Oil-based microemulsion plugging agent for well drilling fluid and preparation method of plugging agent

A drilling fluid and plugging agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of blindness of plugging, contamination of reservoir sections, unfavorable plugging performance of oil-based drilling fluids, etc. Improve the plugging efficiency, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

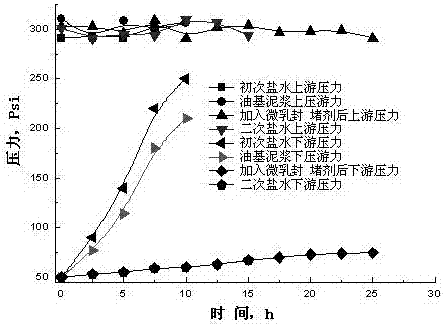

Image

Examples

Embodiment 1

[0020] First, pour 25g of water into the reaction vessel, heat up to 25°C, add 7g of isotridecanyl polyoxyethylene ether RO-(CH 2 CH 2 O)5-H; R=iso-C1 3 h 27 Add it into the reaction vessel, and then stir evenly at a speed of 2500r / min. After stirring evenly, slowly add 65g of 15# white oil dropwise, and stir at a speed of 3000r / min until the mixed liquid becomes a transparent and uniform liquid. During this process In the process, the temperature needs to be maintained at 25°C, and it is allowed to stand for 10 hours. Then add 3g of nano-calcium carbonate (particle size 80~100nm) into the above reaction vessel and stir evenly at a speed of 2500r / min. .

Embodiment 2

[0022] First, pour 30g of water into the reaction vessel, heat to 25°C, add 5g of isotridecanyl polyoxyethylene ether RO-(CH 2 CH 2 O) 7 -H; R=iso-C 13 h 27 Add it into the reaction vessel, and stir at a speed of 2500r / min. After stirring evenly, slowly add 30g of 7# white oil and 30g of 15# white oil dropwise at the same time, and stir at a speed of 3000r / min until the mixture becomes transparent Homogeneous liquid, during this process, the temperature needs to be maintained at 25°C, and it is allowed to stand for 10 hours. Then add 2g nano calcium carbonate (particle size 80~100nm), 3g nano silicon dioxide SP 50 (Particle size 50nm±5nm) Stir evenly at a speed of 2500r / min, when it presents a uniform translucent state, discharge the oil-based microemulsion plugging agent for drilling fluid.

Embodiment 3

[0024] First, pour 40g of water into the reaction vessel, heat to 30°C, add 3g of isotridecanyl polyoxyethylene ether RO-(CH 2 CH 2O ) 5 -H; R=iso-C 13 h 27 Add it into the reaction vessel, and then stir evenly at a speed of 2500r / min. After stirring evenly, slowly add 60g of silicone oil dropwise, and stir at a speed of 3000r / min until the mixed liquid becomes a transparent and uniform liquid. During this process, the temperature Need to maintain 30 ℃, let it stand for 8h. Then add 2g nano calcium carbonate (particle size 80~100nm), 2g nano silicon dioxide SP 50 (Particle size 50nm±5nm), 3g nanometer aluminum oxide γ-Al 2 o 3 (Particle size 20nm±2nm). Stir evenly at a speed of 2500r / min, and when it is uniform and translucent, discharge the oil-based microemulsion plugging agent for drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com