Swivel arrangement for carousel filler

A technology of rotary device and filler, which is applied in packaging, liquid bottling, transportation and packaging, etc., and can solve problems such as the speed limitation of rotary tank and rotary transfer filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

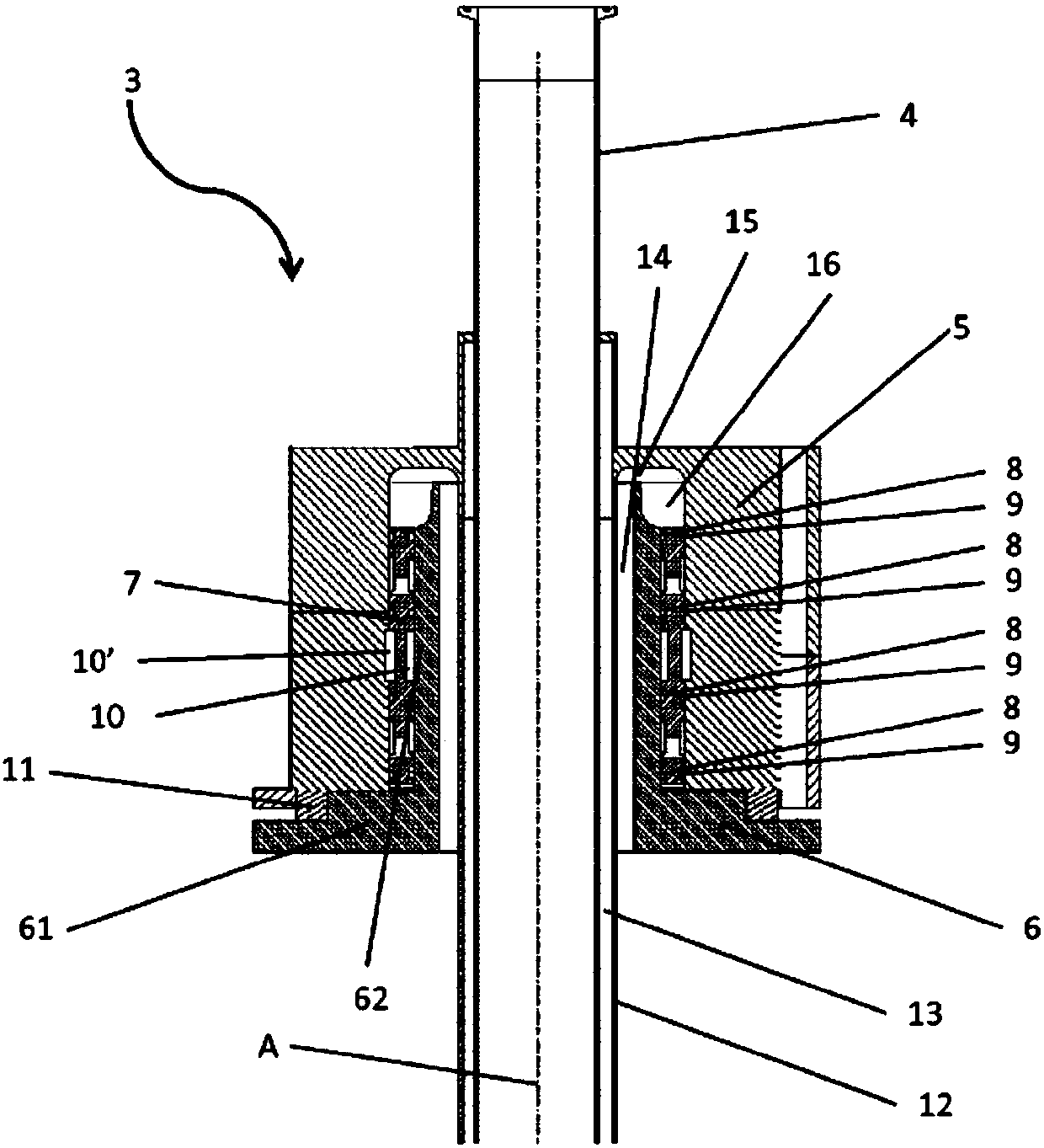

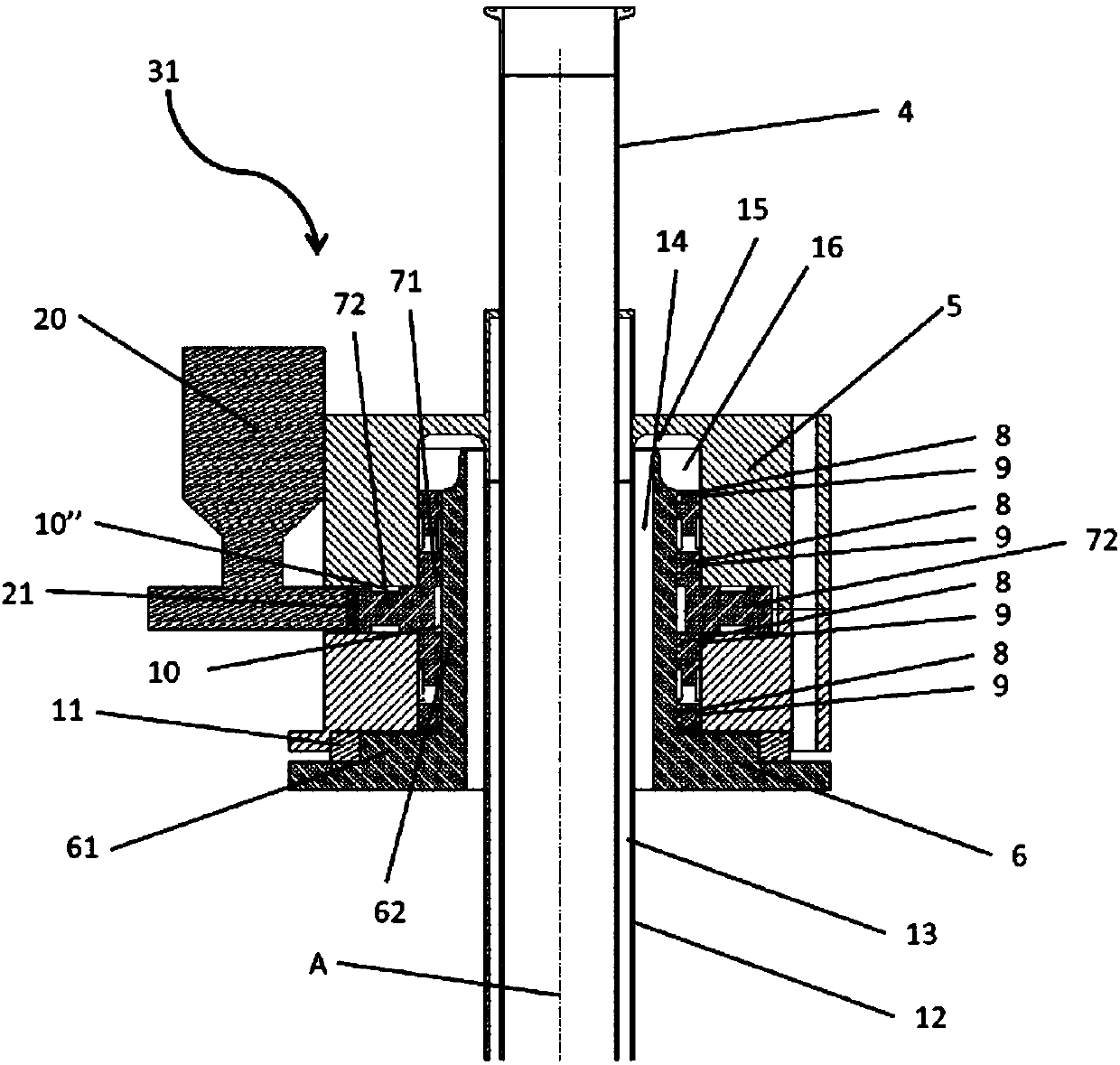

[0027] In this detailed description, embodiments of rotary transfer fillers and rotary devices according to the present invention are mainly discussed with reference to schematic cross-sectional views showing rotary devices according to various embodiments of the invention. It should be noted that this is not meant to limit the scope of the invention, which also applies to other situations, such as other types or variants of rotary transfer fillers compared to the embodiment shown in the drawings or device. Furthermore, the mention of particular components in connection with one embodiment of the invention does not imply that those components cannot be used with other embodiments of the invention. The invention will now be described with reference to the drawings, wherein attention will be given first to structure and second to function.

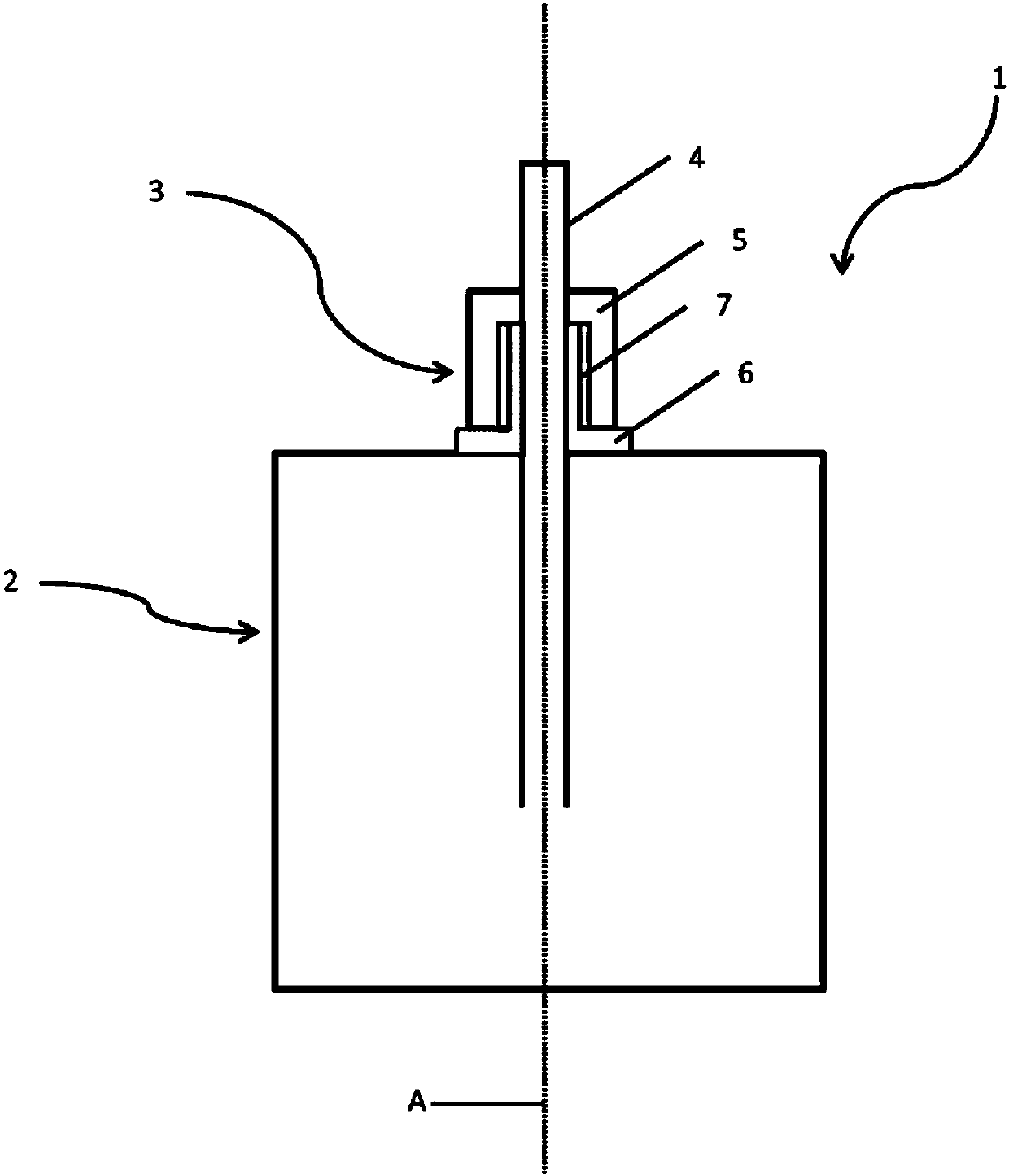

[0028] figure 1 A schematic cross-sectional view of a carousel filler 1 according to an embodiment of the invention is shown. The rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com