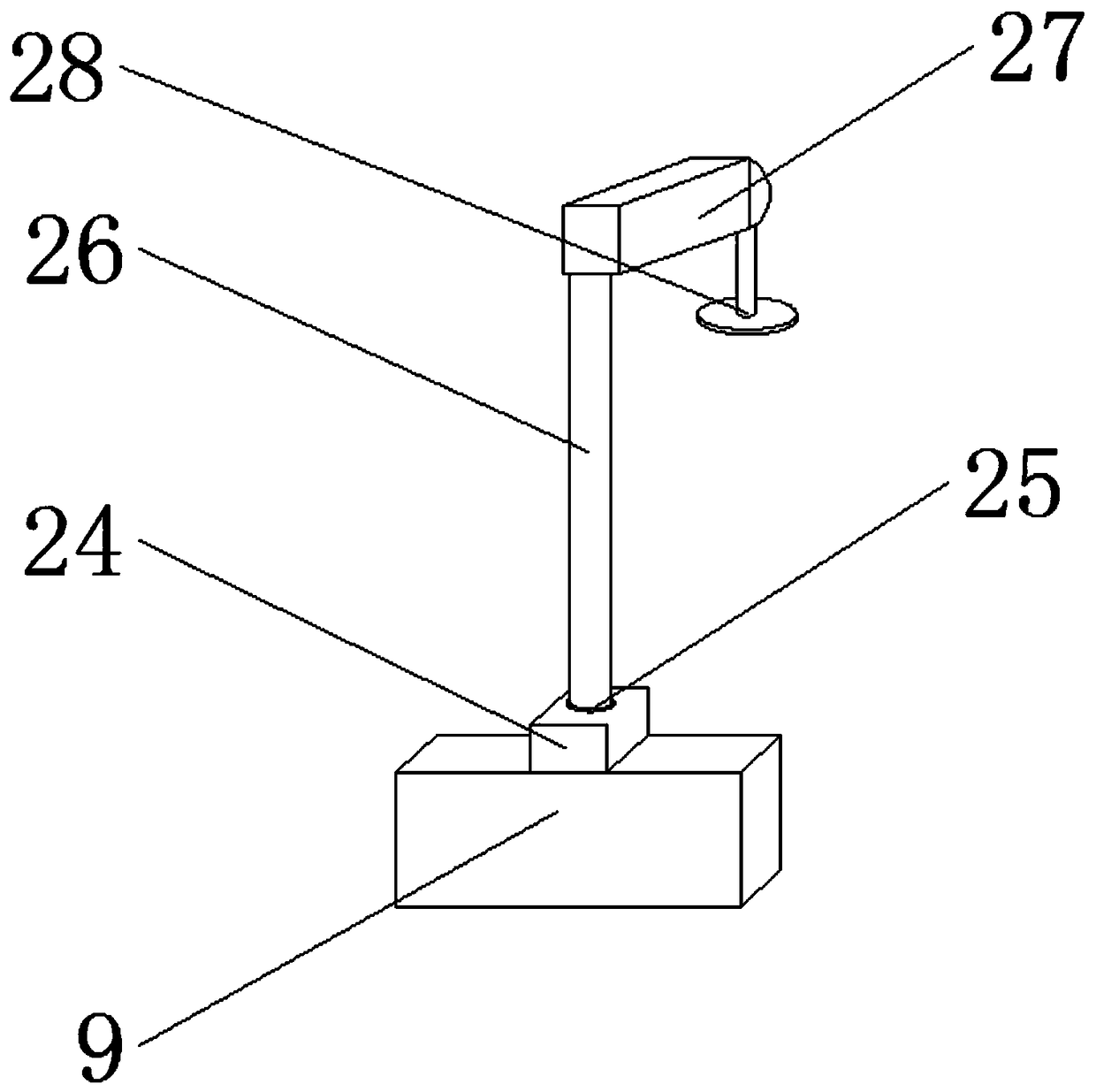

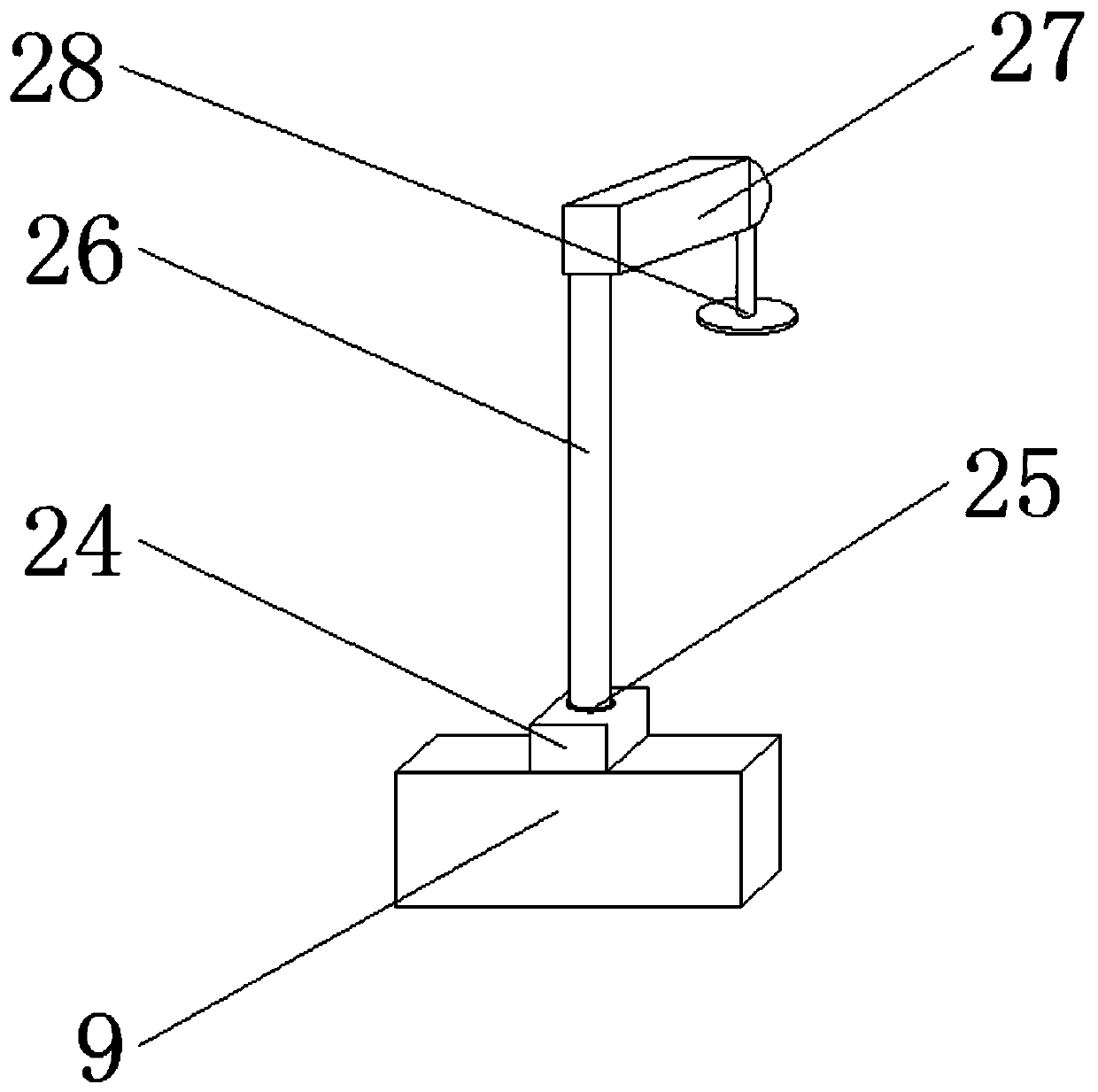

Instrument and method for measuring volume fissure rate of rock

ActiveCN107436119AReduce volumeAccurate measurement dataVolumetric dimension measurementsLight beamMechanical engineering

The invention discloses an instrument and method for measuring the volume fissure rate of rock, and the instrument comprises a substrate, a skeleton, a fissure aiming device, a fixing device, and a hand-cranking device. A screw rod rotates under the action of the hand-cranking device, and drives the fissure aiming device on the fixing device to move up and down through threaded transmission. During measurement, the substrate is placed on the rack, and a plane where the substrate is parallel to an extending plane of fissures of a fissure group of a to-be-detected rock. A plane where a laser beam and a zero scale line on a calibrated scale on a side surface of the substrate is parallel to an extending plane of fissures of the fissure group of the to-be-detected rock, and one fissure of the fissure group of the to-be-detected rock is taken as the start point for the measurement from the bottom to the top. The true fissure width of each fissure in the fissure group and the distance between each fissure and the start point are recorded, wherein the measured fissure width is the true fissure width. The measurement data is accurate, and provides parameters for the calculation of the volume fissure rate of rock. The instrument is smaller in size, is light, and is portable. The application method is simple, so the instrument is suitable for the measurement of the volume fissure rate of outdoor rocks.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

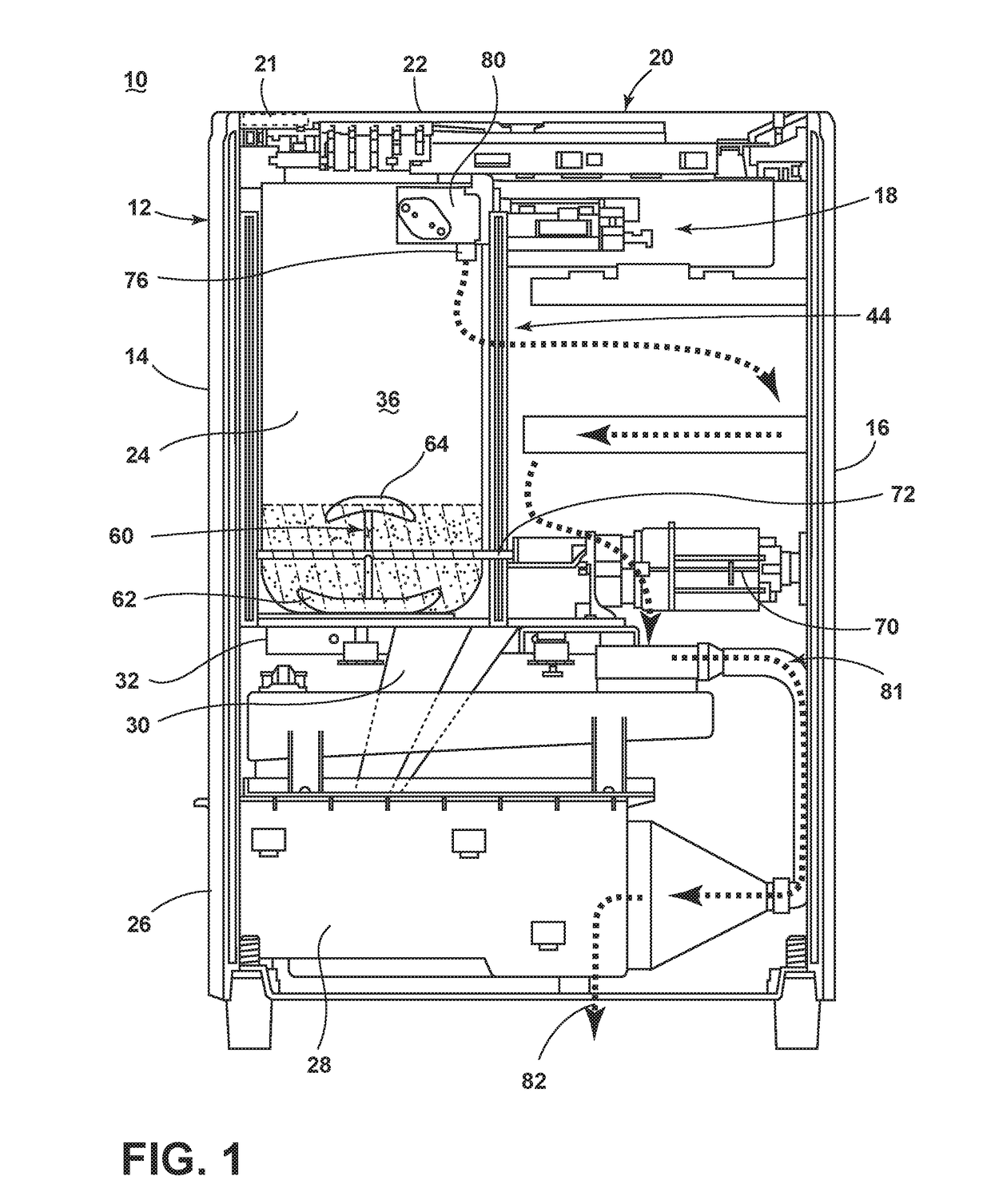

Cable-based measuring system

ActiveUS9541422B2Length measurement chainsUsing electrical meansMeasurement deviceDimension measurement

The present invention extends to methods, systems, apparatus, and computer program products related to a cable-based measuring system. The cable-based measuring system includes a cable, comprising an inner cable member configured to move linearly within an outer cable housing. The measuring system also includes a measuring device configured to generate measurement information regarding movement of the inner cable member relative to the outer cable housing using one or more encoders. A computer system receives the measurement information from the measuring device. The measurement information indicates length as a function of time, and represents three orthogonal dimensional measurements of a three-dimensional object. Based on the measurement information, the computer system identifies a length of each dimensional measurement, including a length, a width, and a height of the three-dimensional object. The computer system then initiates creation of a box template sized to accommodate the three-dimensional object and / or updates a database.

Owner:PACKSIZE

Vehicle compartment volume measurement system frame

ActiveCN106289057ASimple designEasy to operateUsing optical meansVolumetric dimension measurementsMeasurement costCoupling

The invention discloses a vehicle compartment volume measurement system frame including a base, a measurement control cabinet, and two rows of parallelly and symmetrically arranged columns, the bottom ends of the columns are vertically fixed on the base, the inner sides of the top ends of the two adjacent columns of each row are successively connected and fixed through a first groove type linear guide rail and a second groove type linear guide rail, the grooves of the first groove type linear guide rail and the second groove type linear guide rail are provided with tooth bars, a walking mechanism is vertically arranged between the first groove type linear guide rail and the second groove type linear guide rail, the walking mechanism includes a double-shaft motor, a coupling shaft, and gears, the double-shaft motor is fixedly arranged in the center of the walking mechanism, the output shafts of the two ends of the double-shaft motor are connected with the gears through the coupling shaft, and the gears are engaged with the tooth bars. The measurement support can rapidly and accurately measure the volume of goods within the vehicle compartment, and is low in measurement cost and small in error.

Owner:GUANGXI WODEKEJI TECH

Product quality quick detection tool

InactiveCN105486192AQuick filterImprove work efficiencyVolumetric dimension measurementsCost savingsEngineering

Owner:海宁市飞腾电子有限公司

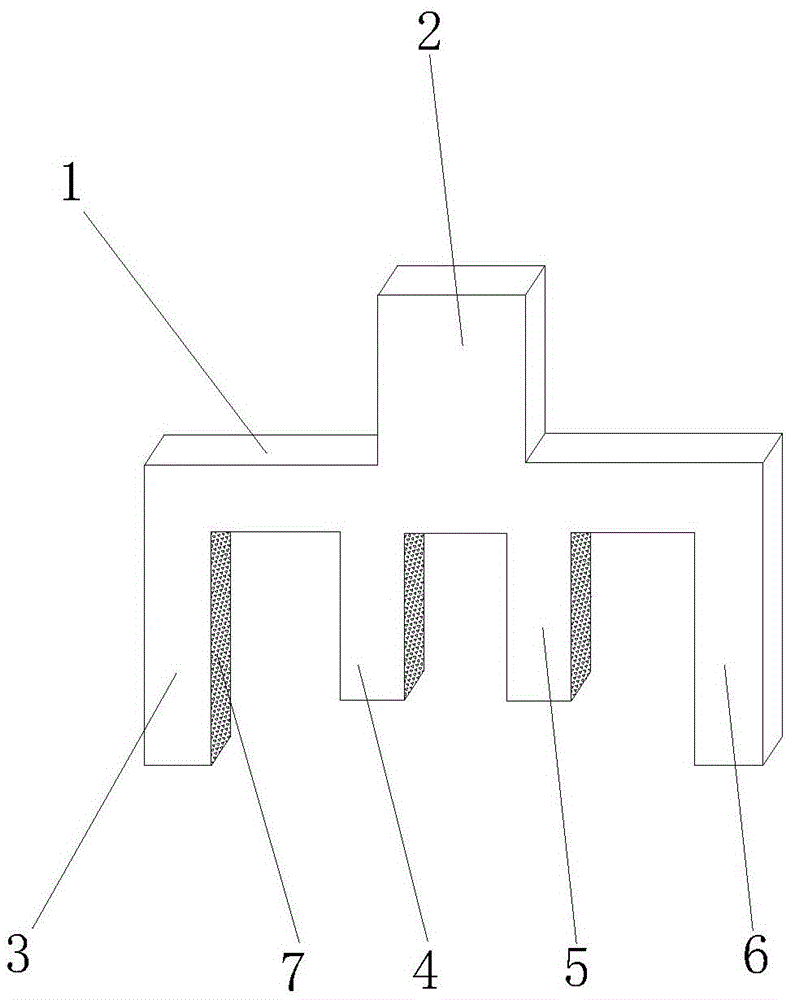

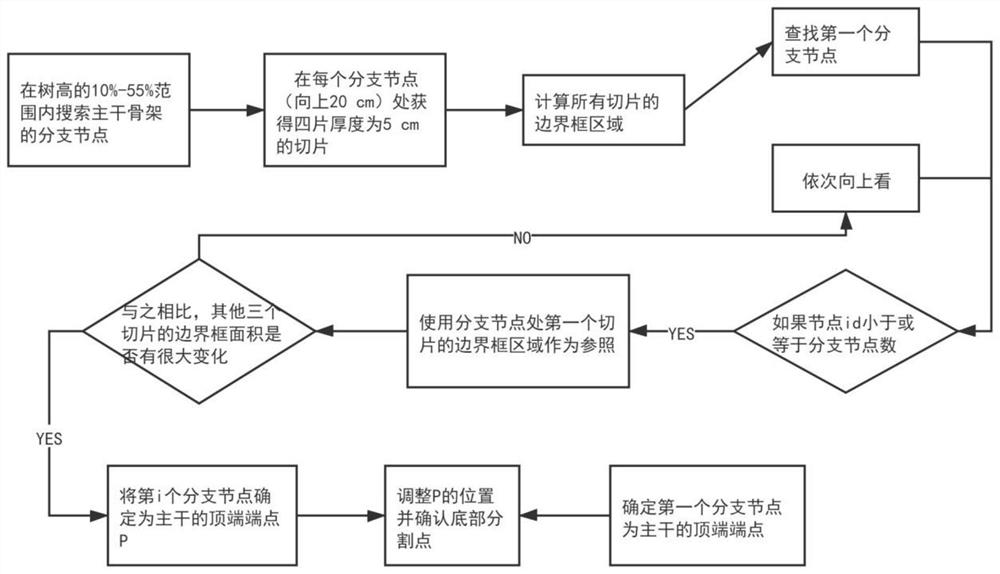

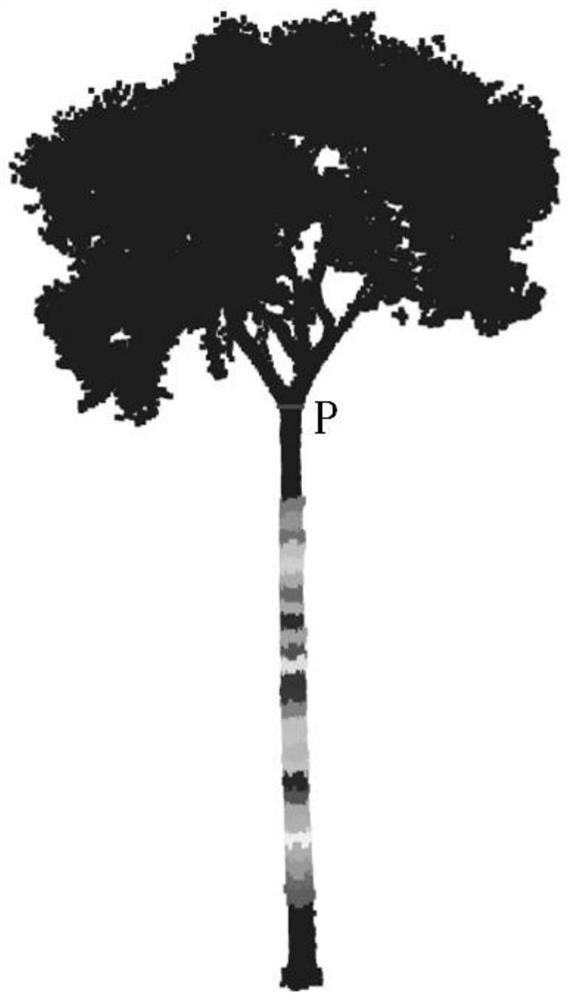

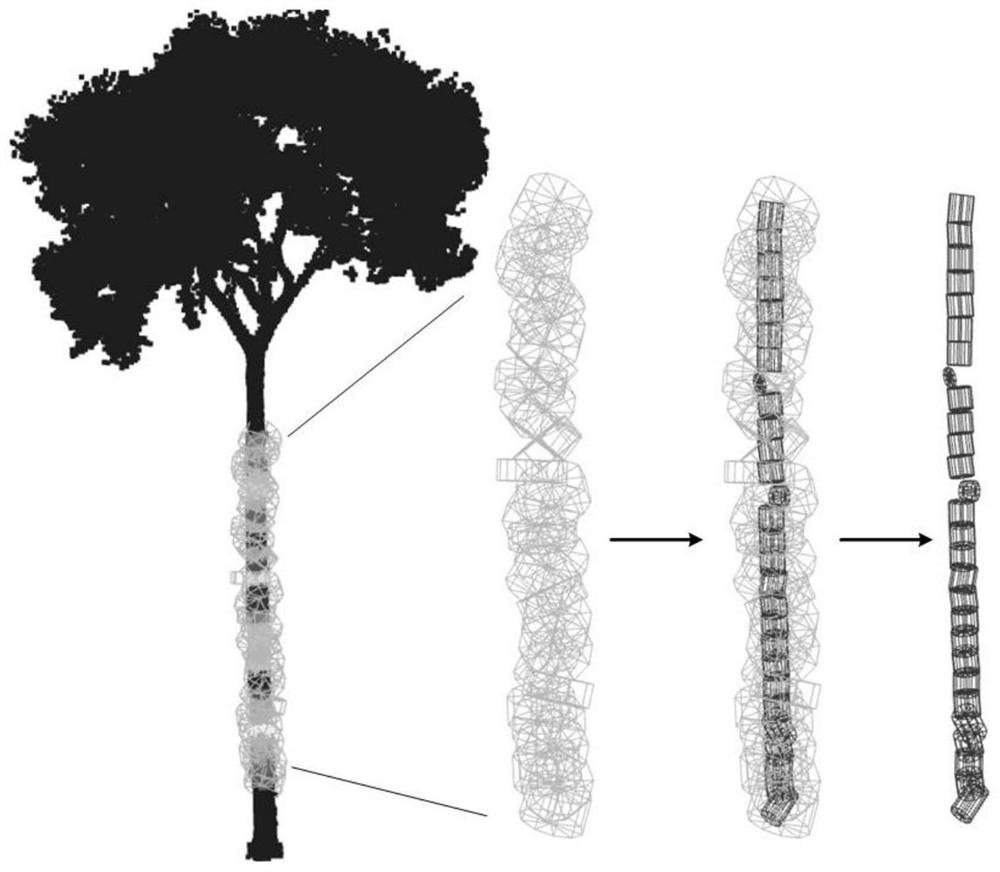

Low-cost tree structure automatic reconstruction method for lossless estimation of standing wood volume

PendingCN114136208AAccurately find the high position under the branchLow costPicture taking arrangementsCharacter and pattern recognitionTree trunkAgricultural engineering

The invention discloses a low-cost tree structure automatic reconstruction method for lossless estimation of standing wood volume, and particularly relates to a method for reconstructing a tree three-dimensional model based on terrestrial photogrammetry point cloud. The invention provides a standing wood volume estimation method based on terrestrial photogrammetry point cloud in order to reduce the cost of trunk volume estimation and under the condition that trees are not damaged by aiming at the defects and deficiencies of existing standing wood volume estimation, and the method is used for reconstructing a three-dimensional geometric structure of the trees and extracting the trunk volume. And a more economical method is provided for lossless estimation of the standing wood volume. The research objectives of the invention comprise: (1) opening AdQSM, and developing an automatic modeling method of AdQSM, which is beneficial for more people to use; and (2) a novel low-cost tree structure modeling technology is developed.

Owner:BEIJING FORESTRY UNIVERSITY

Object dimensioning apparatus, systems and related methods

Owner:QUANTRONIX

Intelligent sorting device for logistics transportation

ActiveCN108816781AConvenient volume measurementEasy to separate statisticsVolumetric dimension measurementsSortingVolume measurementsLogistics management

The invention discloses an intelligent sorting device for logistics transportation. The intelligent sorting device comprises a workbench. A transmission table is fixed to the upper end of the workbench. A suction processor is connected to the middle of the front end of the workbench, a supporting base is welded to the upper end of the suction processor, a lifting port is formed in the upper end ofthe supporting base in an embedded mode, the length and width of a product can be scanned and measured through a measuring area in a measuring plate, safe storage of the product is facilitated, the height of the product can be measured through six height measuring rods which are evenly distributed on the front side and the rear side of the upper end of the measuring plate, therefore, volume measurement of the whole product is facilitated, a non-fragile product number display screen with the thickness being 1 cm is utilized for being bonded with a non-fragile product storage box through strongglue, the number of non-fragile products can be displayed for facilitating separated statistics, and number sensing plates in a fragile product sorting ladder are utilized and evenly distributed in the fragile product sorting ladder.

Owner:广州恒岩科技有限公司

An intelligent sorting device for logistics transportation

ActiveCN108816781BConvenient volume measurementEasy to separate statisticsVolumetric dimension measurementsSortingVolume measurementsLogistics management

The invention discloses an intelligent sorting device capable of realizing classified statistics for logistics transportation. The device comprises a worktable; a transmission table is fixed at the upper end of the worktable; an object sucking treater is connected to the middle of the front end of the worktable; a support base is welded at the upper end of the object sucking treater; a lifting port is embedded in the upper end of the support base; through a measuring area in a measuring plate, the lengths and the widths of objects can be scanned and measured to achieve the object storage safety; six height measuring rods are uniformly distributed on the front and back sides of the upper end of the measuring plate for measuring the heights of the objects to achieve the volume measurements of the whole objects; a non-fragile product number display screen is used; the thickness of the non-fragile product number display screen is 1 cm; the non-fragile product number display screen is bonded with a non-fragile product storage box through super glue, and can display the number of non-fragile products to achieve separated statistics; and number induction plates in fragile product steps are used, and are uniformly distributed in the fragile product steps.

Owner:广州恒岩科技有限公司

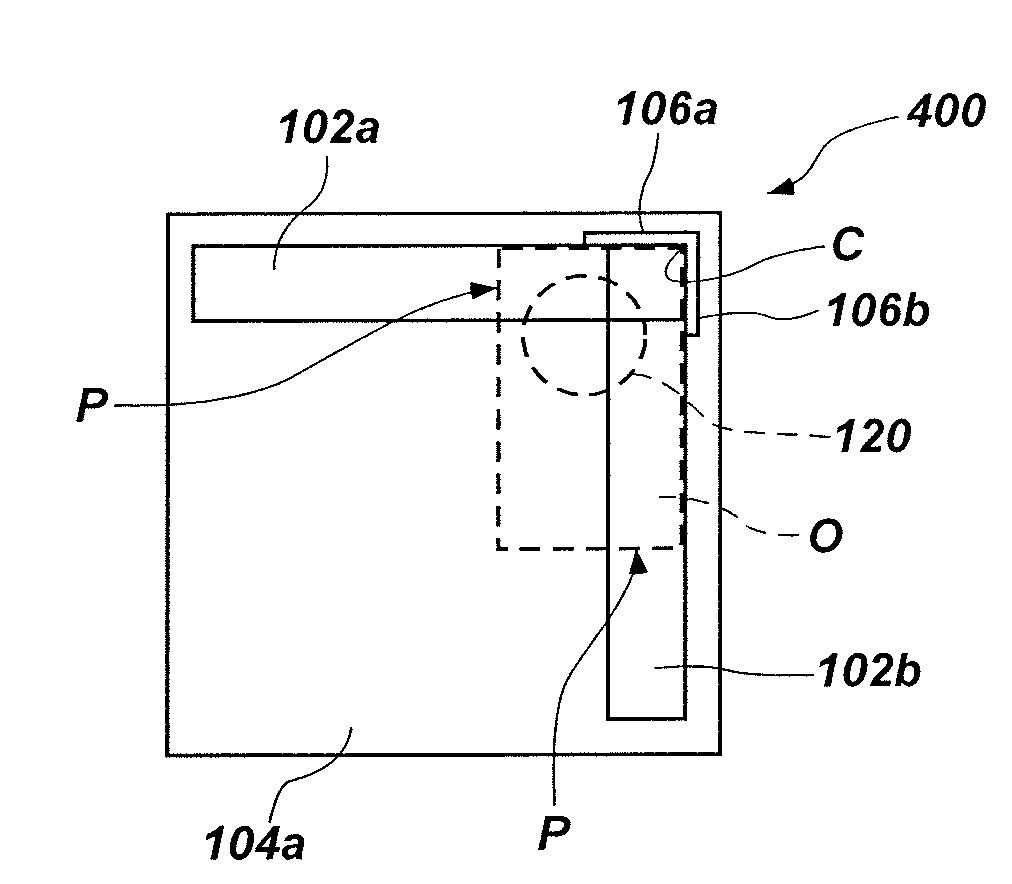

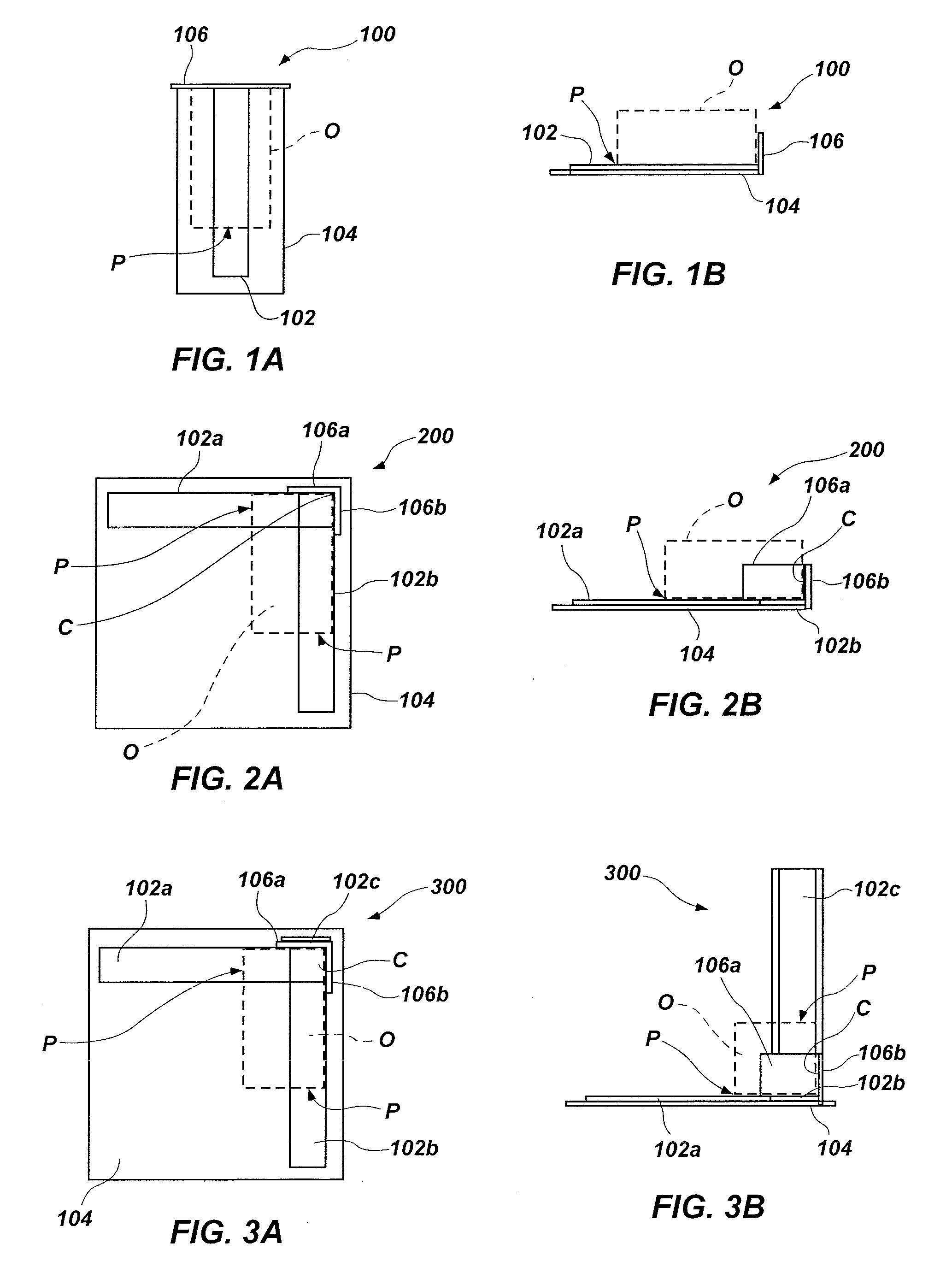

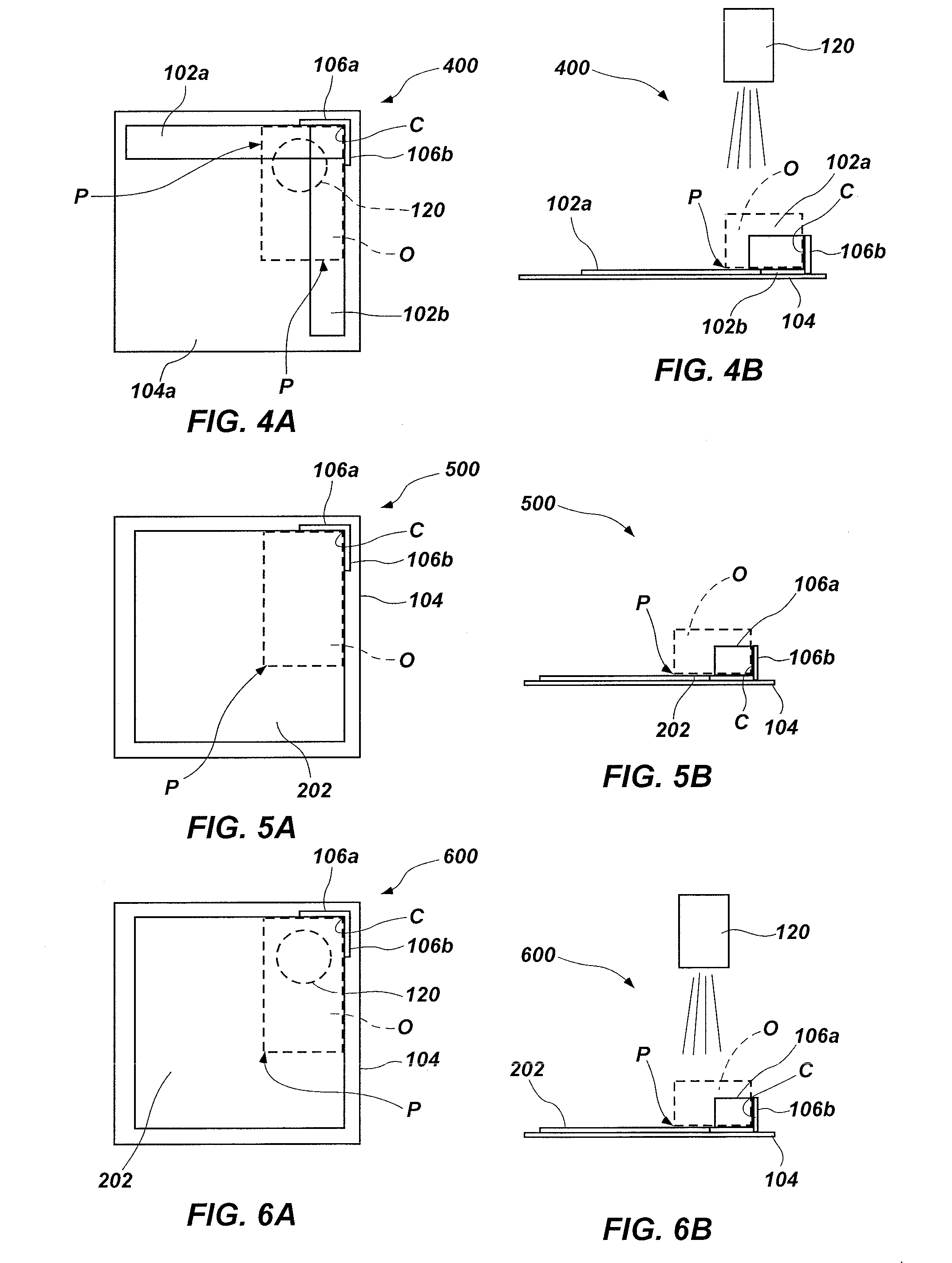

Cable-Based Measuring System

The present invention extends to methods, systems, apparatus, and computer program products related to a cable-based measuring system. The cable-based measuring system includes a cable, comprising an inner cable member configured to move linearly within an outer cable housing. The measuring system also includes a measuring device configured to generate measurement information regarding movement of the inner cable member relative to the outer cable housing using one or more encoders. A computer system receives the measurement information from the measuring device. The measurement information indicates length as a function of time, and represents three orthogonal dimensional measurements of a three-dimensional object. Based on the measurement information, the computer system identifies a length of each dimensional measurement, including a length, a width, and a height of the three-dimensional object. The computer system then initiates creation of a box template sized to accommodate the three-dimensional object and / or updates a database.

Owner:PACKSIZE LLC

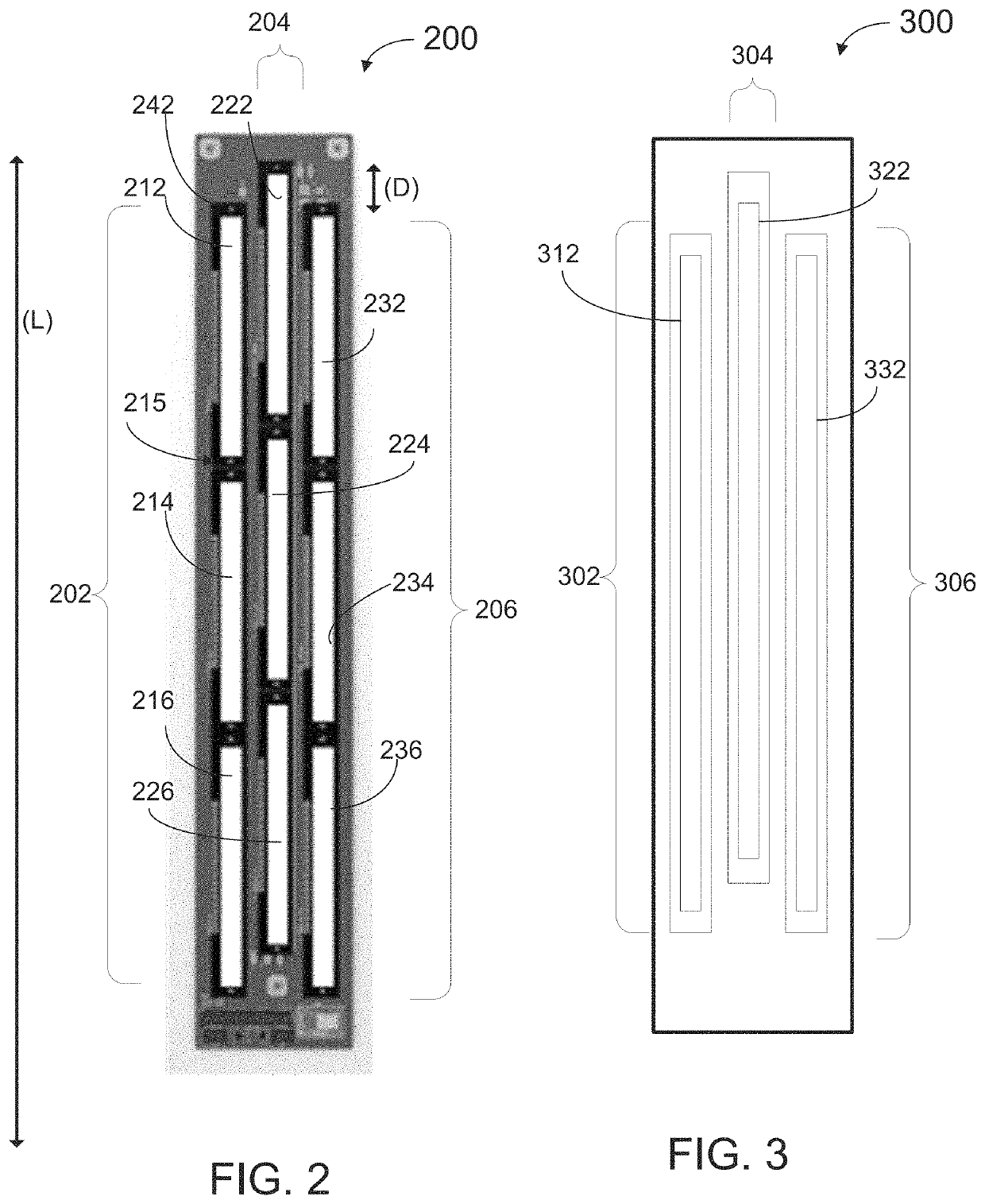

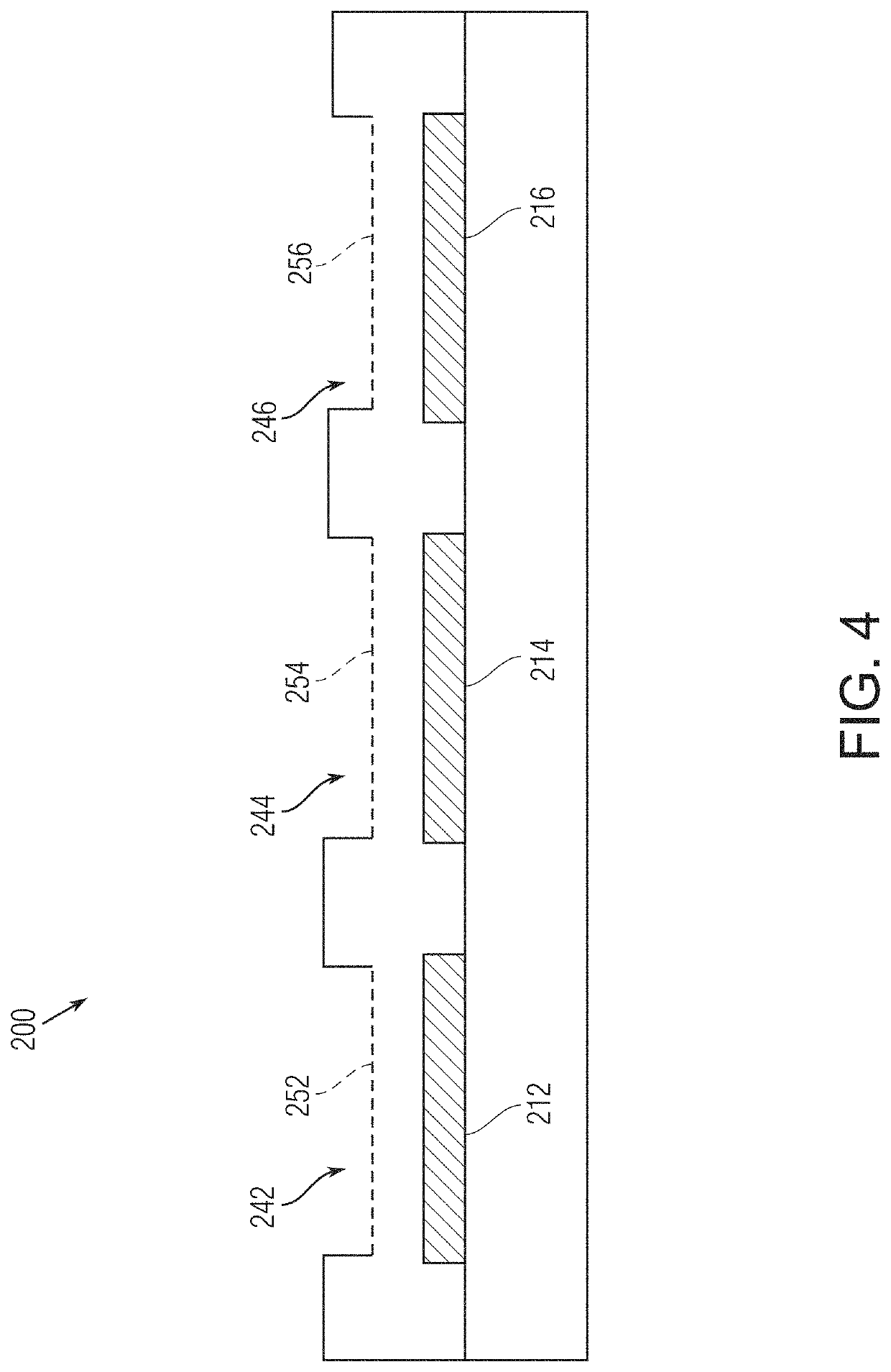

Sensor device for distance offset measurements

ActiveUS10900776B2Reduce the angle of incidenceReduce the angleMeasuring circumferenceUsing optical meansMicrocontrollerAngle of incidence

A sensing device for measuring an offset along a longitudinal axis comprises a housing including a plurality of slots, two or more arrays of optical sensors aligned along the longitudinal axis, at least one of the arrays being offset along the longitudinal axis with respect to the other arrays and a microcontroller coupled to the two or more arrays of optical sensors and configured to determine a positional offset along the longitudinal axis at which light is detected by at least one of arrays of optical sensors. In some embodiments, each of the optical sensors of the arrays are positioned within the housing underneath one of the plurality of slots to reduce an angle of incidence of radiation received.

Owner:SAUDI ARABIAN OIL CO

Worn banknote proportional contrast scale

InactiveCN110260746AEasy to fix and stableGuaranteed accuracyCoin/currency accepting devicesVolumetric dimension measurementsEngineering

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com