Real-time plugging device for undersea oil-leaking pipelines

A technology for plugging devices and oil leakage pipelines, which is applied to special pipes, pipe components, pipes/pipe joints/fittings, etc., and can solve problems such as high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

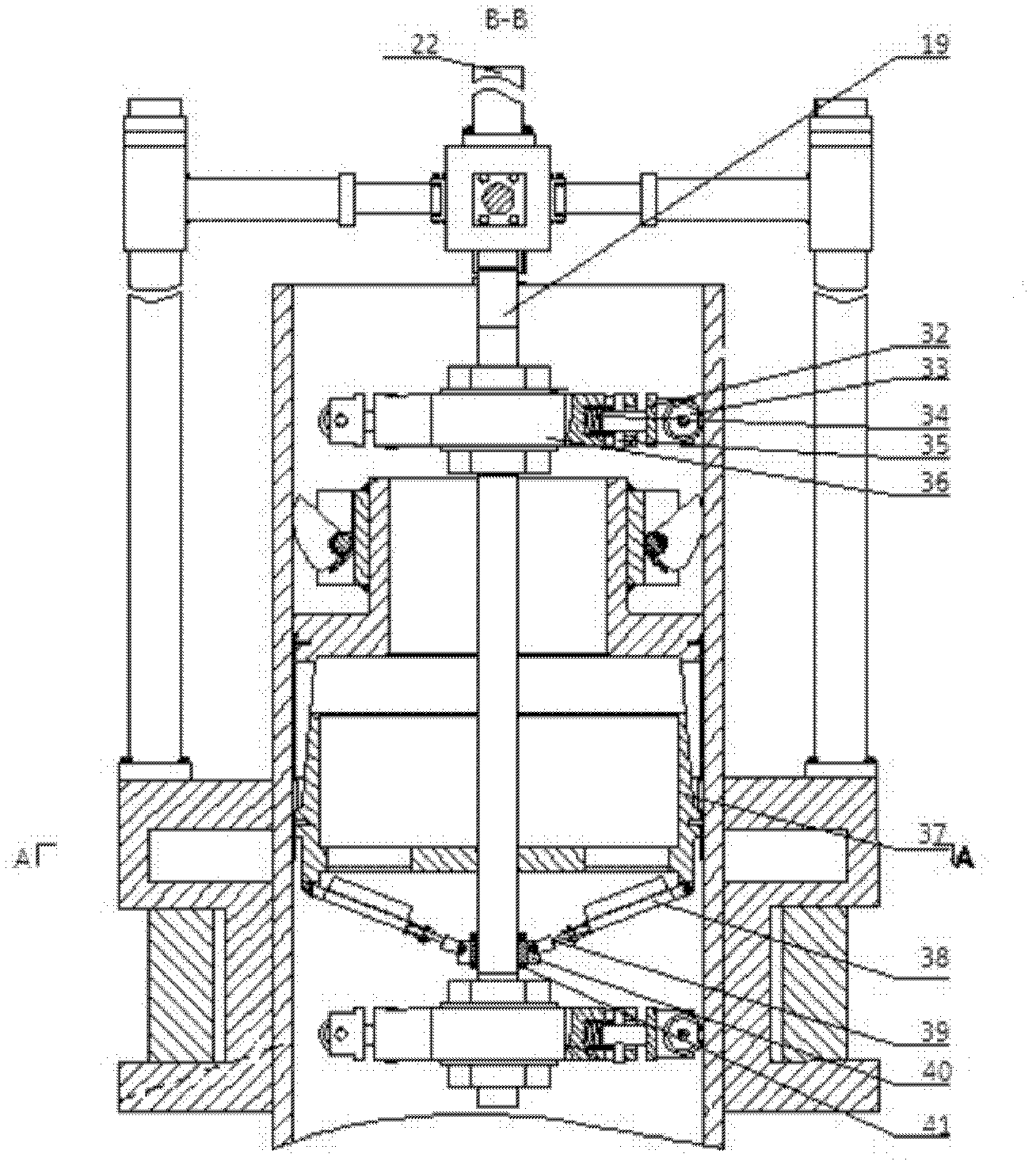

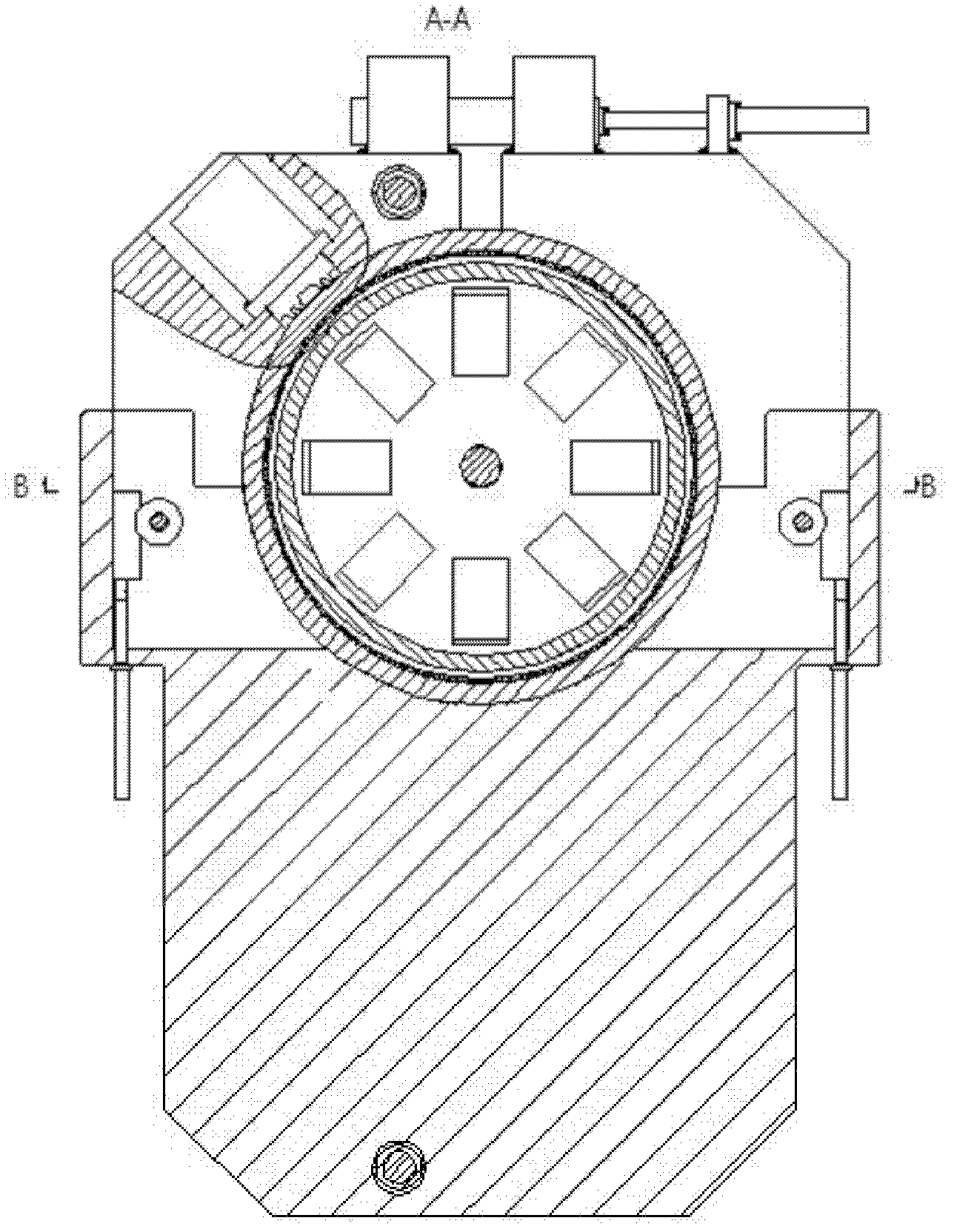

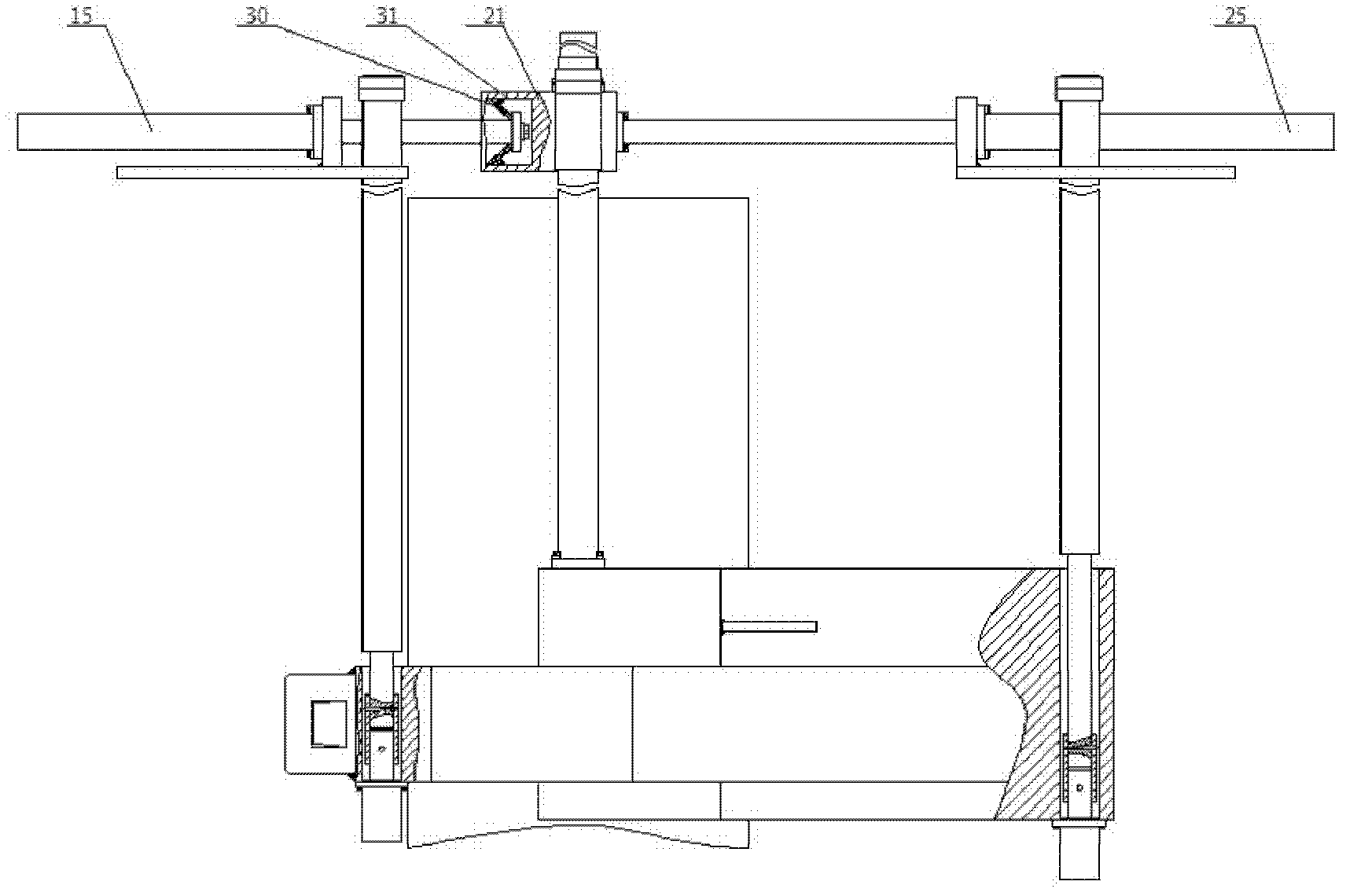

[0024] combine Figure 1~6 , the device includes a gear, a rack, a rack end hydraulic cylinder, a clamping hydraulic cylinder, a fixture base, a clamping mechanism composed of claws (1), claws (2), and a locking device; the lead screw (1) , lead screw (2), guide post, sleeve (1), sleeve (2), middle block, side hydraulic cylinder (1), side hydraulic cylinder (2), top hydraulic cylinder, etc.; , expansion sleeve, cam, torsion spring (1), center rod and other components of the expansion mechanism.

[0025] First of all, due to the hollow umbrella structure design, that is, there are eight symmetrical rectangular holes on the end face of the expansion sleeve. When working, with the movement of the central rod, the eight pull blocks open in an umbrella shape, and the oil flows from the eight The gap of the two pull blocks flows into the expansion mechanism and then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com