Device and method for measuring volume expansion characteristics of material under tensile load

A technology of volume expansion and measuring device, applied in the direction of measuring device, analyzing material, strength characteristics, etc., can solve the problems of inability to accurately determine the time and displacement point of sample stretching, and it is difficult to ensure the volume compensation rod, so as to ensure the measurement Traceability, ensure accuracy, and avoid the effect of gas state changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

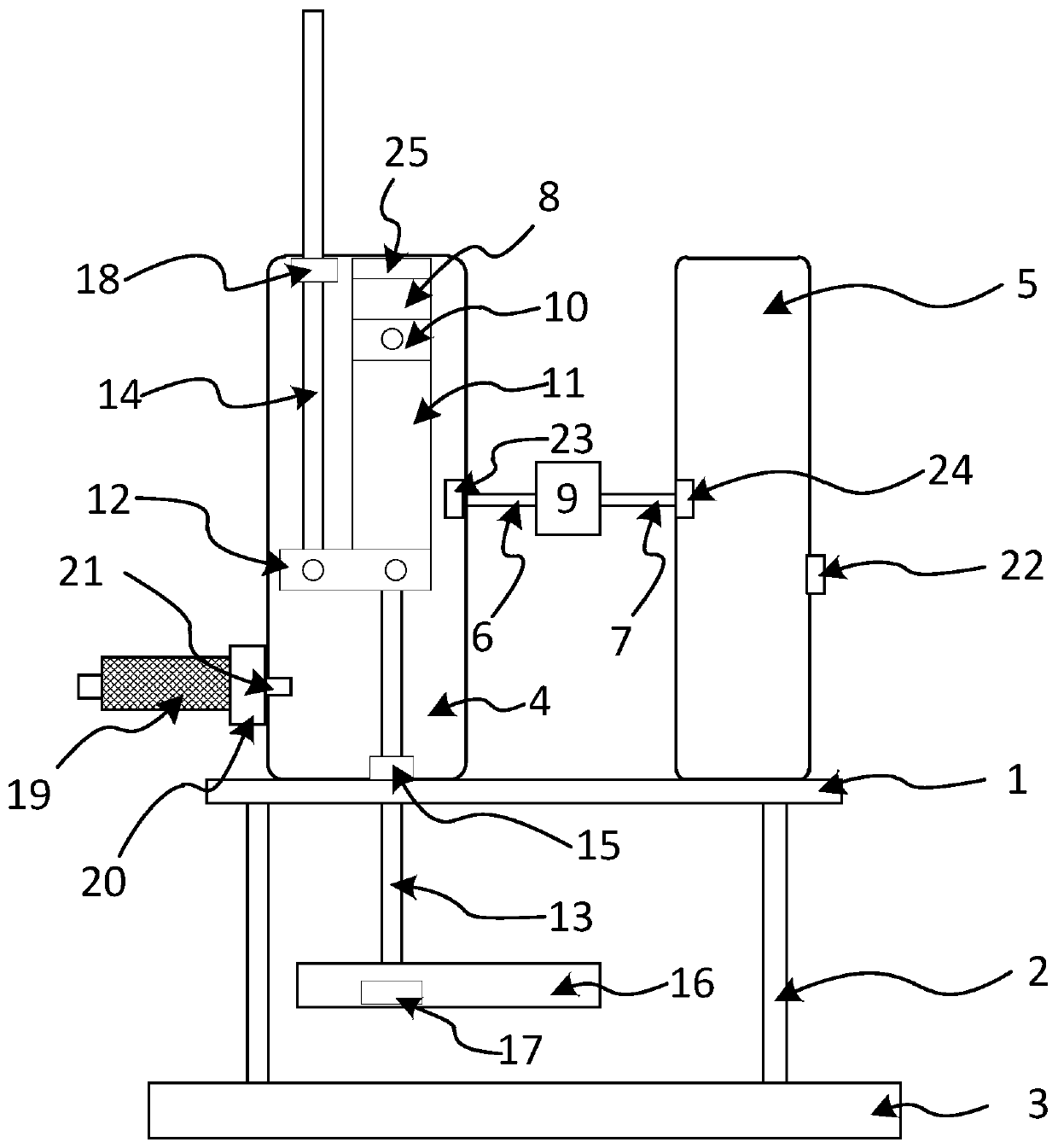

[0030] Such as figure 1 As shown, a measuring device for the volume expansion characteristics of materials under tensile load is characterized in that it includes a platform 1, which is installed on the base 3 of the tensile testing machine through the support column 2, and the test chamber 4 and the reference chamber 5 are fixed on the platform 1 , the top of the test chamber 4 fixes the mounting seat 25, the force sensor 8, and the upper fixture 10 sequentially from top to bottom. The upper end of the stretching rod 13 and the lower end of the compensating rod 14 are connected and fixed. The stretching rod 13 passes through the test chamber 4 under the stretching rod mount 15, and its lower end is connected and fixed with the tensile test motorized crossbeam 16. The displacement is installed on the crossbeam 16. The displacement sensor 17 on the measurement; the compensation rod 14 passes through the test chamber 4 on the compensation rod mount 18; the screw micrometer 19 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com