Apparatus for vertical metal can capacity measurement

A capacity measurement and metal tank technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of heavy workload, high difficulty, and great influence on the capacity of metal tanks, etc., to achieve continuous measurement, increase suction, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

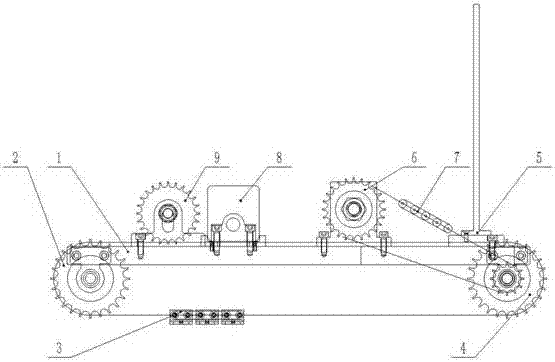

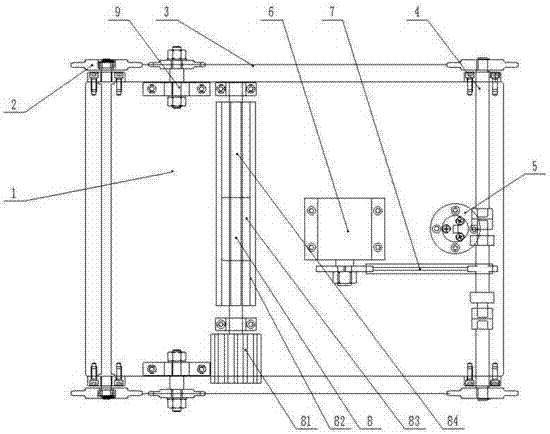

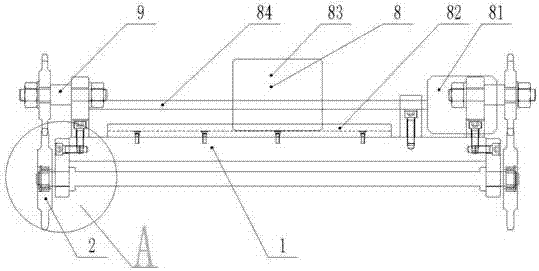

[0035] Embodiment 1: as figure 1 As shown, the platen 1 is a mounting plate with a certain thickness, and the right side of the mounting plate is fixed with a scale 5, which is made of elastic material and can be bent; figure 2 , image 3 As shown, the sliding adjustment mechanism 8 is installed in the middle of the platen 1. The sliding adjustment mechanism 8 includes an adjustment motor 81, a slideway 82, a slider 83, and a screw rod 84. The adjustment motor 81 can realize remote control of positive and negative rotation. The slideway 82 And the adjustment motor 81 is fixed in a straight line along the short side of the platen 1, the slide block 83 is located on the slideway 82, and the screw mandrel 84 is connected by the adjustment motor 81 and is movably connected with the slide block 83 by threads; figure 1 , Figure 5 As shown, the driven mechanism 2 is located on the left side of the platen 1. The driven mechanism 2 includes a driven shaft seat 21, a driven sprocket...

Embodiment 2

[0036]Embodiment 2: the difference between this embodiment and embodiment 1 is: the scale 5 is divided into a scale upper section 51 and a scale lower section 54, and the scale upper section 51 and the scale lower section 54 are flexibly connected by a hinge shaft 53 and tensioned by a tension spring 52.

[0037] The device is adsorbed on the tank wall of the metal tank to be tested by the adsorption mechanism, and the driving mechanism is driven by the remote control power mechanism to make the device climb along the tank wall of the metal tank. The device stops after reaching the measurement point, and is observed and recorded. The reading of the scale can be used for subsequent numerical integration; by installing a sliding adjustment mechanism and adjusting the position of the slider, the center of gravity of the device will be offset. When the direction of the device changes during the crawling process of the tank wall, the center of gravity will Use the torque generated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com