Flow guiding device, refueling component and refueling method

A diversion device and component technology, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve problems such as business interruption, failure of terminal UPS system to operate normally, and unstable output voltage of generator sets. Achieve the effects of slowing down the liquid flow rate, compact structure, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

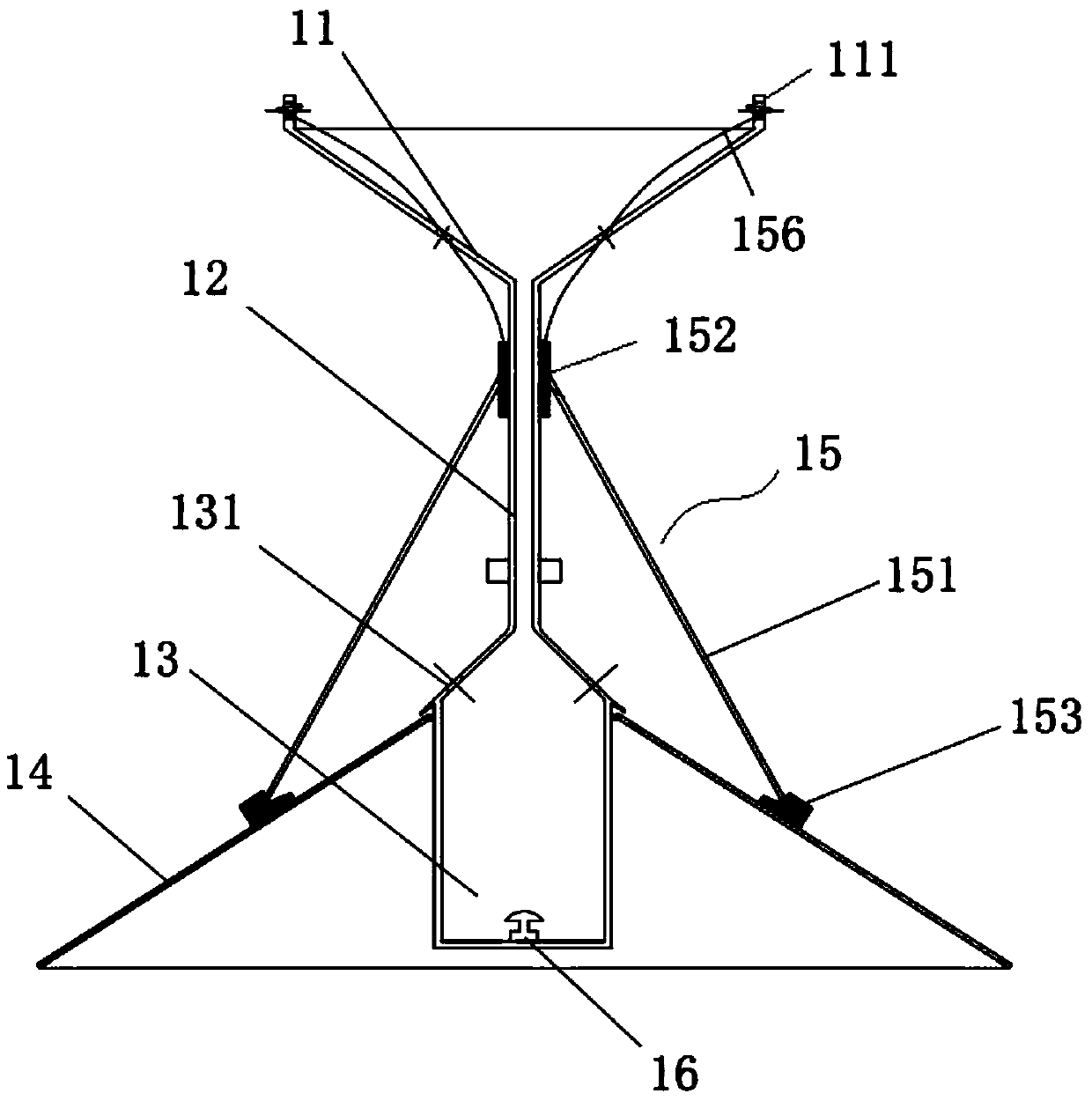

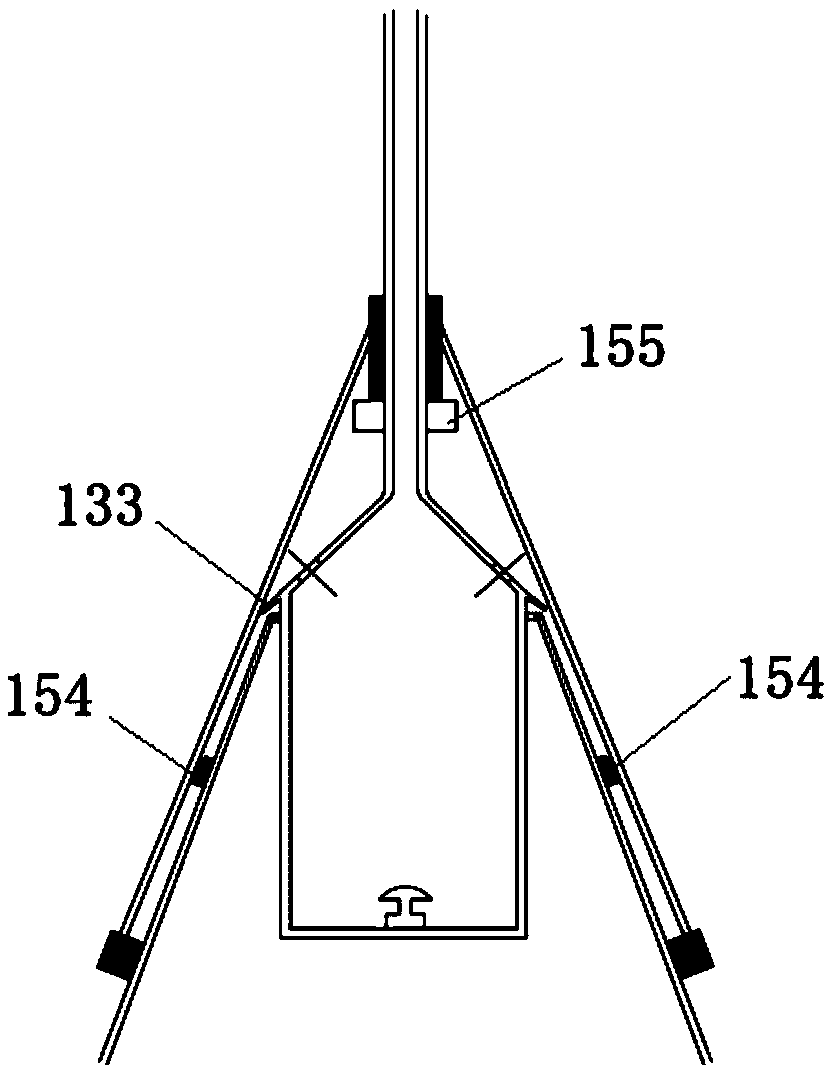

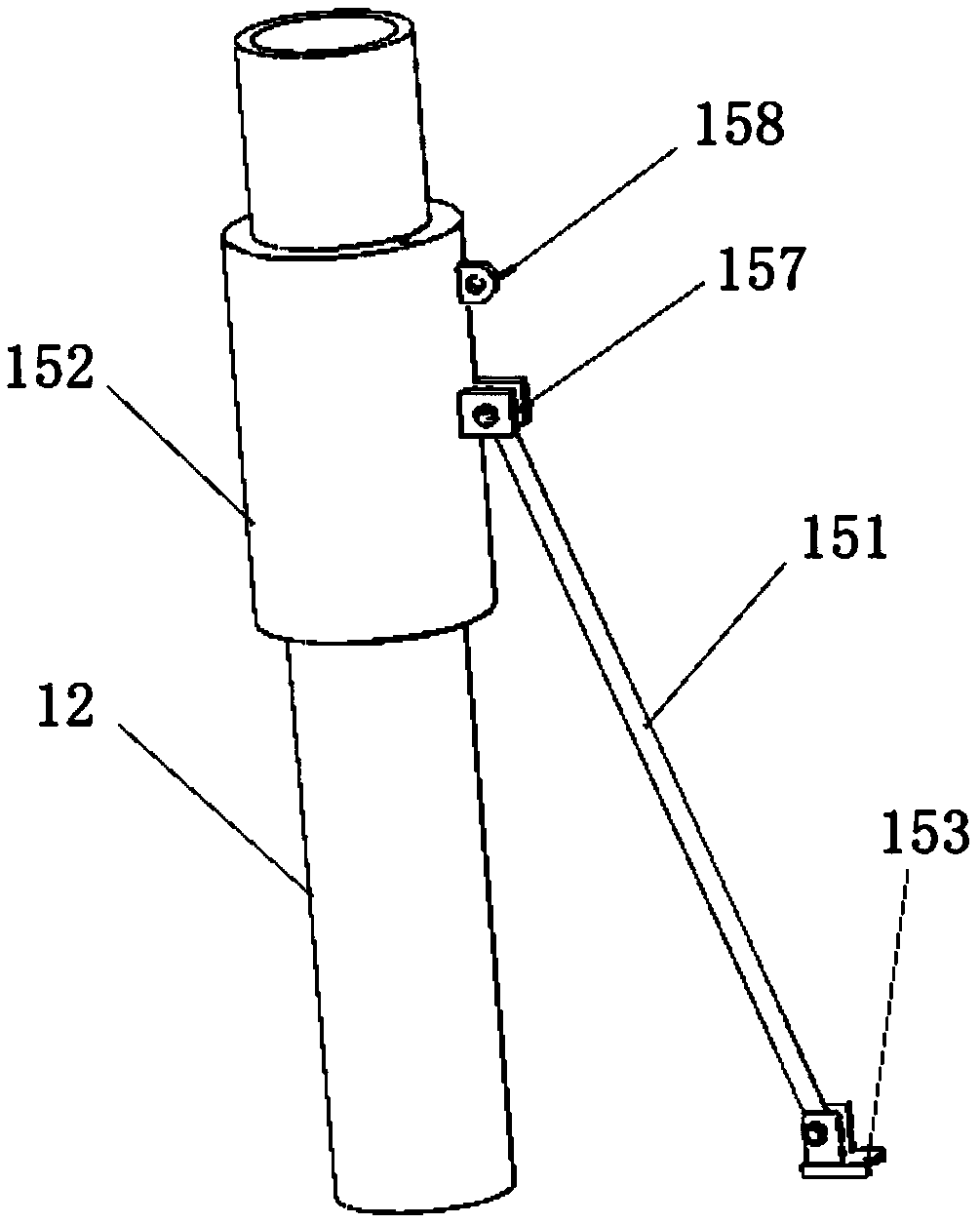

[0053] figure 1 It is a flow guiding device provided by the embodiment of the present invention, which can be used to guide the liquid when pouring liquid into the container, including: a partial pressure container 13, a flow guide tube 12, a flow divider 14 and a control mechanism 15, in,

[0054] The partial pressure container 13 is used for buffering the liquid, and a diversion hole 131 is opened on it;

[0055] The guide tube 12 communicates with the pressure dividing container 13, and is used to guide the liquid into the pressure dividing container 13;

[0056] The flow divider 14 is connected to the outer wall of the pressure dividing container 13, and the flow divider 14 has a distributing surface 142 that can be expanded or folded, and the flow dividing surface 142 is used to guide the liquid overflowing from the diversion hole 131 of the pressure dividing vessel to flow out smoothly ;

[0057] The control mechanism 15 is used to control the expansion or contraction...

Embodiment 2

[0074] Figure 7 It is a structural schematic diagram of a refueling assembly provided by an embodiment of the present invention. see Figure 7 , a refueling assembly with a flow guide device, including a refueling pump 27, a controller 28, a fuel delivery pipe 29 and a flow guide device. Wherein, the oil delivery pipe 29 is connected with the output port of the refueling pump 27, and is used for delivering the fuel pressurized by the refueling pump 27 to the diversion device; the controller 28 is used for automatically adjusting the fuel pump 27 according to the liquid level information sent by the diversion device Oil intake.

[0075] Specifically, the flow guiding device includes a pressure dividing container 23 , a flow guiding tube 22 , a flow divider 24 , a control mechanism 25 and a liquid level detector 26 . The guide pipe 22 communicates with the pressure-dividing container, and is used to guide the fuel into the pressure-dividing container 23 . The pressure-divid...

Embodiment 3

[0092] Figure 10 It is a flow chart of a refueling method provided by an embodiment of the present invention. The refueling method is completed using the refueling assembly in Embodiment 2, including:

[0093] S101. Install the flow guide device at the opening of the oil storage container, and expand the flow diversion surface of the flow divider.

[0094] S102. Move the oil delivery pipe until the outlet of the oil delivery pipe is opposite to the inlet of the draft pipe.

[0095] S103. Start the refueling pump, use the refueling pump to pressurize the fuel, the pressurized fuel enters the pressure dividing container through the fuel delivery pipe and the diversion pipe, overflows from the diversion hole on the pressure dividing container, and smoothly flows into the storage tank along the diversion surface of the diverter oil container.

[0096] As an optional method, installing the flow guiding device at the opening of the oil storage container, and expanding the flow di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com