Conducting ring locating technology of high-power and low-voltage motor

A conductive ring, low-voltage technology is applied in the field of positioning and installation technology of the conductive ring, which can solve the problems of waste of raw materials, increased manufacturing cost of the motor, inaccurate positioning of the conductive ring and the busbar, etc., to achieve accurate spacing, improve production efficiency, The effect of saving installation and positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

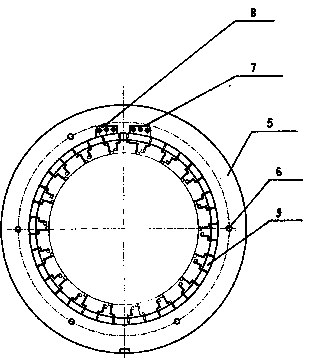

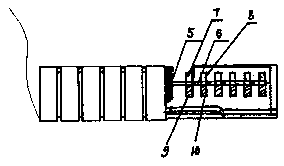

[0019] A conductive ring positioning process for a high-power low-voltage motor, comprising the following steps:

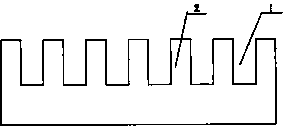

[0020] The first step is to process the conductive ring positioning slots 1 at equal intervals on the rectangular conductive ring positioning card. The number of conductive ring positioning slots 1 is equal to the number of conductive rings of high-power and low-voltage motors, and the adjacent The spacing 2 between the positioning grooves 1 of the two conductive rings is the positioning spacing;

[0021] The second step is to process the positioning arc surface 11 at the bottom of the rectangular bus bar positioning plate, so that the radian of the positioning arc surface 11 is the same as the outer arc surface of the conductive ring of the high-power low-voltage motor, and process it on the bus bar positioning plate Exit the bus bar positioning hole 4 and another bus bar positioning hole 12, so that the spacing between the two bus bar positioning holes is equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com