High-precision pen-type injector

A pen-type injector, high-precision technology, applied in the direction of syringes, ampoule syringes, hypodermic injection devices, etc., can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

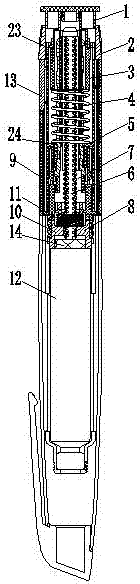

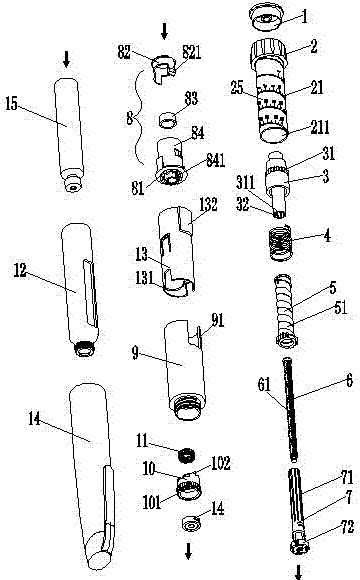

[0018] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

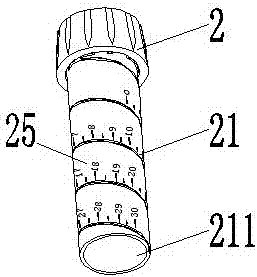

[0019] see Figure 1-6 As shown, a high-precision pen injector includes an injection button 1, a dose adjustment knob 2, a clutch ratchet 3, a clutch spring 4, a spiral sleeve 5, a screw rod 6, a spiral ratchet 7, a fixed ratchet assembly 8, and a main body Shell 9, reset knob 10, return spring 11, drug silo 12 and dose display sleeve 13, said dose display sleeve 13 is fixed in the hole of main body upper shell 9, and the inner hole of dose display sleeve 13 has a second A helical groove 131 , the dose adjustment knob 2 is provided with a second helical groove 21 , and the first helical groove 131 cooperates with the second helical groove 21 . When the dose adjustment knob 2 is rotated, the dose adjustment knob 2 can be rotated up through two helical grooves, and the inner wall of the first inner hole 211 of the dose adjustment knob 2 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com