Liquid crystal display element

A technology for liquid crystal display elements and liquid crystal compositions, applied in the directions of liquid crystal materials, instruments, optics, etc., can solve the problems of prolonged time, no effective method found, liquid crystal decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

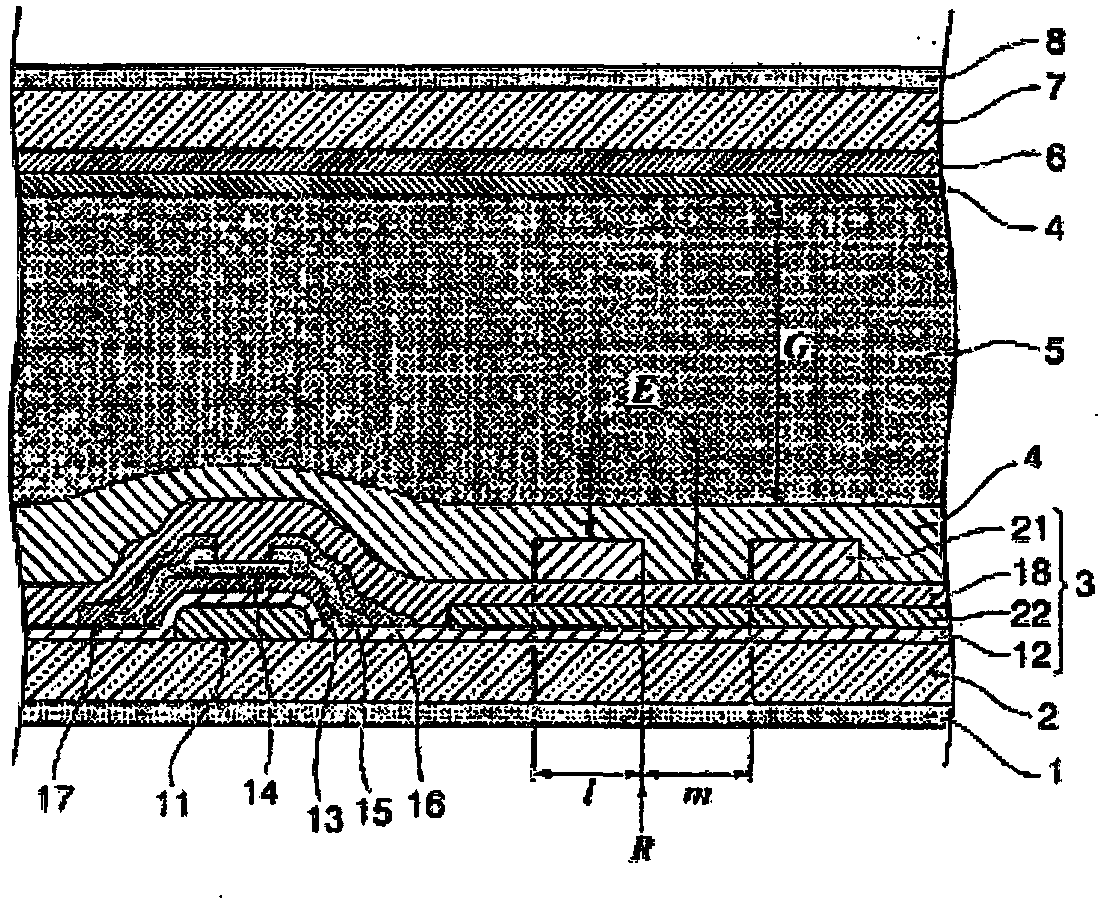

[0627] 97% of the N-type liquid crystal composition (LCN-1), 2.94% of the polymerizable compound (V1), and 0.06% of the photopolymerization initiator No. 1 described in Table 10 below (as the ratio of these polymerizable compounds and the photopolymerization initiator The polymeric composition 3%) of the mixture was mixed to prepare composition 1.

[0628] After forming a polyimide alignment film with a cell gap of 3 μm on a glass substrate so that the homeotropic alignment of the liquid crystal can be obtained, it is carried out so that the pretilt angle becomes 1° to 2° with respect to the normal direction of the substrate. Rubbing Orientation Treatment, making rubbed oriented cells with ITO.

[0629] Composition 1 was heated to 60° C. to dissolve the solid polymerizable compound (V1). Regarding composition 1, it was confirmed by a polarizing microscope that the polymerizable compound (V1) was uniformly dissolved at room temperature and that a nematic liquid crystal phase a...

Embodiment 2~23、 comparative example 1~3

[0640] Except having adjusted the liquid crystal composition, polymeric compound, and initiator as shown in following Table 1, it carried out similarly to Example 1, and produced the liquid crystal display element of VA mode.

[0641] Using a polarizing microscope, when the produced unit is placed between two orthogonal polarizers, it becomes a dark field. Even if the unit is rotated in the azimuth direction, the blackness of the dark field does not change, so it is confirmed that the polymer is vertically oriented and The direction of the optical axis of the network is the same as the direction of the easy-orientation axis of the liquid crystal composition.

[0642] The composition for producing the unit was left at 20° C. for one week, and no crystallization by the polymerizable compound was confirmed. Response time was measured by applying a 60 Hz rectangular wave to the obtained VA mode liquid crystal display element. The results are shown in Table 1. In Comparativ...

Embodiment 24~25、 comparative example 4~5

[0647] Except having adjusted the liquid crystal composition, polymerizable compound, and photoinitiator as shown in following Table 2, it carried out similarly to Example 1, and produced the liquid crystal display element of VA mode.

[0648] Using a polarizing microscope, when the produced unit is placed between two orthogonal polarizers, it becomes a dark field. Even if the unit is rotated in the azimuth direction, the blackness of the dark field does not change, so it is confirmed that the polymer is vertically oriented and The direction of the optical axis of the network is the same as the direction of the easy-orientation axis of the liquid crystal composition.

[0649] The composition for producing the unit was left at 20° C. for one week, and no crystallization by the polymerizable compound was confirmed. Response time was measured by applying a 60 Hz rectangular wave to the obtained VA mode liquid crystal display element. The results are shown in 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com