Wall-climbing robot used for capacity verification of vertical metal tank

A technology for a wall-climbing robot and a metal can, which is applied in the field of wall-climbing robots, can solve the problems of high labor intensity, unstable measurement accuracy and high risk, and achieves the effect of improving labor intensity and avoiding the inability to measure and adjust the suction force in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

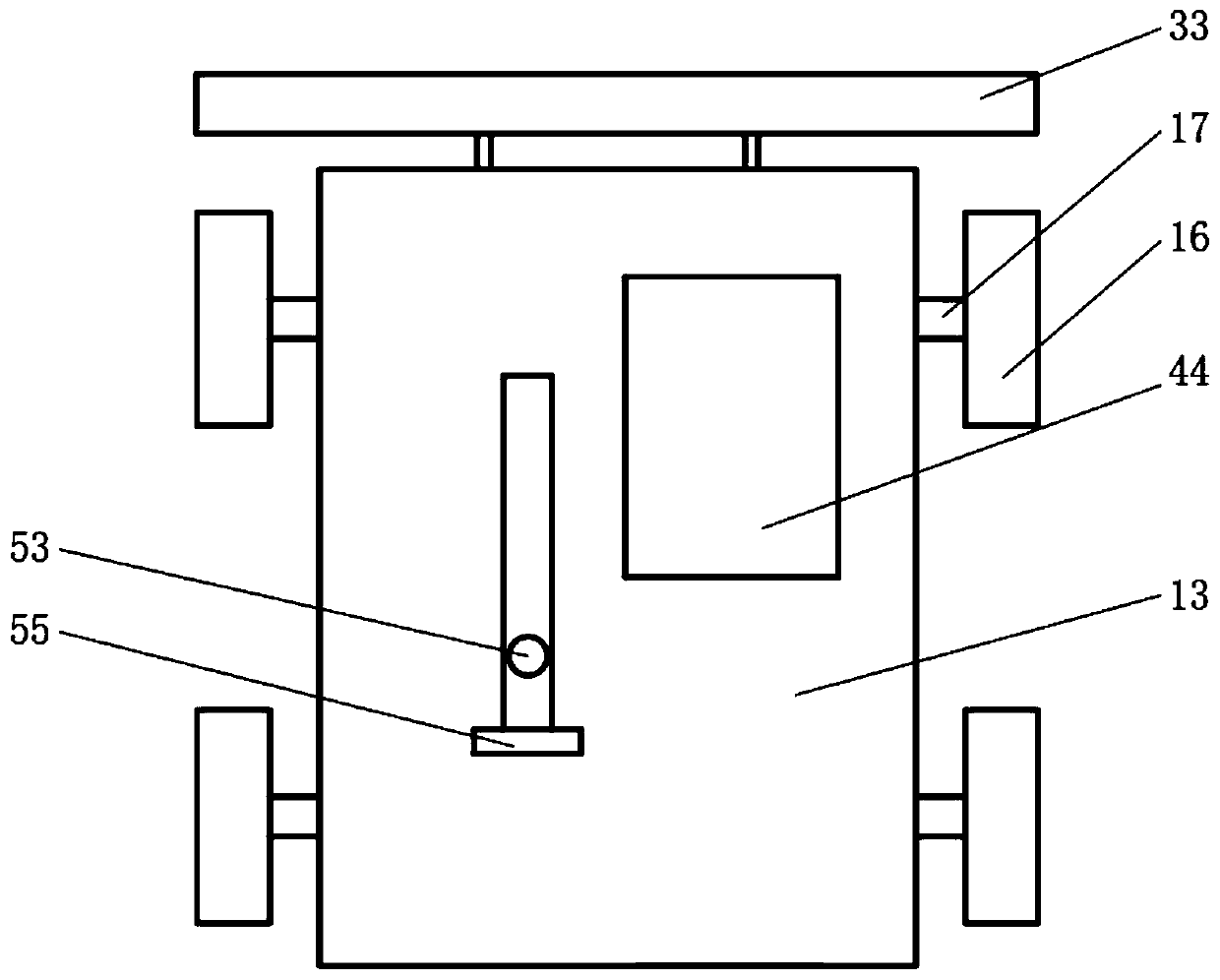

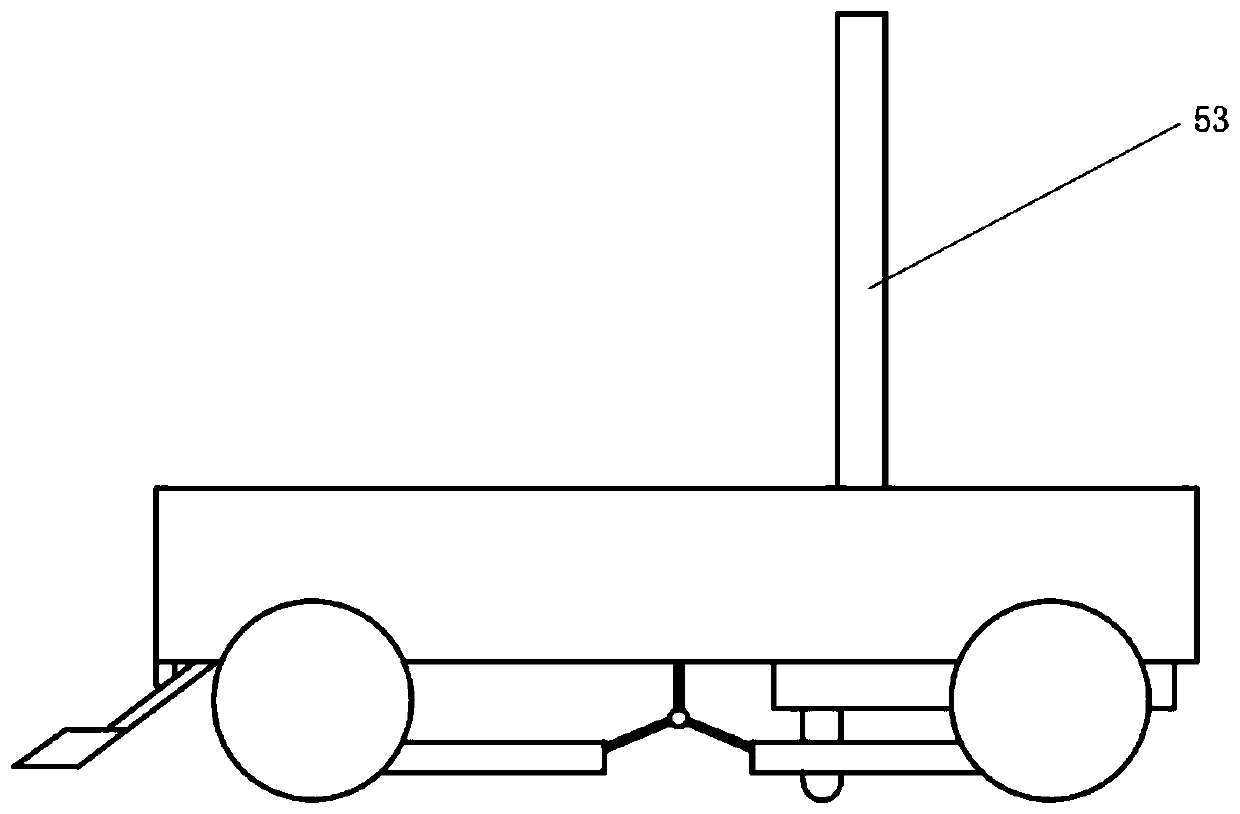

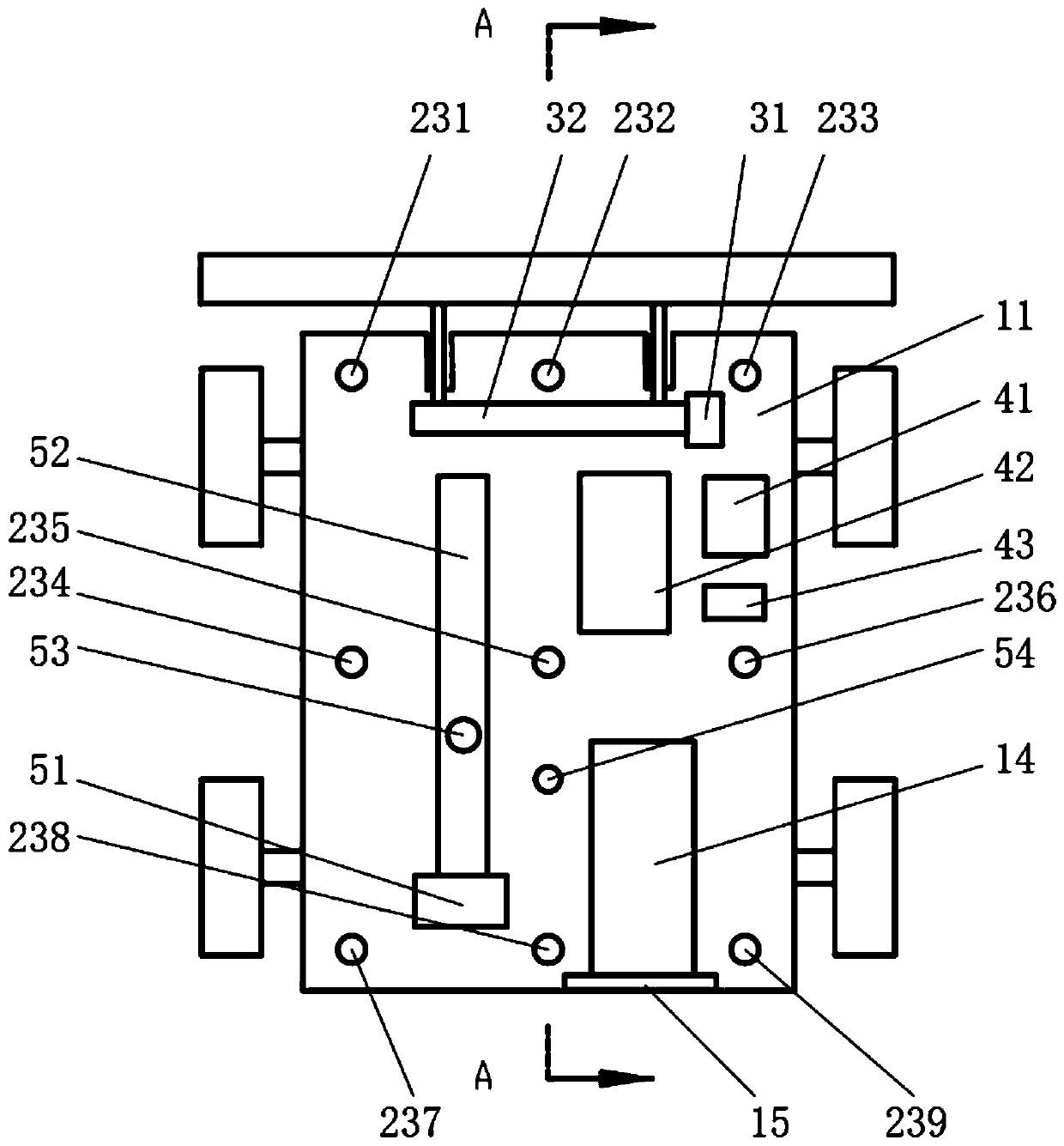

[0046] see Figure 1 to Figure 5 , the wall-climbing robot used for capacity verification of vertical metal tanks in this embodiment includes a robot body, an adsorption unit, a rust removal unit, a control unit, and a measurement unit, and also includes a remote control unit. The robot body includes a chassis 11 , a wheel drive motor 12 , an elastic coupling 17 , a casing 13 , a battery compartment 14 , a locking rod 15 , and wheels 16 . There are four groups of wheel drive motors 12 and elastic couplings 17, which are respectively installed at four corners below the chassis 11, and each group is respectively equipped with a wheel 16. The shell 13 is installed on the top of the chassis 11 to protect the internal components, and can be removed when needed. The shell 13 is equipped with a vehicle-mounted display screen 44. The display screen of the vehicle-mounted display screen 44 is as follows: Figure 12 As shown, the status information of the wall-climbing robot can be dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com