Dust removal type urban fallen leaf collection and fermentation system

A fermentation system and fallen leaves technology, which is applied in the field of dust-removing urban fallen leaves collection and fermentation system, can solve the problems of easily polluted environment, unfavorable smog control, etc., and achieve the effect of avoiding dense smoke pollution, avoiding the increase of smog and reducing the amount of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] As shown in the figure, the specific implementation method is as follows:

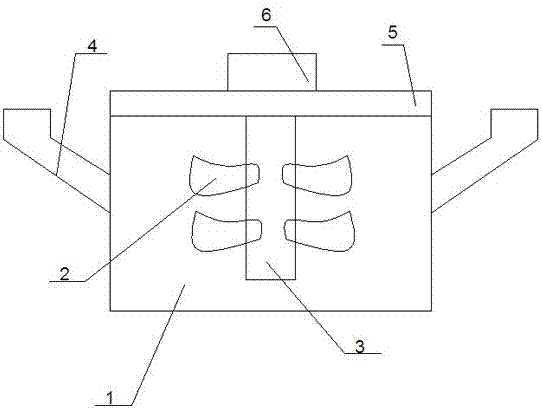

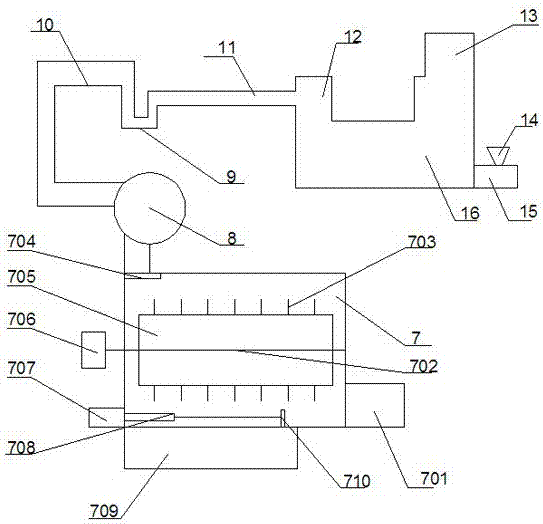

[0014] A dust-removing urban fallen leaf collection and fermentation system, comprising a fallen leaf collection and crushing device and a fallen leaf fermentation tank, the fallen leaf fermentation tank includes a tank body 1 and a tank cover 5 that is arranged on the entrance of the tank body 1, and the outer side wall of the tank body 1 There is a feeding pipe 4 for adding enzymes and water, the distance between the connection between the feeding pipe 4 and the inner cavity of the tank body 4 and the bottom of the tank body is 0.5-0.8 times the height of the tank body, and the fallen leaf collecting and crushing device includes A collection box 7, the top of the collection box 7 is fixed with an exhaust fan 8, the inlet of the exhaust fan 8 communicates with the inner cavity of the collection box 7, and the outlet of the exhaust fan 8 is connected with a dust removal device. The dust removal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com