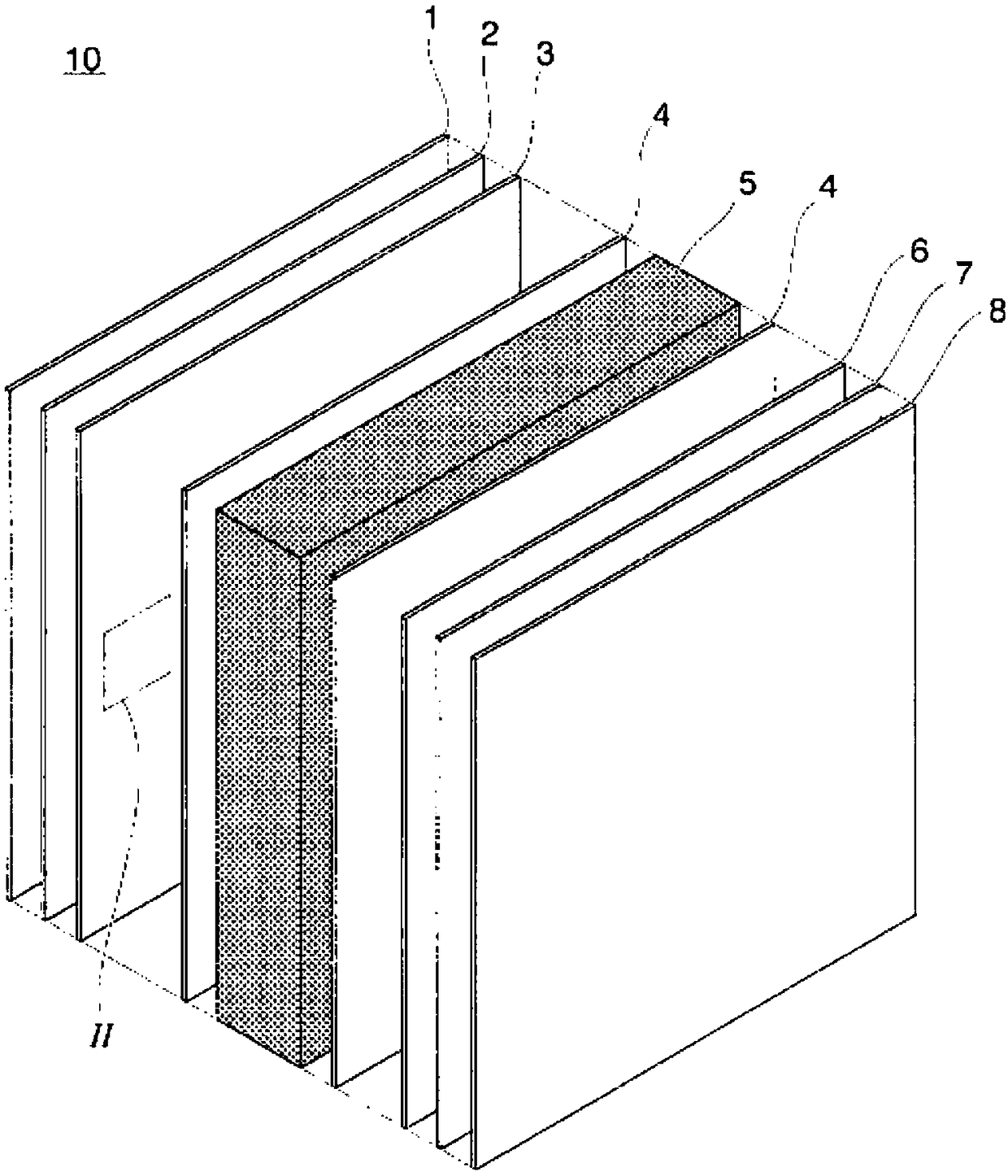

Liquid crystal display element and method for manufacturing same

A technology of liquid crystal display element and manufacturing method, which is applied in the directions of liquid crystal materials, chemical instruments and methods, optics, etc., and can solve the problems such as no effective method yet found, low viscosity of liquid crystal composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0523] A composition (Δn 0.103, viscosity η 16.5, Δε-3.1) shown in the following (LCN-1) was prepared as an N-type liquid crystal composition. The N-type liquid crystal composition (LCN-1) was heated to 60° C., and the solid polymerizable compound (V1-1-1) and the polymerizable compound (V1-1-2) were mixed and dissolved. The polymerizable compounds (V1-1-1) and (V1-1-2) were uniformly dissolved at room temperature, and it was confirmed with a polarizing microscope that a nematic liquid crystal phase was exhibited. Irgacure 651, a polymerization photoinitiator, was mixed with this solution to prepare a polymerizable liquid crystal composition. Table 1 shows the composition table of the prepared polymerizable liquid crystal composition.

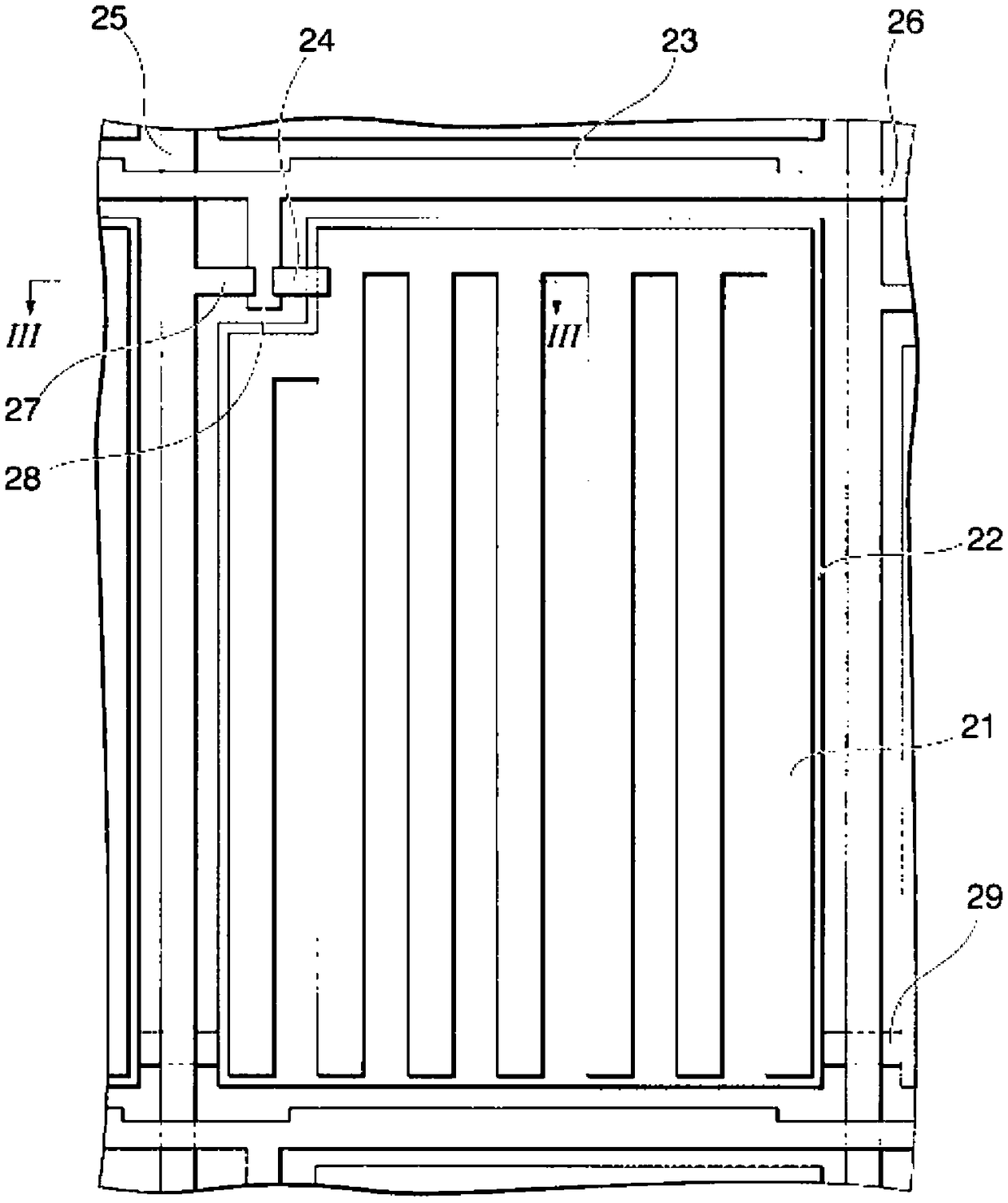

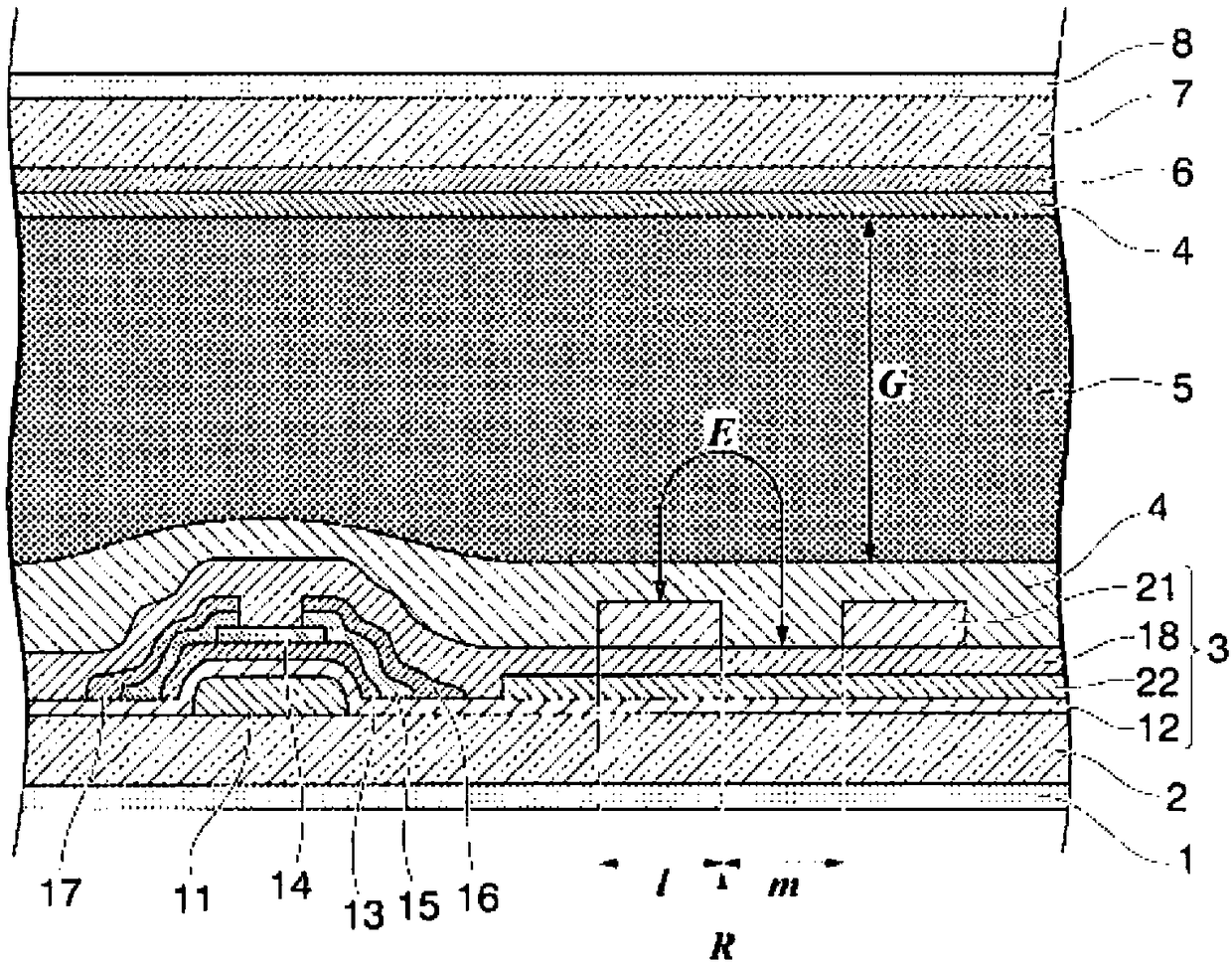

[0524] In such a way that uniaxial alignment (horizontal alignment) of liquid crystals can be obtained, a herringbone pattern electrode vertical alignment (PVA) cell coated with a polyimide vertical alignment film with a cell gap of 3.6 μm...

Embodiment 2~5

[0541] In the same manner as in Example 1, the compositions of Examples 2 to 5 in Table 1 were injected into the cell.

[0542] After the injection, the glass cell was taken out, and the injection port was sealed with a sealant 3026E (manufactured by Threebond). Using an ultraviolet LED light source with a wavelength of 365nm, the irradiation intensity is 15mW / cm at 25°C 2 UV light for 80 seconds. Use a square wave with a frequency of 1kHz and 2.39V to 7.5V as the voltage, and adjust the time appropriately from the time when the ultraviolet ray is irradiated, and apply it for 5 seconds to 15 seconds. Oriented vertically, a herringbone type PVA unit is produced. This makes it possible to form a polymer network of parallel orientation components and a polymer network of vertical orientation components.

[0543] After the ultraviolet irradiation was completed, the slit direction was arranged to be inclined at 45 degrees with respect to any of the crossed Nicol polarizer...

Embodiment 6

[0546] In the same manner as in Example 1, the composition of Example 6 in Table 1 was injected into the cell.

[0547] After the injection, the glass cell was taken out, and the injection port was sealed with a sealant 3026E (manufactured by Threebond). Using an ultraviolet LED light source with a wavelength of 365nm, the irradiation intensity is 15mW / cm at 25°C 2 UV light for 80 seconds. A rectangular wave with a frequency of 1 kHz and 2.45 V was used as a voltage, and after 12 seconds from the start of ultraviolet irradiation, the voltage was set to 0 V in the state of ultraviolet irradiation, and the vertical orientation was returned to produce a herringbone PVA unit. This makes it possible to form a polymer network of parallel orientation components and a polymer network of vertical orientation components.

[0548] After the ultraviolet irradiation was completed, the slit direction was arranged to be inclined at 45 degrees with respect to any of the crossed Nicol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com