Pit-digging volume detection device and method for detecting subgrade compaction degree by pit-digging method

A detection device and a technology of compaction degree, which are applied in the direction of measuring device, volume dimension measurement, and optical device, etc., can solve the problem of high work intensity, and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

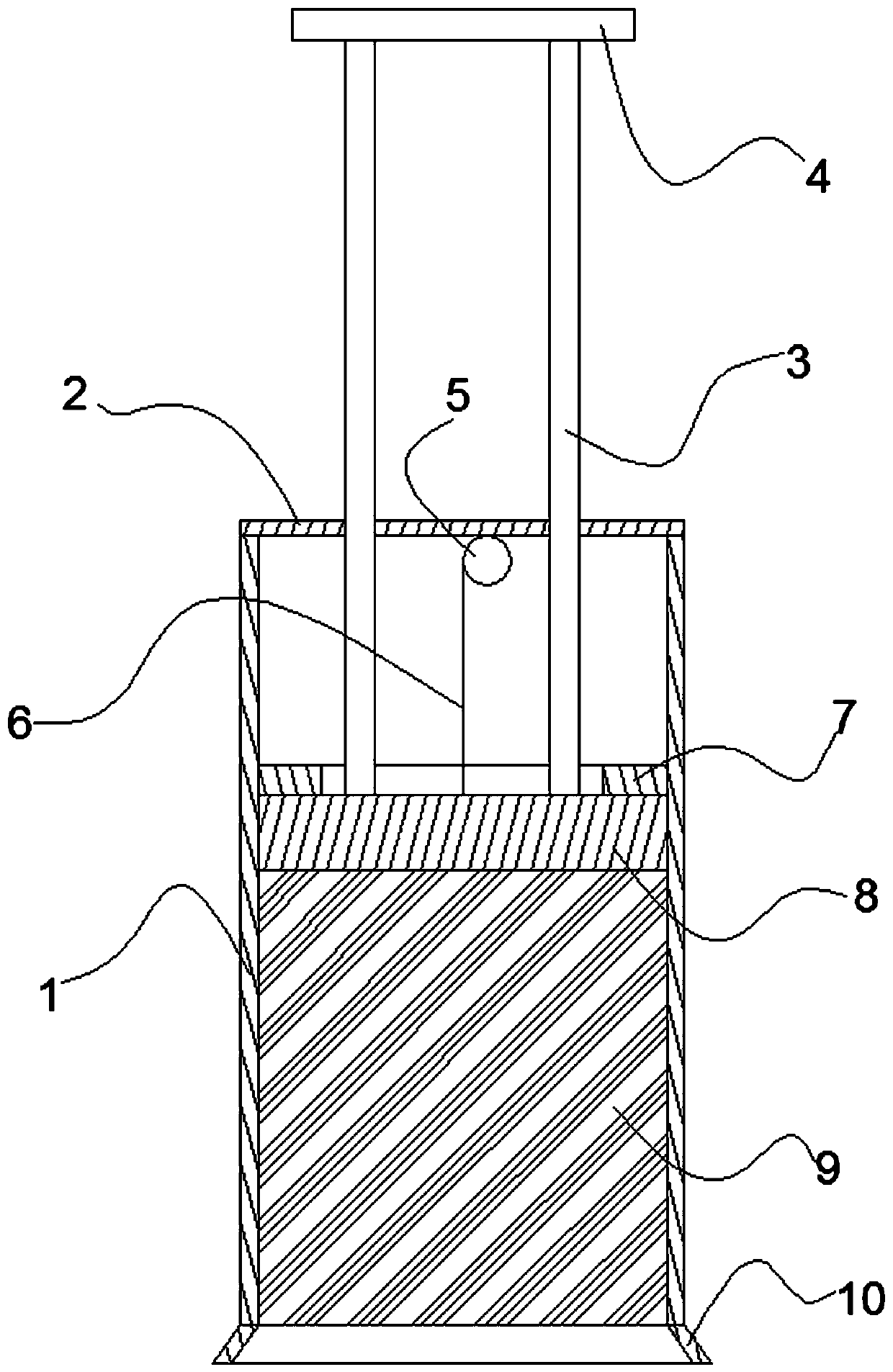

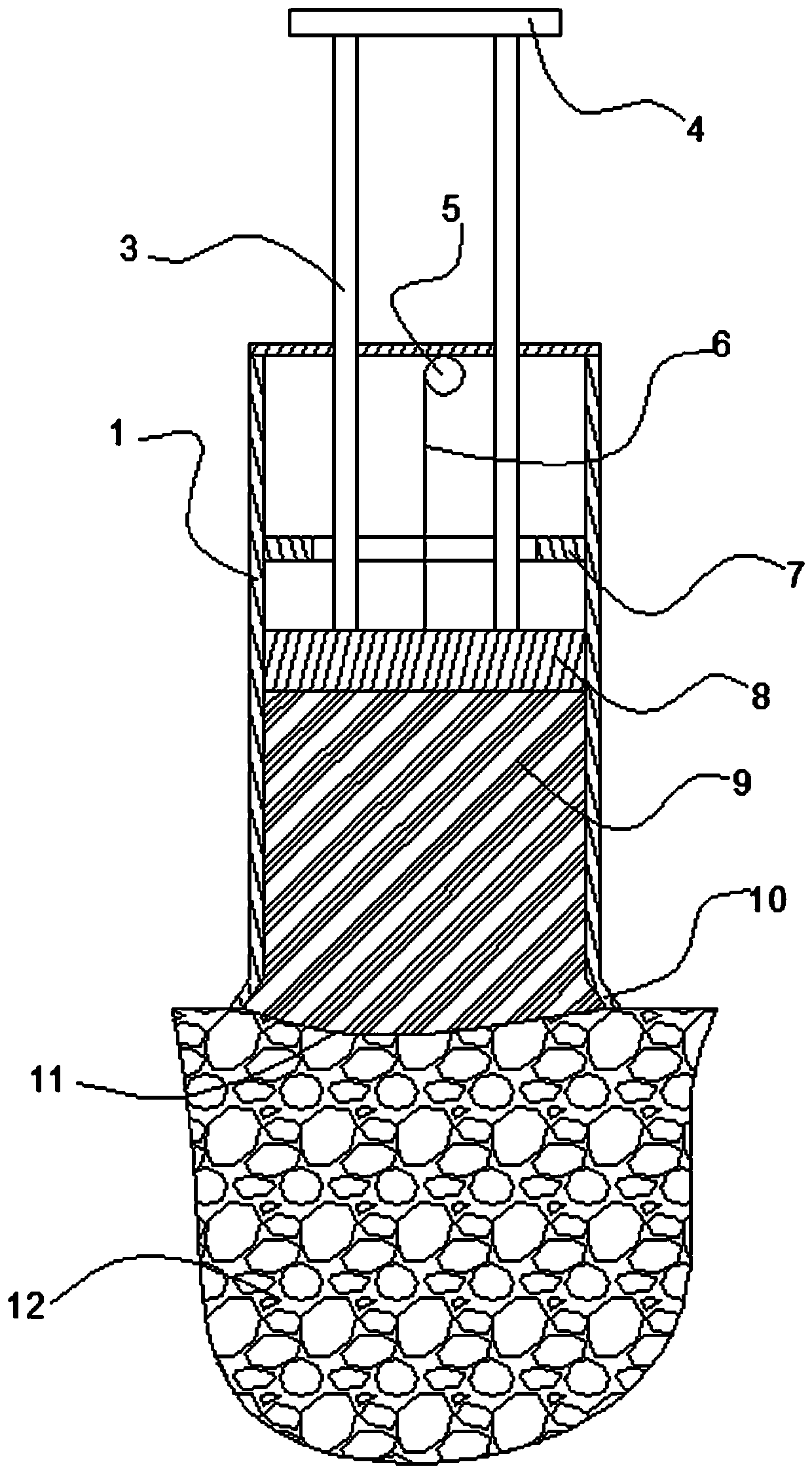

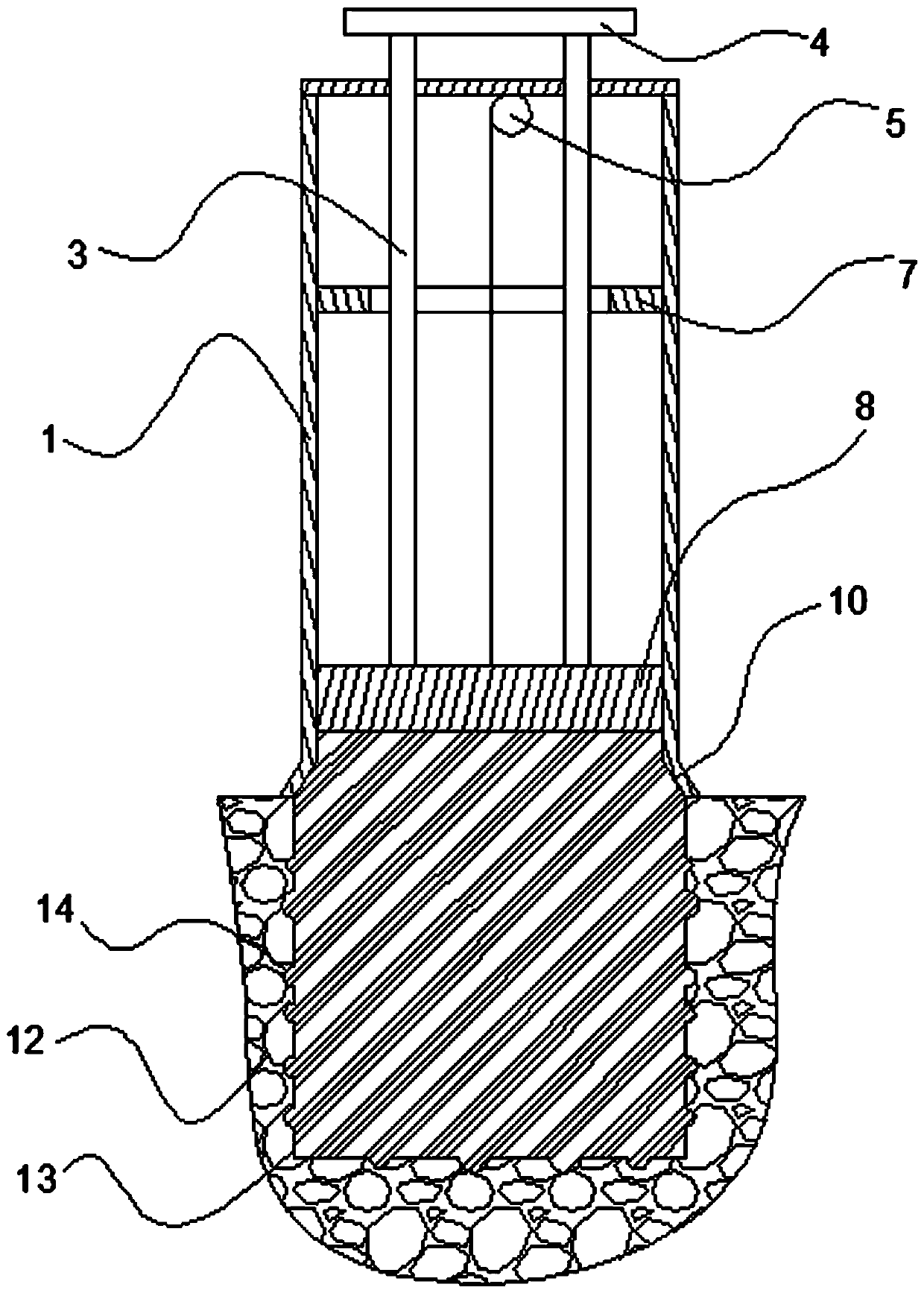

[0019] Embodiments of the digging method road surface digging volume detection device in the present invention are for example Figure 1~3 Shown: includes a piston barrel 1 with a cylindrical inner cavity, a barrel top 2 is arranged on the top of the piston barrel 1, a piston 8 is installed for guiding and moving inside the piston barrel 1, and a piston push rod 3 is connected to the upper end of the piston, and the piston push rod The upper end of 3 is protruded from the piston barrel, and the protruding end of the piston push rod is provided with a handle 4 for the operator to hold and operate.

[0020] The lower end of the piston is fixed with a solid flexible body 9 for being pushed and moved by the piston to fill the corresponding road surface 11 or detection hole 13 to be dug through the bonding structure. The solid flexible body 9 is a cylinder with the same outer diameter as the inner diameter of the piston barrel 1 structure, the solid flexible body 9 is made of silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com