Electric injecting device of injection molding machine

A technology of injection device and injection molding machine, which is applied in the field of injection device, can solve the problems of precision improvement, troublesome installation and maintenance, etc., and achieve the effects of improved plasticizing precision, convenient installation and maintenance, and high transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

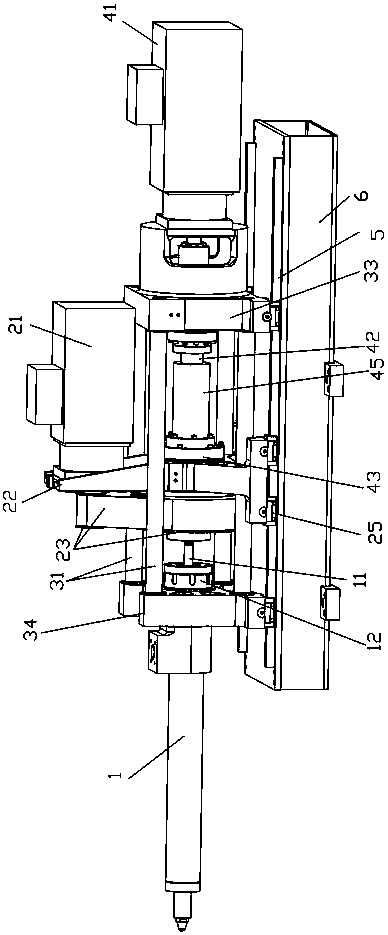

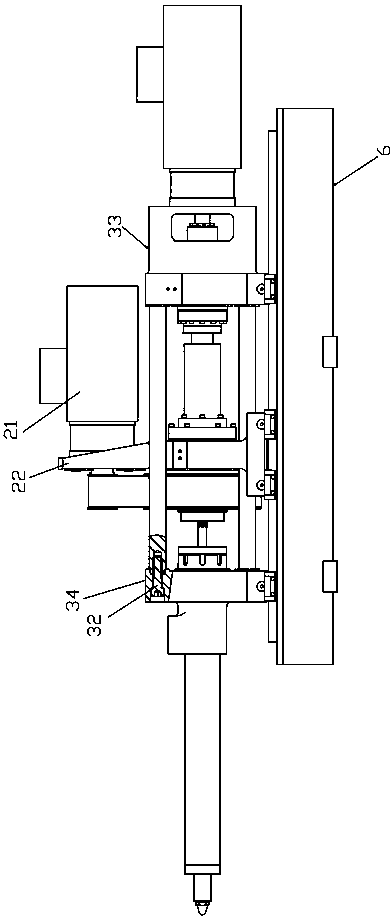

[0021] Such as figure 1 , 2 As shown, the electric injection device of the injection molding machine includes a barrel assembly 1, an injection base assembly, a pre-plasticizing mechanism, and an injection mechanism.

[0022] Such as image 3 , 4 As shown, the above-mentioned shooting base assembly includes a shooting front plate 34, a shooting back plate 33, a shooting rod 31 and a bolt 32. The shooting front plate 34 and the shooting back plate 33 are connected by the shooting rod 31 and the nut 32 respectively. Together, the two bottoms of the front plate 34 of the shooting table are respectively provided with front slides of the shooting table, each of the front slides of the shooting table is placed on the linear guide 5 respectively, and the bottom of the two sides of the shooting table rear plate is also provided with the shooting table rear plate. The sliders, each of the rear plate sliders of the shooting platform are respectively placed on the linear guide 5.

[0023] The...

Embodiment 2

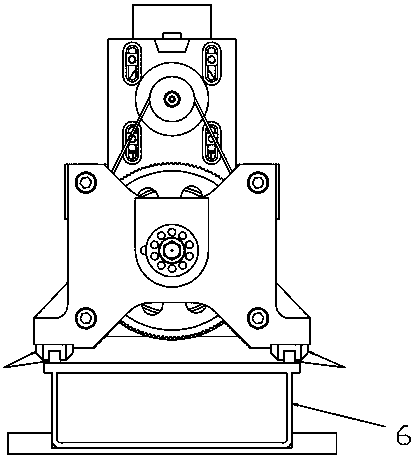

[0030] The injection motor 41 in the first embodiment is fixed on the inner side of the pre-plastic seat 22.

[0031] The transmission mechanism of this embodiment includes synchronous wheels 48, 49, a synchronous belt 47 and an injection screw nut. One synchronous wheel 49 is fixed on the motor shaft of the injection motor 41, the other synchronous wheel 48 is fixed on the injection screw, and two The synchronous wheels 48 and 49 are connected by a synchronous belt 47.

[0032] The rest of the structure is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com