A pneumatic universal butt joint air supply device

A pneumatic and universal technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of large cooling of molten steel, difficult operation, delay in blowing operation time, etc., and achieve the receiving capacity Strong, ensuring reliability and sealing, and ensuring the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, without limiting the scope of protection.

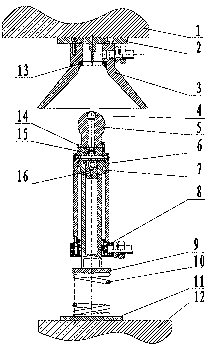

[0018] A pneumatic universal butt joint air supply device is characterized in that the device includes: an air connection mechanism and an air supply mechanism, and the structural diagram of the air supply device is as follows figure 1 shown.

[0019] Such as figure 1 As shown, the gas-connecting mechanism includes: a gas-connecting mechanism base (2), a built-in soft seal (13), and a guide cone (3). Such as figure 1 As shown, the base of the air connection mechanism (2) has a sealing groove on the side in contact with the guide cone (3), and the sealing ring is installed in this sealing groove. The base of the gas connection mechanism (2) and the guide cone (3) Connect with screws between them, the high-pressure hose is installed on the air outlet position of the guide cone (3), and the whole gas co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com