LCD device

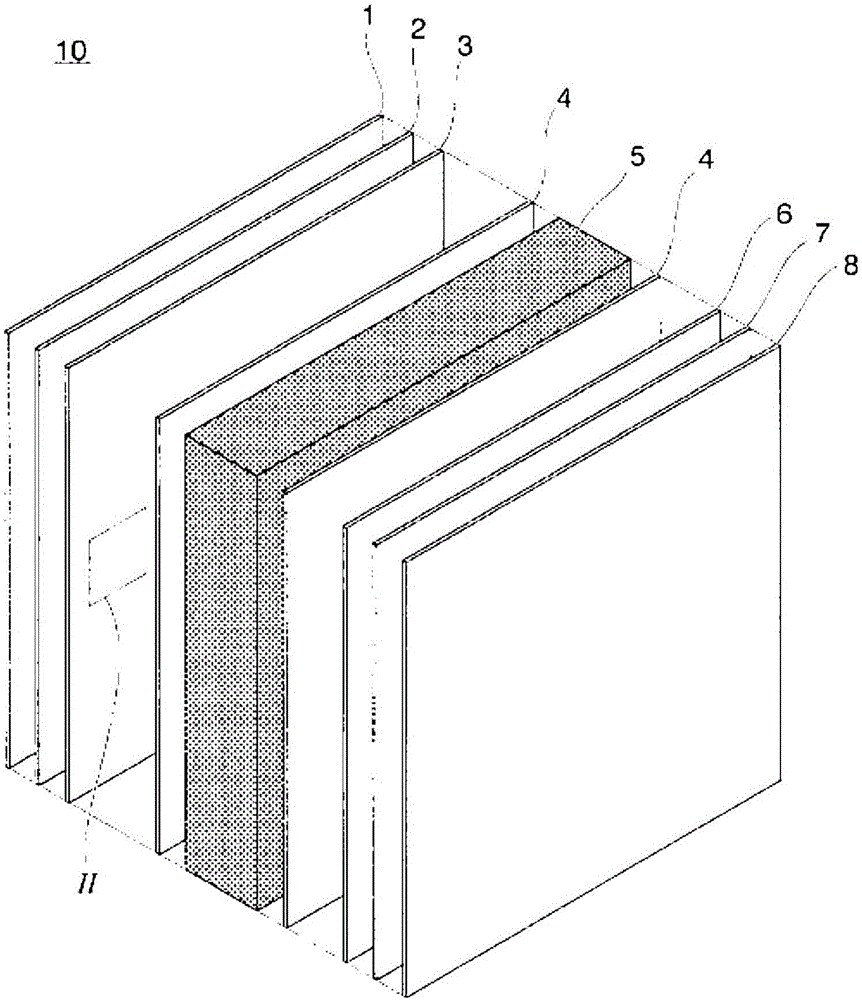

A technology of liquid crystal display element and liquid crystal composition, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., and can solve the problems of no effective method found, low viscosity, etc.

- Summary

- Abstract

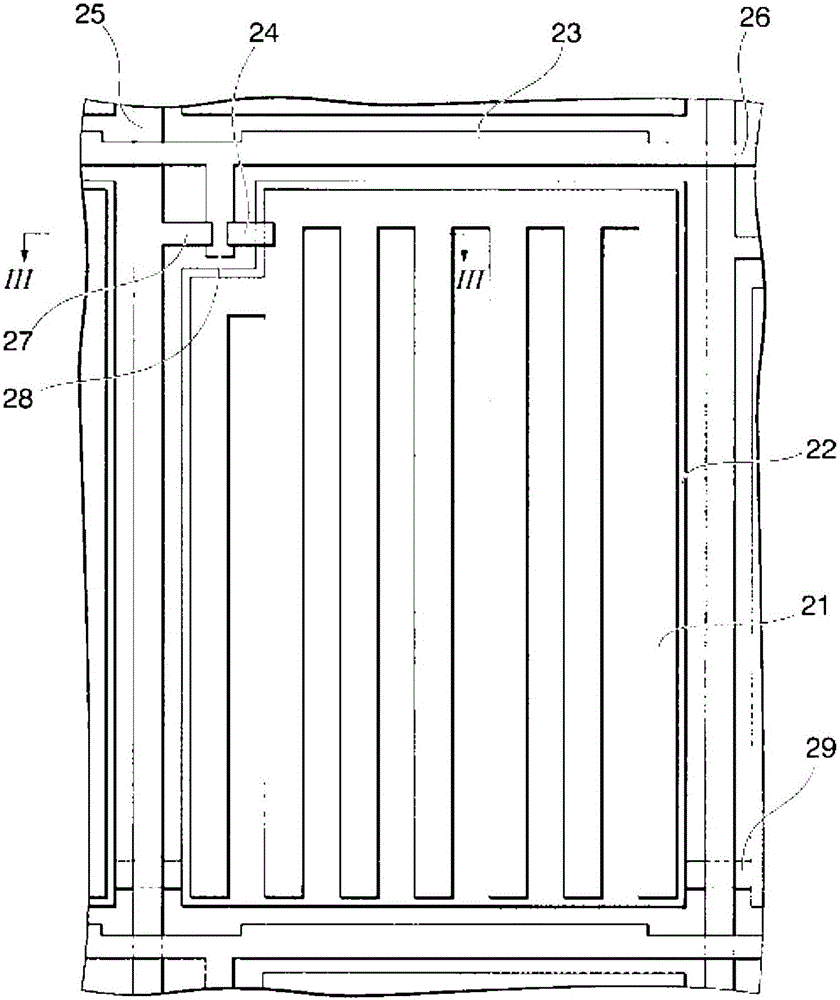

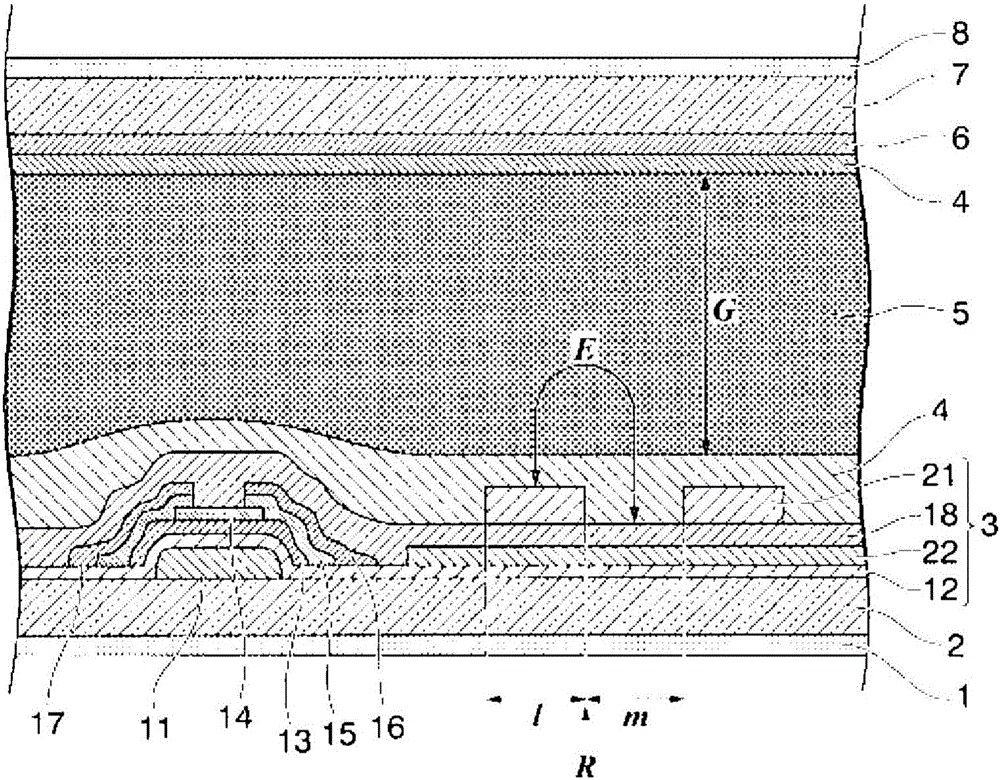

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0665] A composition (Δn: 0.103, viscosity η: 20 mPa·s, Vth: 1.72 Vrms) represented by the following (LCP-1) was prepared as a P-type liquid crystal composition. A compound represented by the following formula (V1-1-1) was used as a polymerizable compound.

[0666]Preparation of P-type liquid crystal composition (LCP-1) 100-97%, polymerizable compound (V1-1-1) 1.96-2.94%, polymerization photoinitiator Irgacure651 relative to polymerizable compound (V1-1-1) 2 % of polymerizable liquid crystal composition (LCM-1). After heating the solid polymerizable compound (V1-1-1) to 60°C to dissolve it in the liquid crystal (LCP-1), it was confirmed with a polarizing microscope that the polymerizable compound (V1-1-1) was homogeneous at room temperature. Dissolved to present a nematic liquid crystal phase.

[0667] In order to obtain uniaxial alignment (horizontal alignment) of liquid crystals, a polyimide alignment film-coated cell with parallel rubbing alignment of ITO with a cell gap ...

Embodiment 2

[0679] Prepare a P-type liquid crystal composition (LCP-1; Δn: 0.103, viscosity η: 20mPa·s) 95%, polymeric compound (V1-1-1) 5% and relative to the polymeric compound (V1-1-1 ) is a polymerizable liquid crystal composition (LCM-1) of 2% polymerizable photoinitiator Irgacure651.

[0680] In order to obtain uniaxial alignment (horizontal alignment) of liquid crystals, a cell with a cell gap of 3.5 μm coated with a polyimide alignment film and with parallel rubbed alignment of ITO was used. The polymerizable liquid crystal composition (LCM-1) was heated to 60° C. to be dissolved in LCP-1, and injected into the glass cell by a vacuum injection method.

[0681] After the injection, the glass cell was taken out, and the injection port was sealed with a sealant 3026E (manufactured by Three Bond). The irradiation intensity after passing through the ultraviolet cut filter L-37 (manufactured by HOYA CANDEO OPTRONICS) at 25°C or -10°C is 15mW / cm 2 UV rays for 300 seconds. There...

Embodiment 3

[0685] A composition (Δn: 0.102, viscosity η: 16.8, Δε: -3.8) represented by the following (LCN-1) was prepared as an N-type liquid crystal composition. A compound represented by formula (V1-1-2) is used as a polymerizable compound.

[0686] Prepared N-type liquid crystal composition (LCN-1; Δn: 0.102, viscosity η: 16.8, Δε: -3.8) 96%, polymeric compound (V1-1-2) 4% and relative to polymeric compound (V1- 1-2) A polymerizable liquid crystal composition (LCM-2) containing 2% of a polymerizable photoinitiator Irgacure651.

[0687] In order to obtain the homeotropic alignment of the liquid crystal, use a cell gap of 3 μm, apply a polyimide alignment film, and perform a rubbing alignment treatment to form a pretilt angle of 1° to 2° with respect to the normal direction of the substrate surface. of parallel rubbed-oriented cells. After heating the solid polymerizable compound (V1-1-2) to 60°C to dissolve it in the liquid crystal (LCN-1), it was confirmed by a polarizing mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com