Rapid measuring mechanism of size of vehicle compartment and construction method thereof

A technology of measuring mechanism and construction method, applied in the field of vehicle compartment volume measurement, can solve the problems such as difficult control of vehicle running speed, low efficiency, measurement error, etc., and achieve the effect of simple and easy construction method, high safety, and low measurement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

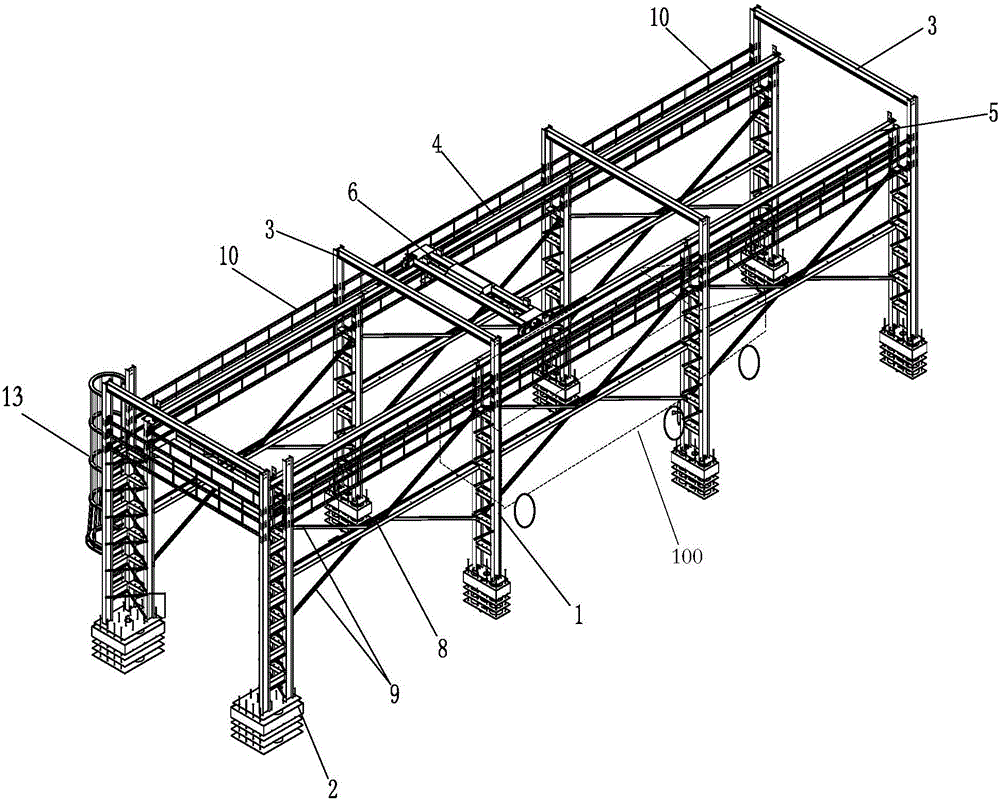

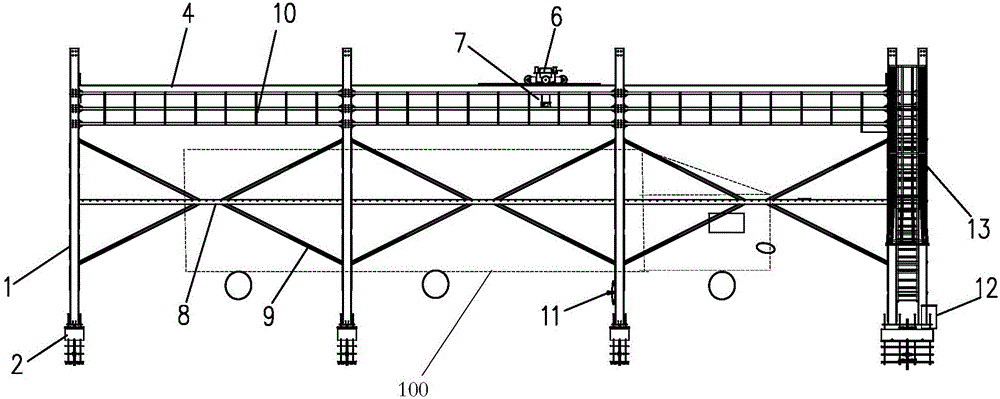

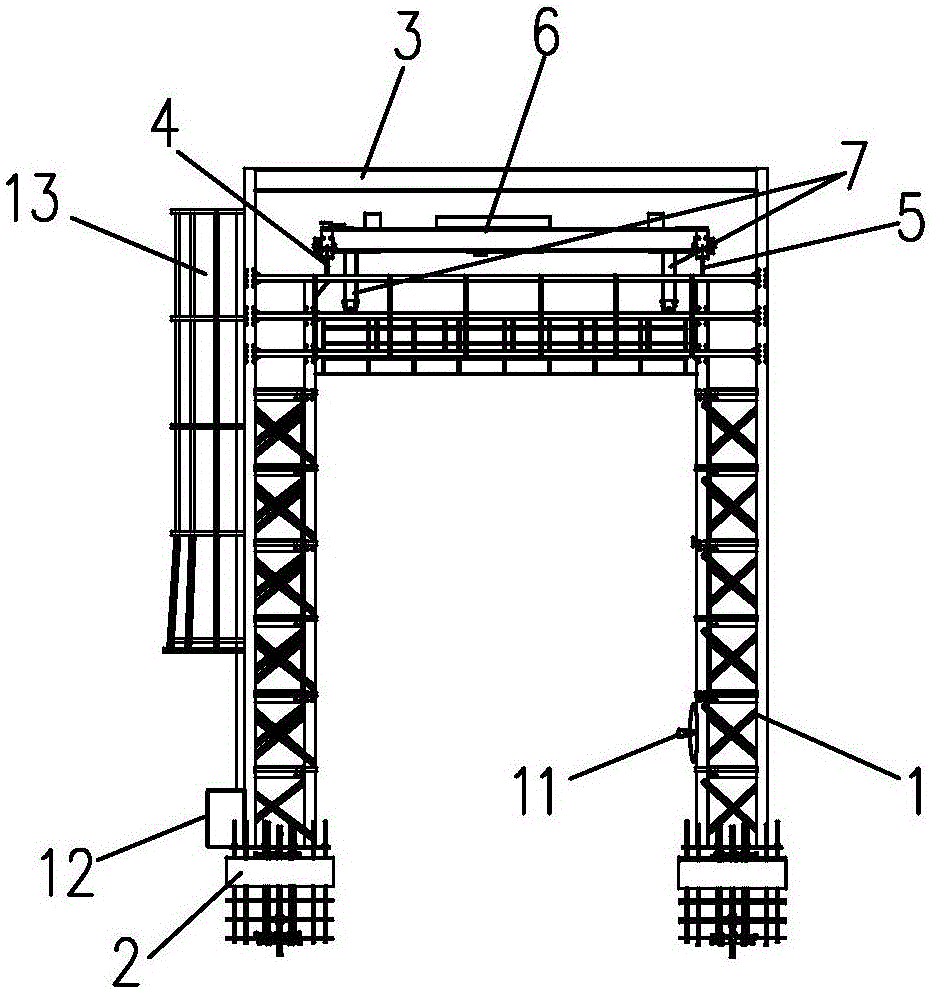

[0033] Such as figure 1 , figure 2 , image 3 with Figure 4As shown, according to a rapid measurement mechanism for vehicle compartment volume of the present invention, the measurement mechanism adopts a combined square body structure frame, including a fixed pier 2, a measurement control box 12 and two rows of columns 1 arranged in parallel and symmetrically. The pier 2 includes an embedded part 20 and a positioning column 200 arranged at the center of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com