Inside-transformer-station daily inspection tour system based on electric power 4G data transmission, and operating method of the same

A data transmission and substation technology, applied in transmission systems, information technology support systems, electrical components, etc., can solve the problem that the quality of work depends on the professionalism and sense of responsibility of the staff, and the inspection work of substations cannot get rid of carrying a lot of paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

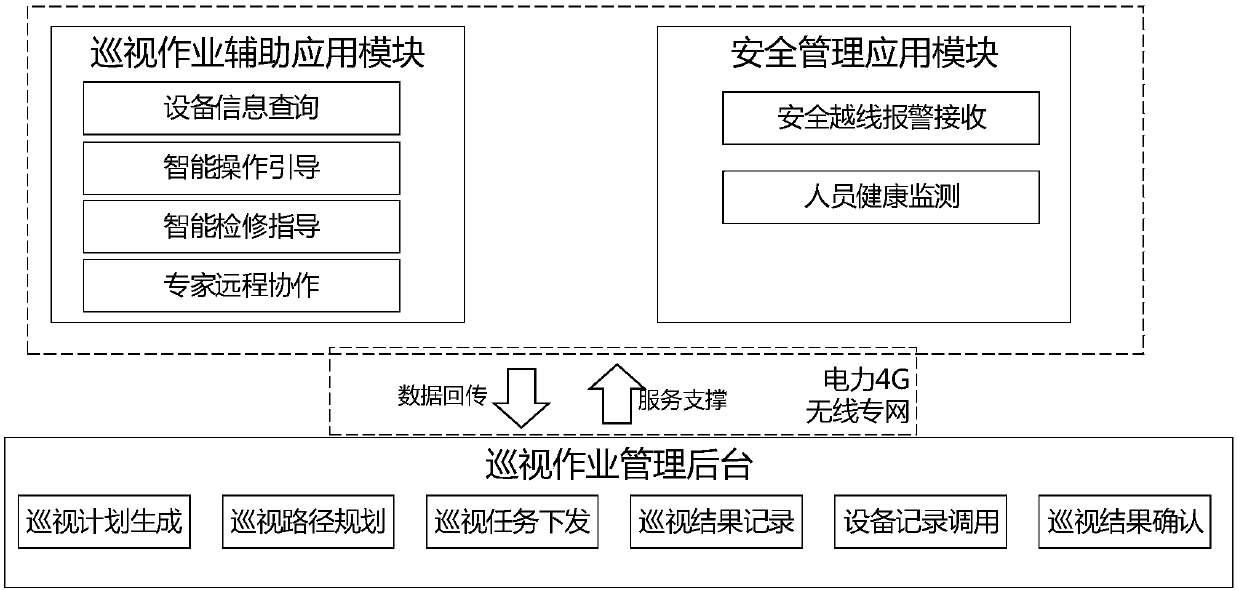

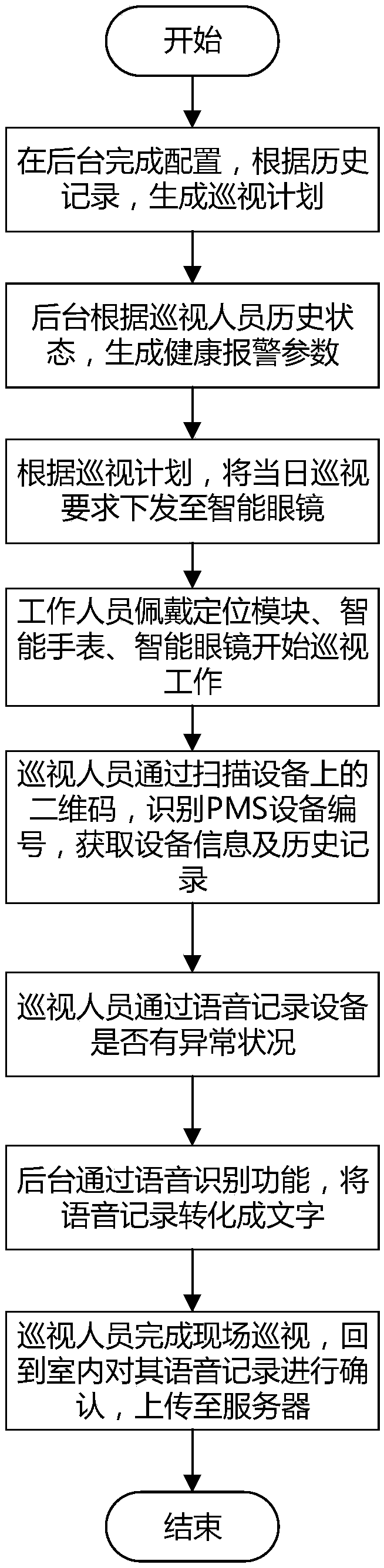

[0028] The present invention integrates and uses various new information technologies through the analysis of the on-site operation requirements of the production business. On this basis, it conducts substation inspection operations, formulates inspection procedures, and simultaneously innovates its safety management methods. The specific implementation process consists of the following steps:

[0029] 1. Deploy substation hardware support environment:

[0030] 1) Deploy the positioning service base station: select the appropriate positioning method according to the type of substation. Select suitable positioning products for indoor stations and outdoor stations respectively. For safety reasons, the positioning accuracy is required to be centimeter level.

[0031] 2) Deploy the local area network environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com