Installing and positioning mechanism and method for large embedded part anchor rod structure

A technology for installation and positioning and bolting, which is applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of inconvenient docking of bolt holes and difficult relative positions, and achieve the effect of saving installation and positioning time and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

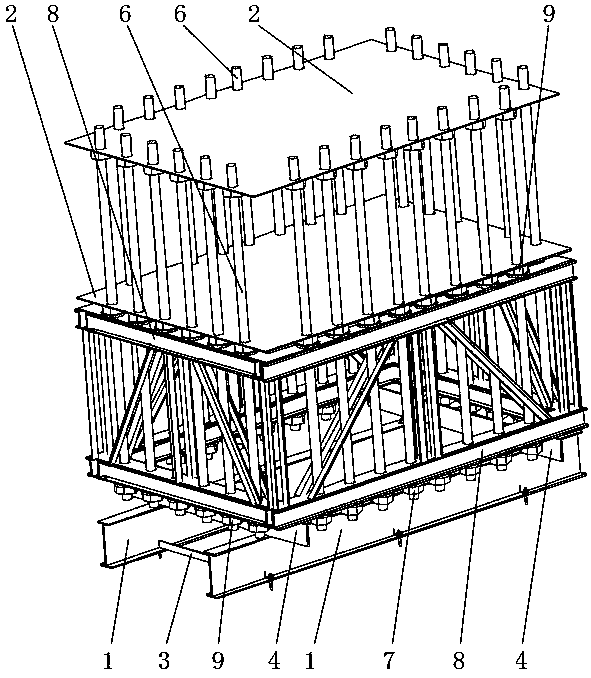

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

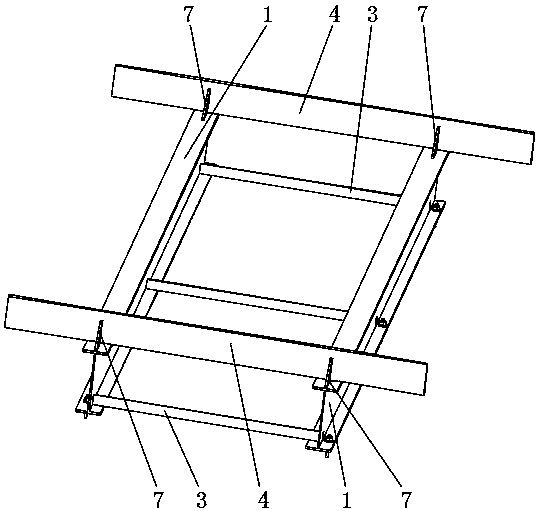

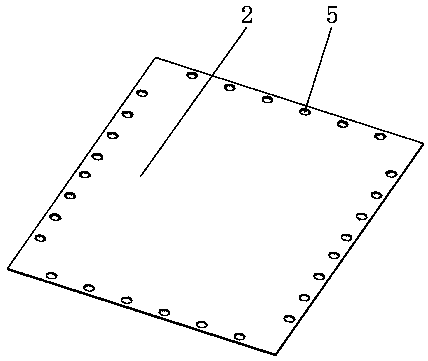

[0023] like Figures 1 to 3 As shown, an installation and positioning mechanism for a large-scale embedded anchor structure includes two support seats 1 parallel to each other at the bottom of the embedded anchor structure and a positioning plate 2 on the top. The support seat 1 is specifically H-shaped steel, and the height of the H-shaped steel is 400mm, the two supporting bases 1 are fixedly connected to the foundation, the lower flange plates of the two H-shaped steels are fixedly connected to the foundation through expansion bolts, and the two supporting bases 1 are fixedly connected by a reinforcement 3, which is specifically an angle steel. The two ends of the member 3 are respectively in contact with and fixedly connected to the lower parts of the inner sides of the two support seats 1, and the bottom of the reinforcement member 3 is in contact with and fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com